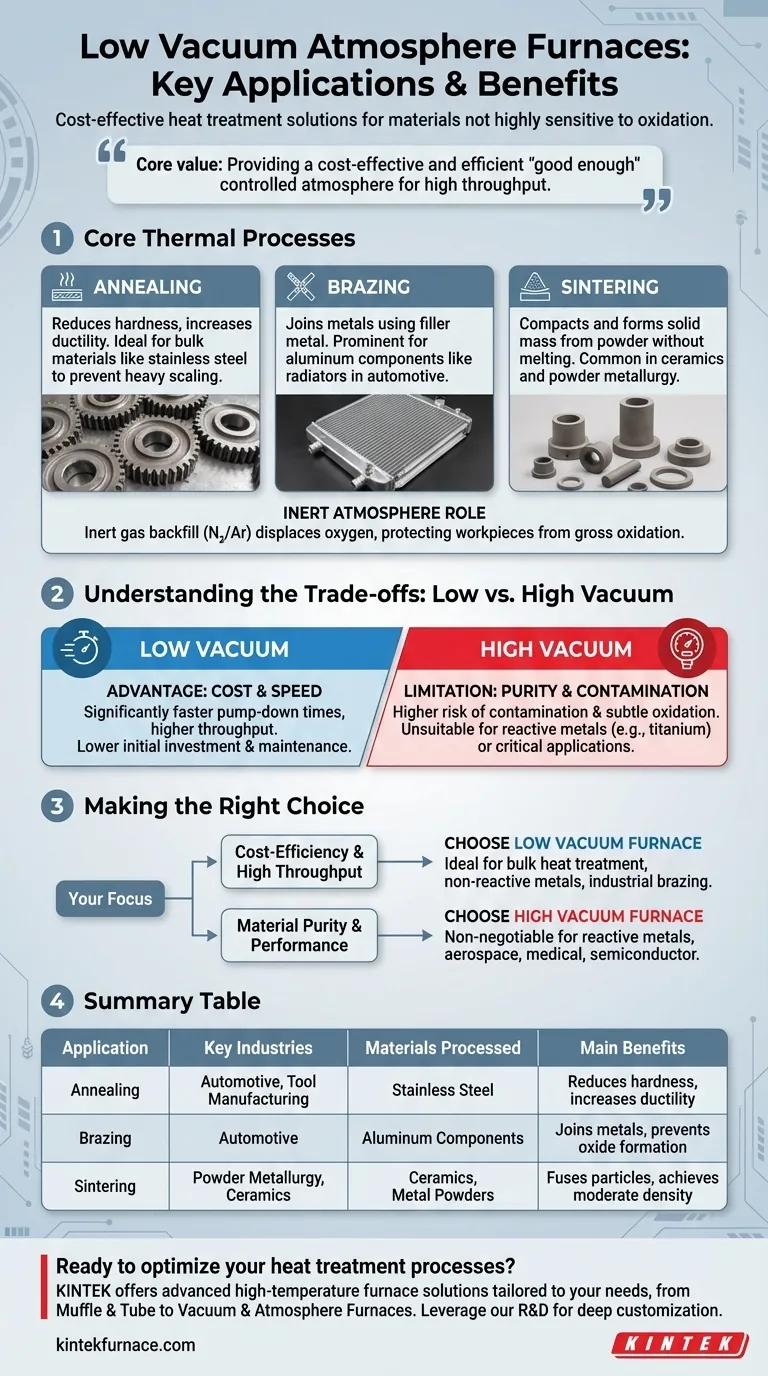

In short, low vacuum atmosphere furnaces are primarily used for heat treatment processes like annealing, brazing, and sintering on materials that are not highly sensitive to oxidation. They are the go-to solution for applications in the automotive and tool manufacturing industries where cost-effectiveness and processing speed are critical, such as for treating stainless steel, certain ceramics, and aluminum components.

The core value of a low vacuum furnace is not in achieving perfect purity, but in providing a cost-effective and efficient "good enough" controlled atmosphere. It strikes a crucial balance between preventing significant oxidation and maintaining high throughput for industrial-scale production.

Core Thermal Processes in Low Vacuum

Low vacuum furnaces excel at three primary thermal processes. The "low vacuum" is first used to remove most of the ambient air, after which the chamber is backfilled with an inert gas like nitrogen or argon. This creates a controlled, oxygen-poor atmosphere for processing.

Annealing

Annealing is a heat treatment process that alters a material's microstructure to reduce hardness, increase ductility, and relieve internal stresses. Low vacuum furnaces are ideal for annealing bulk materials like stainless steel parts where preventing heavy surface scaling is necessary, but trace oxidation is acceptable.

Brazing

Brazing joins two or more metal items by melting and flowing a filler metal into the joint. A prominent application is the brazing of aluminum components, such as radiators and heat exchangers in the automotive industry. The controlled atmosphere prevents the formation of oxides that would otherwise inhibit the flow of the brazing alloy.

Sintering

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. This is common in powder metallurgy and ceramics manufacturing. A low vacuum atmosphere furnace provides the necessary temperature and controlled environment to fuse the particles together for components where moderate density and purity are sufficient.

Understanding the Trade-offs: Low vs. High Vacuum

Choosing a low vacuum furnace is a strategic decision driven by a clear understanding of its benefits and limitations compared to more expensive high vacuum systems.

The Primary Advantage: Cost and Speed

The defining benefit of low vacuum systems is operational efficiency. Because they don't need to achieve an ultra-high vacuum, pump-down times are significantly faster, leading to higher throughput. The equipment is also simpler, resulting in lower initial investment and simpler, less costly maintenance.

The Critical Limitation: Purity and Contamination

The main trade-off is purity. A low vacuum environment, even when backfilled with inert gas, still contains residual oxygen and other molecules. This creates a higher risk of contamination and subtle oxidation, making these furnaces unsuitable for highly reactive metals like titanium or for applications in aerospace, medical, or semiconductor manufacturing where material purity is paramount.

The Role of the Inert Atmosphere

The primary function of the inert gas backfill (typically nitrogen or argon) is to displace the oxygen removed during the initial vacuum cycle. This inert "blanket" protects the workpiece from gross oxidation during the high-temperature process, which is the fundamental goal of this furnace type.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your material requirements, production goals, and budget.

- If your primary focus is cost-efficiency and high throughput: A low vacuum furnace is the ideal choice for bulk heat treatment of non-reactive metals and industrial-scale brazing.

- If your primary focus is material purity and performance: A high vacuum furnace is non-negotiable for processing reactive metals or manufacturing components for mission-critical applications.

Ultimately, the right choice is the one that meets your specific process requirements without the unnecessary cost and complexity of a higher-purity system.

Summary Table:

| Application | Key Industries | Materials Processed | Main Benefits |

|---|---|---|---|

| Annealing | Automotive, Tool Manufacturing | Stainless Steel | Reduces hardness, increases ductility, prevents heavy scaling |

| Brazing | Automotive | Aluminum Components | Joins metals, prevents oxide formation, ensures alloy flow |

| Sintering | Powder Metallurgy, Ceramics | Ceramics, Metal Powders | Fuses particles, achieves moderate density and purity |

Ready to optimize your heat treatment processes with a cost-effective solution? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in automotive, tool manufacturing, or other industries requiring efficient thermal processing, we can help you achieve higher throughput and reliability. Contact us today to discuss how our low vacuum atmosphere furnaces can benefit your operations!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab