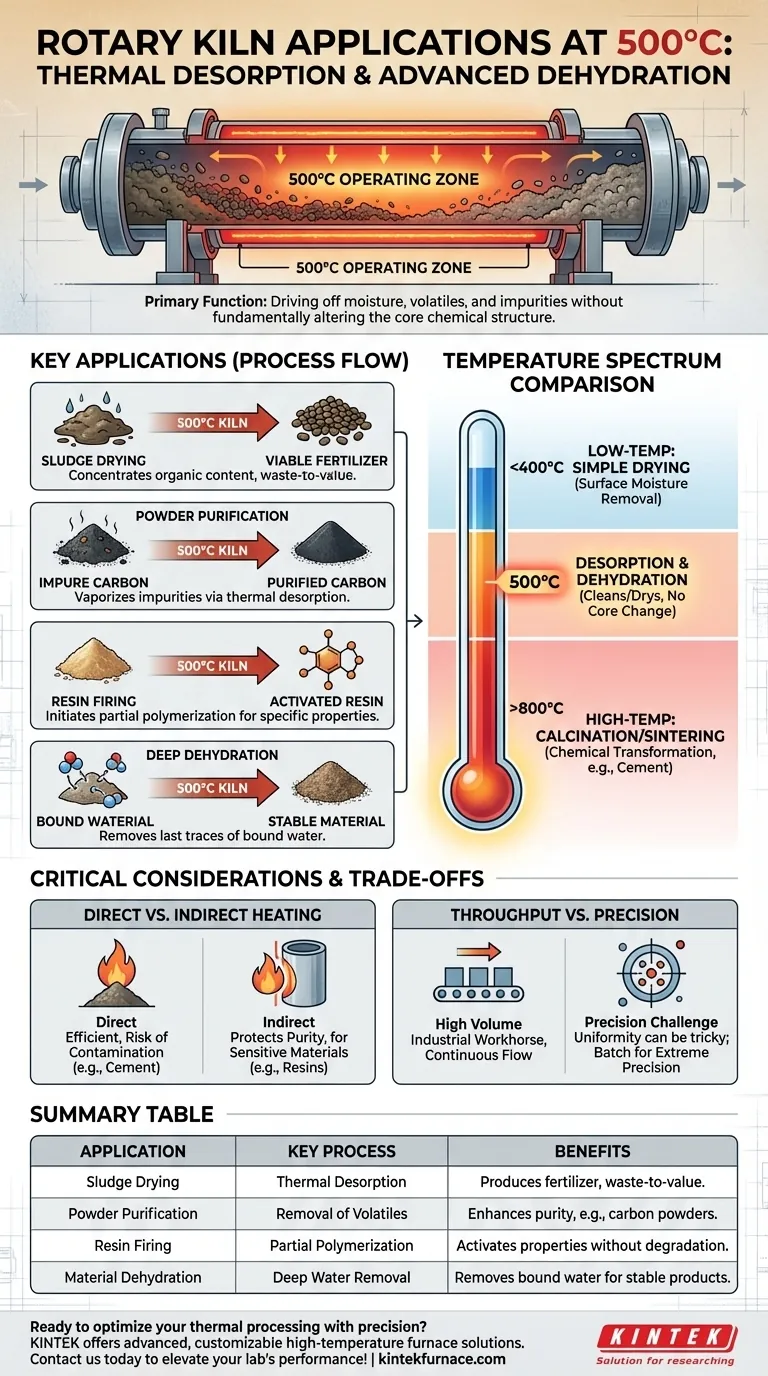

At 500°C, a rotary kiln's primary function is thermal desorption and advanced dehydration. This temperature is ideal for processes that drive off moisture, volatile compounds, and impurities without fundamentally altering the core chemical structure of the material itself. Common applications include drying sludge to create fertilizer, purifying carbon powder by removing contaminants, firing resin powders to activate specific properties, and dehydrating materials to remove the last traces of bound water.

The specific temperature of a rotary kiln process is more important than the kiln itself. A 500°C process occupies a critical middle ground—hot enough to trigger desorption and remove stubborn moisture, but below the intense heat required for calcination or sintering seen in cement and metallurgy.

The Role of Temperature in Thermal Processing

A rotary kiln is essentially a rotating, cylindrical furnace designed to heat solids to a precise temperature and induce a desired physical or chemical change. The application is defined entirely by the temperature reached and the material being processed.

The 500°C Threshold: Desorption and Dehydration

This temperature range is primarily used for processes that "clean" or "dry" a material.

For sludge drying, the 500°C heat efficiently evaporates water, concentrating the organic and nutrient content to produce a viable fertilizer. This is a highly effective waste-to-value process.

For powder purification, such as with carbon, the heat is sufficient to vaporize and remove volatile impurities or residual solvents. This process, known as thermal desorption, is also the core principle behind remediating contaminated soils.

For firing resin powders, this temperature can initiate specific chemical reactions like partial polymerization, which adds functionality or desired characteristics to the final product without causing it to combust or degrade.

Contrasting with Other Temperature Ranges

The 500°C mark becomes clearer when compared to other kiln operations.

Low-temperature processes (<400°C) are typically used for simple drying, where only unbound surface moisture is being removed from a stable material.

High-temperature processes (>800°C) are where fundamental chemical transformations occur. This includes calcination, where materials like limestone are converted to lime (~900°C), and the production of cement clinker (>1450°C). These processes create entirely new chemical compounds.

Understanding the Trade-offs and Considerations

While powerful, rotary kilns are not a universal solution. The design and operating parameters must match the goal.

Direct vs. Indirect Heating

This is the most critical distinction for processes around 500°C.

In a direct-fired kiln, the flame and combustion gases are in direct contact with the material. This is highly efficient but risks contaminating sensitive products. It is best suited for robust, high-temperature applications like cement and lime.

In an indirect-fired kiln, the cylinder is heated from the outside, and the material inside never touches the flame. This is essential for processing delicate materials, preventing unwanted side reactions, and ensuring product purity, making it ideal for many 500°C applications like resin firing or specialty chemical production.

Throughput vs. Precision

Rotary kilns are prized for their ability to process a continuous, high-volume flow of material, making them industrial workhorses.

However, achieving a perfectly uniform temperature for every particle within the tumbling bed of material can be a challenge. For applications requiring extreme thermal precision, a smaller batch-style furnace may be more appropriate, though at the cost of throughput.

Feedstock Flexibility

A major advantage of rotary kilns is their ability to handle a wide variety of feedstock types, from fine powders and sludges to granular solids and even scrap materials. Their heavy-duty construction ensures a long service life even in demanding environments.

Making the Right Choice for Your Goal

To select the correct thermal process, you must first define your desired material transformation.

- If your primary focus is removing water or volatile contaminants: A process near 500°C is ideal for thermal desorption and deep dehydration without fundamentally changing the base material.

- If your primary focus is creating new mineral structures (like cement): You require a much higher temperature calcination process (typically >900°C) that forces a complete chemical reaction.

- If your primary focus is processing a sensitive material that cannot be contaminated: An indirect-fired kiln is non-negotiable to protect product purity and control the atmosphere.

Matching the thermal process to your material's specific transformation point is the key to successful industrial heating.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Sludge Drying | Thermal Desorption | Produces fertilizer, waste-to-value |

| Powder Purification | Removal of Volatiles | Enhances purity, e.g., carbon powders |

| Resin Firing | Partial Polymerization | Activates properties without degradation |

| Material Dehydration | Deep Water Removal | Removes bound water for stable products |

Ready to optimize your thermal processing with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need efficient sludge drying or pure powder processing, we deliver tailored solutions for superior results. Contact us today to discuss your needs and elevate your lab's performance!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency