To operate a muffle furnace effectively and safely, you must adhere to a strict set of procedures that protect both the operator and the equipment. The most critical actions include preheating the furnace to ensure uniform temperatures, using appropriate personal protective equipment (PPE) like heat-resistant gloves and eye protection, guaranteeing adequate ventilation, and following precise protocols for heating and cooling cycles. This disciplined approach ensures accurate results, equipment longevity, and personal safety.

The core principle of successful muffle furnace operation is not just managing extreme heat, but maintaining absolute control. This is achieved through methodical preparation, strict adherence to temperature protocols, and an unwavering commitment to safety at every step.

Foundational Setup and Preparation

Before you even turn the furnace on, proper setup is critical for safe and reliable operation. This foundation prevents common accidents and ensures your process starts correctly.

Ensure a Safe Workspace

Place the furnace on a stable, fireproof surface, such as a cement platform. The area must be equipped with the correct plugs, sockets, and fuses, and the furnace itself must be properly grounded.

Crucially, keep the workspace completely clear of any flammable, explosive, or corrosive substances.

Use the Correct Sample Containers

Only use high-temperature-resistant fixtures, such as ceramic or high-purity alumina crucibles and trays, to hold your samples. Using improper materials can lead to sample contamination or equipment damage at high temperatures.

Verify Temperature Accuracy

Periodically check the calibration of the furnace's temperature control system. An inaccurate controller can ruin samples and compromise the integrity of your results.

Mastering the Heating and Cooling Process

The way you heat and cool the furnace has a direct impact on your sample, the equipment, and your safety. A controlled process is a successful one.

Preheat Before Loading Samples

Always preheat the furnace to the desired temperature before loading your samples. This practice prevents thermal shock to the materials and ensures perfectly uniform heating.

Handle Samples with Care

When loading or unloading, place samples neatly in the center of the furnace chamber. This positioning promotes even heat distribution. Use appropriate tongs and always handle the furnace door gently to avoid damage.

Monitor the Operation

Never leave a furnace unattended while it is running. Watch for any abnormal temperature fluctuations or sounds, and be prepared to cut the power immediately if an issue arises.

Follow Proper Cooling Protocols

After the process is complete, turn off the main power. Once the temperature has dropped to a safe level, you can carefully remove the samples.

For controlled cooling, slightly open the furnace door. When the furnace is not in use, always cut the power and keep the door closed to protect the internal refractory materials from atmospheric moisture.

Understanding the Operational Limits and Trade-offs

A muffle furnace is a powerful tool with firm operational boundaries. Respecting these limits is non-negotiable for preventing catastrophic failure and ensuring a long service life.

Respect Maximum Temperature Limits

Never exceed the manufacturer's specified maximum temperature. Furthermore, avoid operating the furnace at its maximum rated temperature for extended periods, as this puts excessive strain on the heating elements and insulation.

Avoid Thermal Shock to the Furnace

As a critical rule, do not open the furnace door when the internal temperature is above 600°C. Abruptly introducing cool air can cause thermal shock, cracking the ceramic muffle or insulation and leading to costly repairs.

Prevent Internal Contamination and Damage

Never place liquids or samples containing significant amounts of water or oil directly into the furnace. Rapid vaporization can create pressure buildup, and spills can corrode the chamber floor and heating elements. Similarly, do not pour molten metals inside the furnace.

Prioritize Personal and Environmental Safety

Always wear essential PPE, especially heat-resistant gloves and safety glasses or a face shield, when working near the furnace. The risk of severe burns is extremely high.

Ensure the room has excellent ventilation, particularly when performing processes like ashing or incineration that release fumes or smoke. A dedicated fume hood is often required.

Finally, keep the furnace chamber clean by regularly removing any residue or debris. This prevents cross-contamination of samples and maintains the furnace's heating efficiency.

Making the Right Choice for Your Goal

Your operational focus will determine which procedures are most critical to emphasize during your work.

- If your primary focus is sample integrity and accuracy: Prioritize preheating the furnace, confirming temperature calibration, and using spotlessly clean, appropriate crucibles.

- If your primary focus is equipment longevity: Emphasize respecting temperature limits, following controlled cooling procedures, and keeping the furnace chamber immaculate.

- If your primary focus is operator safety: The non-negotiable use of PPE, ensuring proper ventilation, and maintaining a clear, secure workspace are your most important duties.

Ultimately, disciplined and informed operation is the key to unlocking the full potential of your muffle furnace safely and effectively.

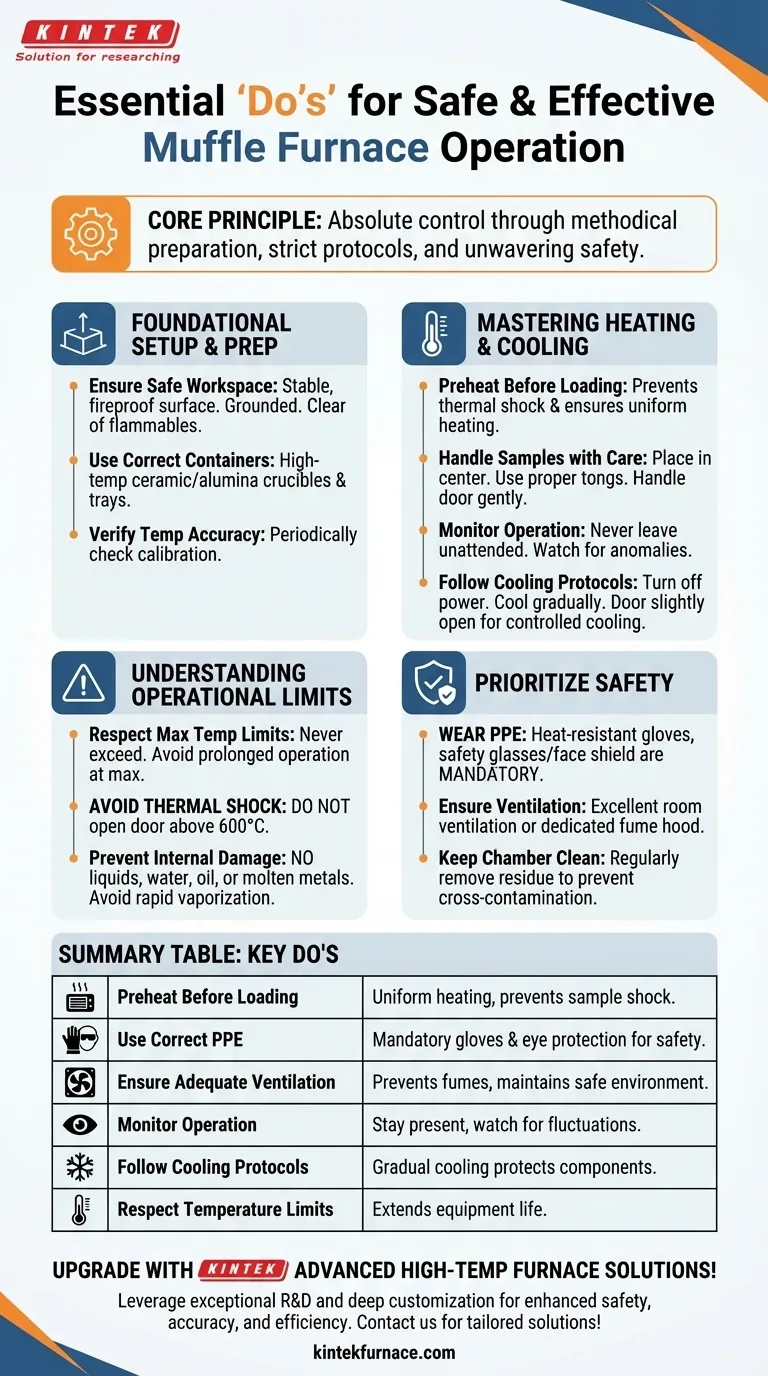

Summary Table:

| Key Do's | Description |

|---|---|

| Preheat Before Loading | Ensures uniform heating and prevents thermal shock to samples. |

| Use Correct PPE | Wear heat-resistant gloves and eye protection for operator safety. |

| Ensure Adequate Ventilation | Prevents fume buildup and maintains a safe environment. |

| Monitor Operation | Never leave unattended; watch for temperature fluctuations. |

| Follow Cooling Protocols | Turn off power and cool gradually to protect furnace components. |

| Respect Temperature Limits | Avoid exceeding max temperature to extend equipment life. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced safety, accuracy, and efficiency. Contact us today to discuss how we can support your operations and deliver tailored solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment