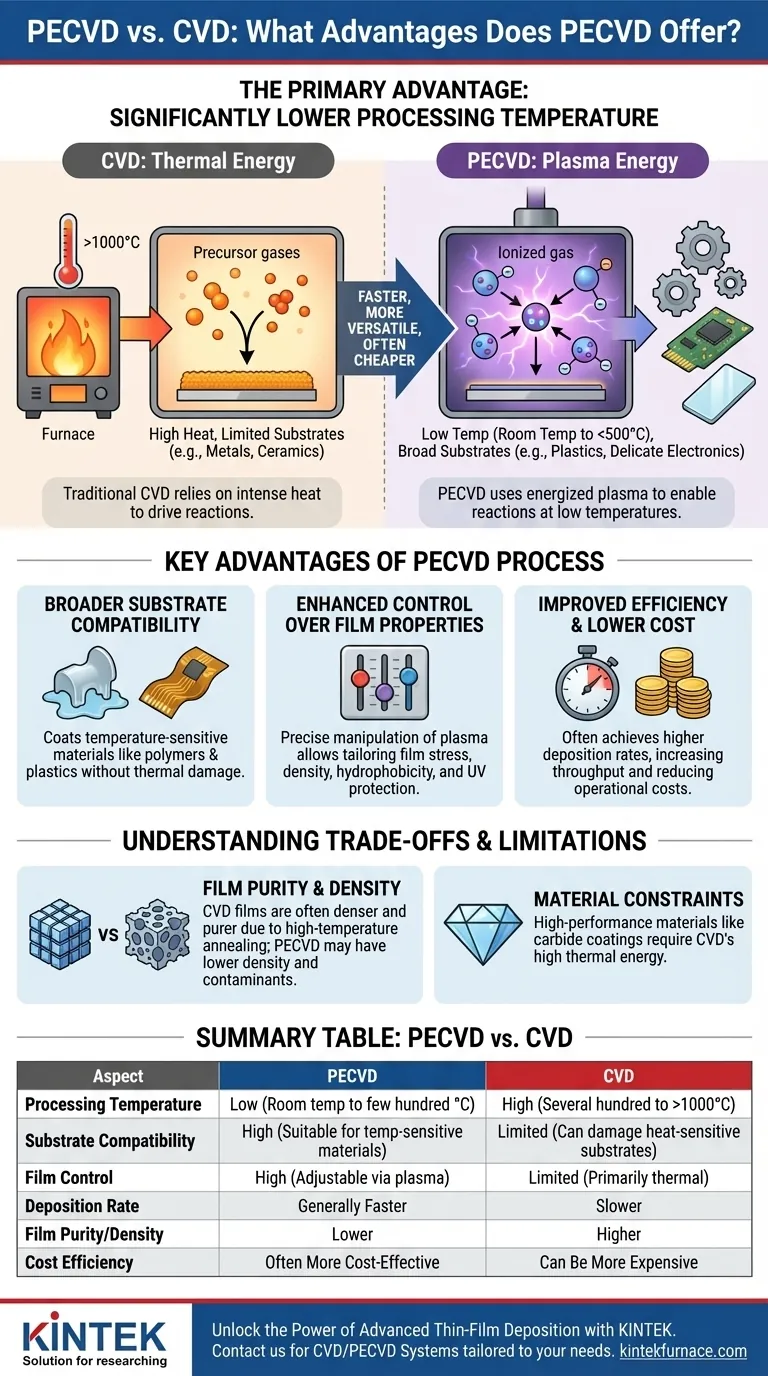

The primary advantage of PECVD is its significantly lower processing temperature compared to traditional Chemical Vapor Deposition (CVD). By using an energized plasma to drive chemical reactions instead of high heat, PECVD can deposit thin films on a much wider range of materials, including temperature-sensitive substrates like plastics or partially fabricated electronic devices that would be damaged by the extreme heat of conventional CVD.

While both CVD and PECVD create high-quality thin films, the core difference is the energy source. PECVD's use of plasma decouples the reaction from heat, making it a faster, more versatile, and often cheaper process suitable for modern, heat-sensitive applications.

The Fundamental Difference: Plasma vs. Heat

To understand the advantages of PECVD, you must first understand how each process drives the film deposition reaction. The choice of energy source is the root of all subsequent differences in performance, cost, and application.

How Traditional CVD Works

Traditional CVD relies purely on thermal energy. Precursor gases are introduced into a high-temperature furnace, typically operating from several hundred to over a thousand degrees Celsius.

This intense heat provides the activation energy needed for the gases to react and decompose, depositing a solid, thin film onto the surface of a substrate.

How PECVD Works

PECVD (Plasma-Enhanced Chemical Vapor Deposition) replaces high heat with plasma as the energy source. An electrical field is used to ionize a gas, creating a reactive environment of electrons, ions, and free radicals.

These high-energy particles collide with the precursor gases, breaking them down and enabling the deposition reaction to occur at much lower temperatures—from room temperature up to just a few hundred degrees Celsius.

Key Advantages of the PECVD Process

The ability to operate at low temperatures creates several significant downstream benefits, making PECVD a preferred choice for many modern manufacturing and research applications.

Broader Substrate Compatibility

The most critical advantage is the ability to coat temperature-sensitive materials. The high heat of CVD would destroy or compromise substrates like polymers, plastics, and complex semiconductor devices with pre-existing components.

PECVD’s low-temperature nature makes it the only viable option for applying functional coatings to these materials without causing thermal damage.

Enhanced Control Over Film Properties

The plasma in a PECVD system adds an extra "control knob" that does not exist in thermal CVD. By adjusting factors like power, pressure, and gas composition, you can precisely manipulate the plasma environment.

This allows for a high degree of tailorability in the final film properties. Engineers can fine-tune characteristics such as film stress, density, chemical composition, hydrophobicity, or UV protection.

Improved Efficiency and Lower Cost

PECVD processes often achieve higher deposition rates than their thermal CVD counterparts. This increased speed directly translates to higher throughput and lower operational costs.

Furthermore, the ability to use different, sometimes cheaper, precursor gases that may not be suitable for high-temperature processes can also contribute to overall cost savings.

Understanding the Trade-offs and Limitations

No technology is without its compromises. While powerful, PECVD has specific limitations that make traditional CVD a better choice for certain applications.

Film Purity and Density

Because traditional CVD operates at such high temperatures, the deposited film is continuously annealed during the process. This can result in films with higher purity, greater density, and a more crystalline structure.

PECVD films, being deposited at low temperatures, can sometimes be less dense or have more contaminants (like hydrogen) incorporated, which may impact wear resistance or barrier performance in demanding situations.

Material Constraints

Certain high-performance materials and coatings simply require the high thermal energy of CVD to form the correct chemical bonds and crystal structure.

For applications demanding the hardest, most resilient films (like certain carbide or nitride tool coatings), the high-temperature CVD process remains the industry standard.

Process Complexity

While the plasma provides greater control, it also adds a layer of complexity to the process. Managing the plasma physics and chemistry requires sophisticated equipment and deep process knowledge to achieve consistent and repeatable results.

Making the Right Choice for Your Application

Selecting the correct deposition method requires a clear understanding of your primary goal. The trade-off between low-temperature versatility and high-temperature film quality is the central consideration.

- If your primary focus is coating temperature-sensitive materials: PECVD is the definitive and often only choice due to its low-temperature operation.

- If your primary focus is maximum film purity, density, and hardness: Traditional CVD is often superior, as the high heat promotes a more ideal film structure.

- If your primary focus is process speed and cost-effectiveness for a compatible material: PECVD generally offers faster deposition rates and higher throughput.

- If your primary focus is tuning unique film properties like low stress or hydrophobicity: PECVD provides more variables to control and tailor the final outcome.

By understanding this core trade-off between thermal energy and plasma activation, you can confidently select the deposition method that aligns with your material, performance, and budget requirements.

Summary Table:

| Aspect | PECVD | CVD |

|---|---|---|

| Processing Temperature | Low (room temp to a few hundred °C) | High (several hundred to over 1000°C) |

| Substrate Compatibility | High (suitable for temperature-sensitive materials like plastics) | Limited (can damage heat-sensitive substrates) |

| Film Control | High (adjustable via plasma parameters) | Limited (primarily thermal control) |

| Deposition Rate | Generally faster | Slower |

| Film Purity/Density | Lower (may have contaminants) | Higher (due to high-temperature annealing) |

| Cost Efficiency | Often more cost-effective | Can be more expensive due to energy use |

Unlock the Power of Advanced Thin-Film Deposition with KINTEK

Are you working with temperature-sensitive materials or need precise control over film properties? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements.

Contact us today to discuss how our PECVD and CVD systems can enhance your lab's efficiency and drive innovation in your projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition