At its core, a rotary furnace is a specialized industrial or laboratory oven designed for continuous thermal processing. It consists of a long, rotating cylindrical tube, often slightly inclined, that tumbles material through multiple, precisely controlled heating zones. This unique design ensures every particle of the material is exposed to the same temperature for the same amount of time, achieving a level of uniformity that is difficult to match with static furnace designs.

The fundamental advantage of a rotary furnace is its ability to solve the problem of inconsistent heating. By continuously mixing the material, it guarantees uniform temperature exposure, making it the ideal solution for processing powders, pellets, and other granular substances that require precise thermal treatment.

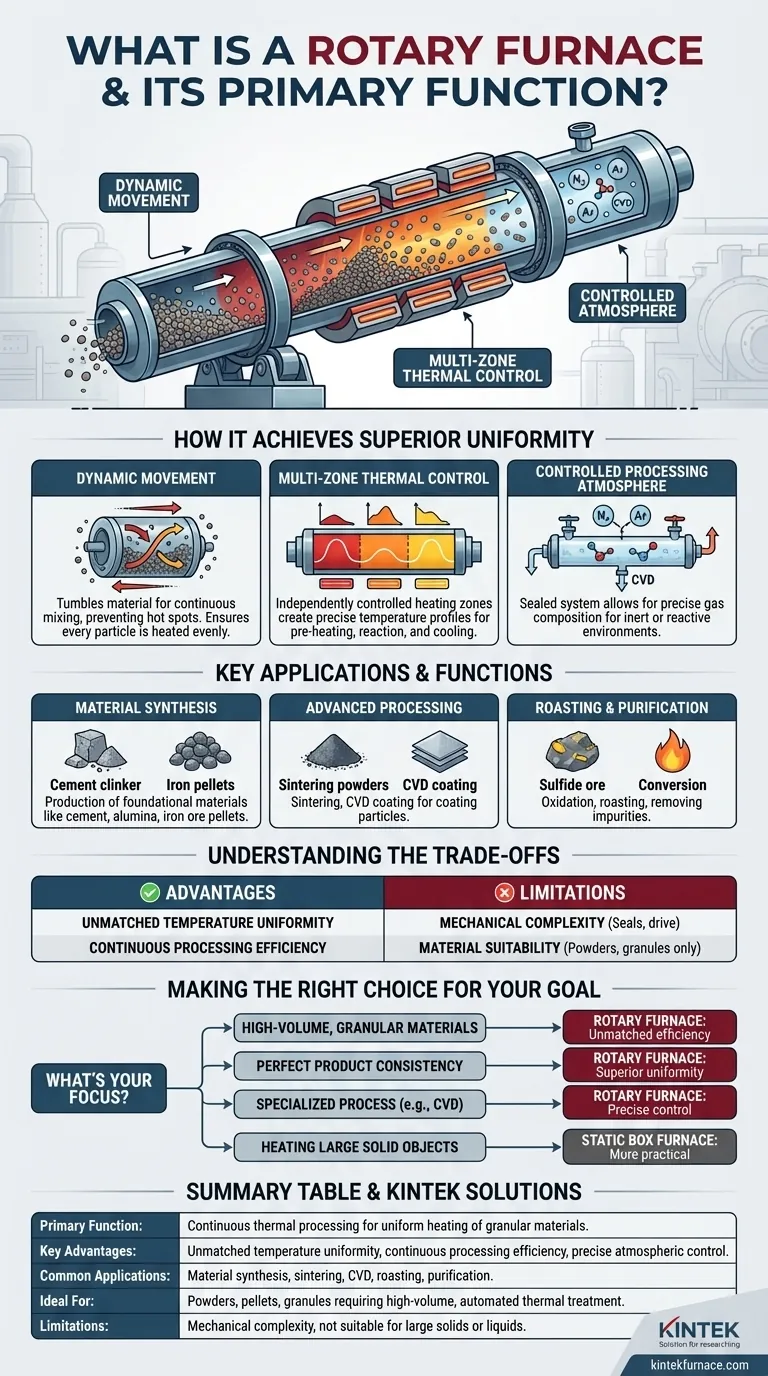

How a Rotary Furnace Achieves Superior Uniformity

The effectiveness of a rotary furnace comes from the synergy of three key design principles: dynamic movement, zonal heating, and atmospheric control.

The Principle of Dynamic Movement

A rotary furnace’s tube is mounted on rollers and rotates slowly around its longitudinal axis. This rotation continuously lifts and tumbles the material inside.

This constant mixing action prevents hot spots and ensures that the entire batch of material is heated evenly. When the tube is set at a slight incline, gravity assists in moving the material from the entry point to the exit, enabling a continuous, automated process.

Multi-Zone Thermal Control

The furnace is heated externally by elements that are typically divided into several distinct thermal zones along the length of the tube.

Each zone can be controlled independently to create a precise temperature profile. For example, a material can be gradually pre-heated in the first zone, held at a peak reaction temperature in the middle zones, and then cooled in the final zone before discharge.

Controlled Processing Atmosphere

Many rotary furnaces are sealed systems, allowing for precise control over the gas composition inside the tube.

This enables processes that must occur in a specific atmosphere, such as an inert environment (using nitrogen or argon) to prevent oxidation, or a reactive one (using specific gases) for processes like chemical vapor deposition (CVD).

Key Applications and Functions

The unique capabilities of rotary furnaces make them indispensable across a wide range of industries for specific, high-stakes thermal processes.

Material Synthesis and Production

This is a primary function for large-scale industrial operations. Rotary furnaces are used to manufacture foundational materials by causing chemical or physical changes through heat.

Key examples include producing cement clinker, calcining alumina, and creating iron ore pellets for steel manufacturing.

Advanced Materials Processing

In more technical applications, rotary furnaces are used for processes that require extreme precision.

Sintering, where fine powders are heated to bond together into a solid mass without melting, is a common use. Similarly, their atmospheric control makes them suitable for coating particles via chemical vapor deposition (CVD).

Roasting and Purification

Rotary furnaces are also used to purify materials or prepare them for further processing.

This includes oxidation and roasting, where materials are heated in the presence of air or oxygen to induce a chemical change, such as converting sulfide ores into oxides.

Understanding the Trade-offs

While highly effective, the rotary furnace is a specialized tool with specific advantages and limitations compared to other thermal systems.

Advantage: Unmatched Temperature Uniformity

The continuous tumbling of the material is the single greatest advantage. It eliminates the inconsistencies and quality issues that can arise from uneven heating in static box or belt furnaces.

Advantage: Continuous Processing Efficiency

The design is inherently suited for continuous, automated production. This significantly reduces material handling requirements and labor costs in high-volume settings compared to processing individual batches in a static furnace.

Limitation: Mechanical Complexity

The rotating mechanism, including the drive system, support rollers, and particularly the seals at each end of the tube, adds mechanical complexity. These components require more maintenance than a simple static furnace.

Limitation: Material Suitability

Rotary furnaces are designed almost exclusively for processing powders, granules, pellets, and other loose, free-flowing materials. They are not suitable for processing large, single solid objects or liquids.

Making the Right Choice for Your Goal

The decision to use a rotary furnace hinges entirely on your material type and desired process outcome.

- If your primary focus is high-volume production of granular materials: The continuous processing capability of a rotary furnace offers unmatched efficiency and automation.

- If your primary focus is achieving perfect product consistency: The dynamic rotation ensures every particle receives the same thermal exposure, delivering superior uniformity.

- If your primary focus is a specialized chemical process like CVD or controlled oxidation: The ability to precisely manage both temperature zones and the internal atmosphere makes a rotary furnace the ideal choice.

- If your primary focus is simply heating a large, solid object: A static box furnace or a different furnace type would be a more practical and cost-effective solution.

Ultimately, a rotary furnace is an engineered solution designed to master the complex challenge of uniform heating for dynamic materials.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | Continuous thermal processing for uniform heating of granular materials |

| Key Advantages | Unmatched temperature uniformity, continuous processing efficiency, precise atmospheric control |

| Common Applications | Material synthesis (e.g., cement, iron pellets), sintering, CVD, roasting, and purification |

| Ideal For | Powders, pellets, granules requiring high-volume, automated thermal treatment |

| Limitations | Mechanical complexity, not suitable for large solids or liquids |

Unlock Precision in Your Thermal Processes with KINTEK

Struggling with inconsistent heating in your material processing? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental and production requirements, delivering superior uniformity and efficiency for granular materials.

Ready to enhance your lab's performance? Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation