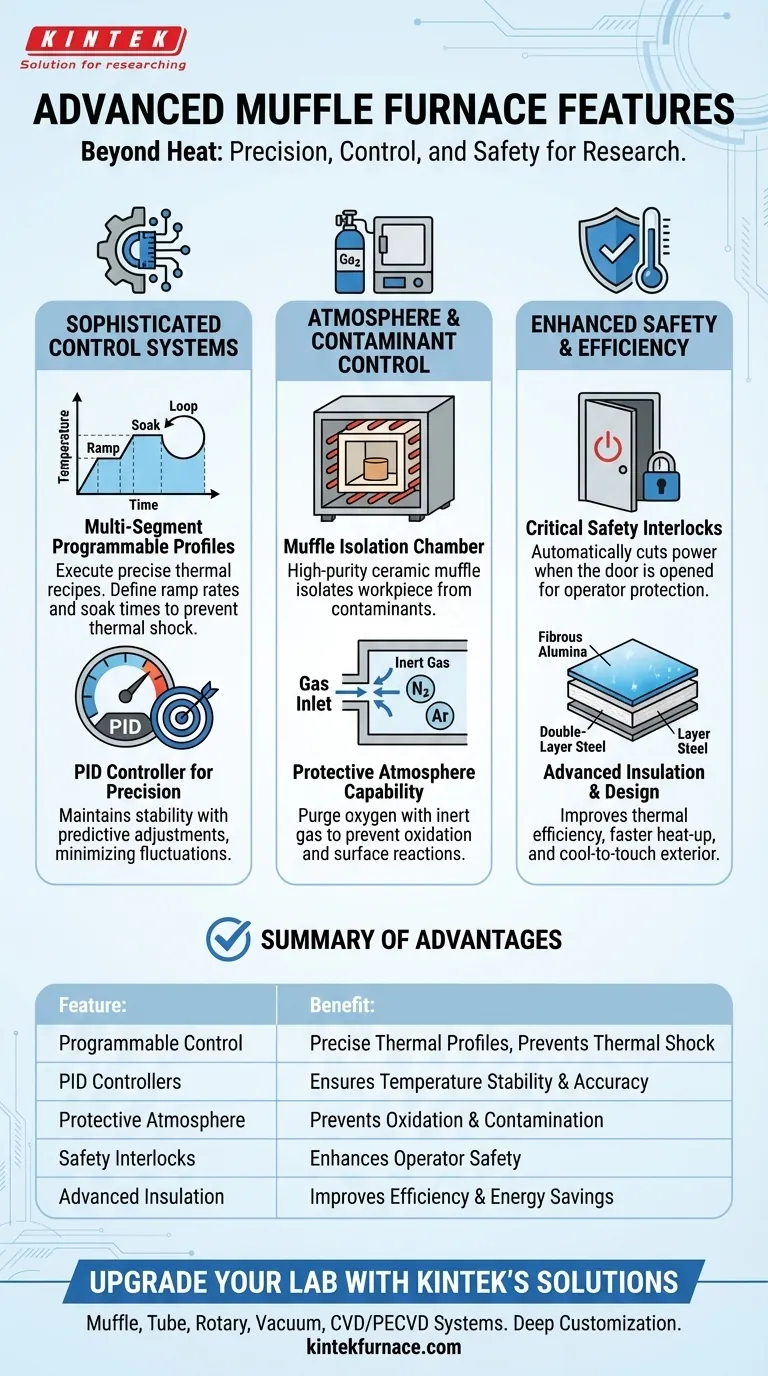

Beyond simple heating, advanced muffle furnaces are distinguished by their sophisticated control systems and specialized environmental capabilities. Key features include multi-segment programmable controllers that execute precise thermal profiles, the ability to introduce a protective atmosphere to prevent oxidation, and enhanced safety interlocks for secure operation.

The leap from a basic to an advanced muffle furnace is not about reaching higher temperatures, but about gaining precise, repeatable control over the entire heating and cooling process. These features exist to protect sensitive materials and ensure the integrity of your results.

The Core of Advanced Control: Programmable Thermal Profiles

The most significant advancement in modern muffle furnaces is the move from a single temperature setting to dynamic, multi-step process control.

Beyond Single Setpoints

Basic furnaces are set to a target temperature and hold it. Advanced models allow you to control the entire thermal journey of your sample.

The Power of Multi-Segment Programs

This feature, often described as 30-segment programmable control, allows you to create a detailed heating and cooling recipe. You can precisely define ramp rates (how fast the temperature rises or falls), soak times (how long it stays at a temperature), and loop these steps.

This is critical for preventing thermal shock in materials like ceramics or for complex metallurgical processes that require specific, timed temperature changes.

How PID Controllers Ensure Precision

Advanced furnaces use a PID (Proportional-Integral-Derivative) controller to maintain temperature stability. This system constantly monitors the temperature and makes tiny, predictive adjustments to the power output, preventing the overshooting and undershooting common in simpler on/off systems. This ensures the temperature you set is the temperature you get, with minimal fluctuation.

Protecting Your Sample: Atmosphere and Contaminant Control

A key function of a muffle furnace is isolation. Advanced models take this principle a step further by managing the gaseous environment within the chamber.

The Role of the Muffle

The "muffle" itself is an interior chamber, often made of high-purity ceramic, that isolates the workpiece from direct contact with the heating elements. This prevents contamination from flaking element materials.

Introducing a Protective Atmosphere

Many advanced models include a gas inlet port. This allows you to purge the chamber of oxygen and introduce an inert gas like nitrogen or argon. Creating this protective atmosphere is essential for any process where oxidation or surface reactions on the sample must be avoided.

Ensuring Consistency and Safety

Beyond temperature control, advanced furnaces incorporate design features that improve uniformity, safety, and efficiency.

Achieving True Temperature Uniformity

While all furnaces aim for even heating, advanced models employ specific strategies like placing heating elements on multiple sides of the chamber. This ensures that a large sample or multiple small samples experience the same thermal conditions, leading to more consistent and reliable results.

Critical Safety Interlocks

A key advanced feature is a safety interlock on the door. This automatically cuts power to the heating elements when the door is opened, protecting the user from extreme heat and the elements from thermal shock. Over-temperature protection is another feature that shuts the furnace down if it exceeds a set safety limit.

Advanced Insulation and Construction

Modern furnaces often use high-purity fibrous alumina insulation instead of traditional firebrick. This material offers better thermal efficiency, allowing for faster heat-up times and lower energy consumption.

A double-layer steel structure with an integrated cooling fan keeps the external surface of the furnace cool to the touch, significantly enhancing operator safety in a lab environment.

Understanding the Trade-offs

While advanced features offer superior control, they come with practical considerations that must be balanced against your needs.

Cost vs. Capability

There is a significant cost difference between a simple, single-setpoint furnace and one with multi-segment programming and atmosphere control. It is crucial to justify the added expense based on the specific requirements of your application.

Complexity vs. Usability

A highly programmable controller offers immense flexibility but also has a steeper learning curve. For a lab where simplicity and rapid turnover are key, a simpler interface might be more practical than a feature-rich but complex one.

Maintenance and Consumables

Features like atmosphere control introduce new operational needs. You must factor in the ongoing cost and logistics of purchasing and handling compressed gas cylinders. More complex controllers may also require specialized servicing if they fail.

Selecting the Right Features for Your Application

Choosing a furnace requires aligning its capabilities with your primary goal.

- If your primary focus is basic ashing or simple heat treatments: A furnace with reliable PID control and a single setpoint is likely sufficient and cost-effective.

- If you are working with sensitive ceramics or complex material cycles: A furnace with multi-segment programmable controls is essential to manage thermal shock and execute precise processes.

- If you need to prevent any oxidation or surface reactions: A model with a gas inlet port for creating a protective atmosphere is non-negotiable.

- If you operate in a high-throughput or multi-user environment: Prioritize models with robust safety features like door interlocks and over-temperature protection to ensure operator safety.

Ultimately, understanding these advanced features empowers you to invest in a tool that truly fits the complexity and precision of your work.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Multi-Segment Programmable Control | Enables precise thermal profiles and prevents thermal shock |

| PID Controllers | Ensures temperature stability and accuracy |

| Protective Atmosphere Capability | Prevents oxidation and contamination of samples |

| Safety Interlocks | Enhances operator safety by cutting power when door opens |

| Advanced Insulation | Improves thermal efficiency and energy savings |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your needs. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, boosting efficiency and reliability. Contact us today to discuss how we can enhance your processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization