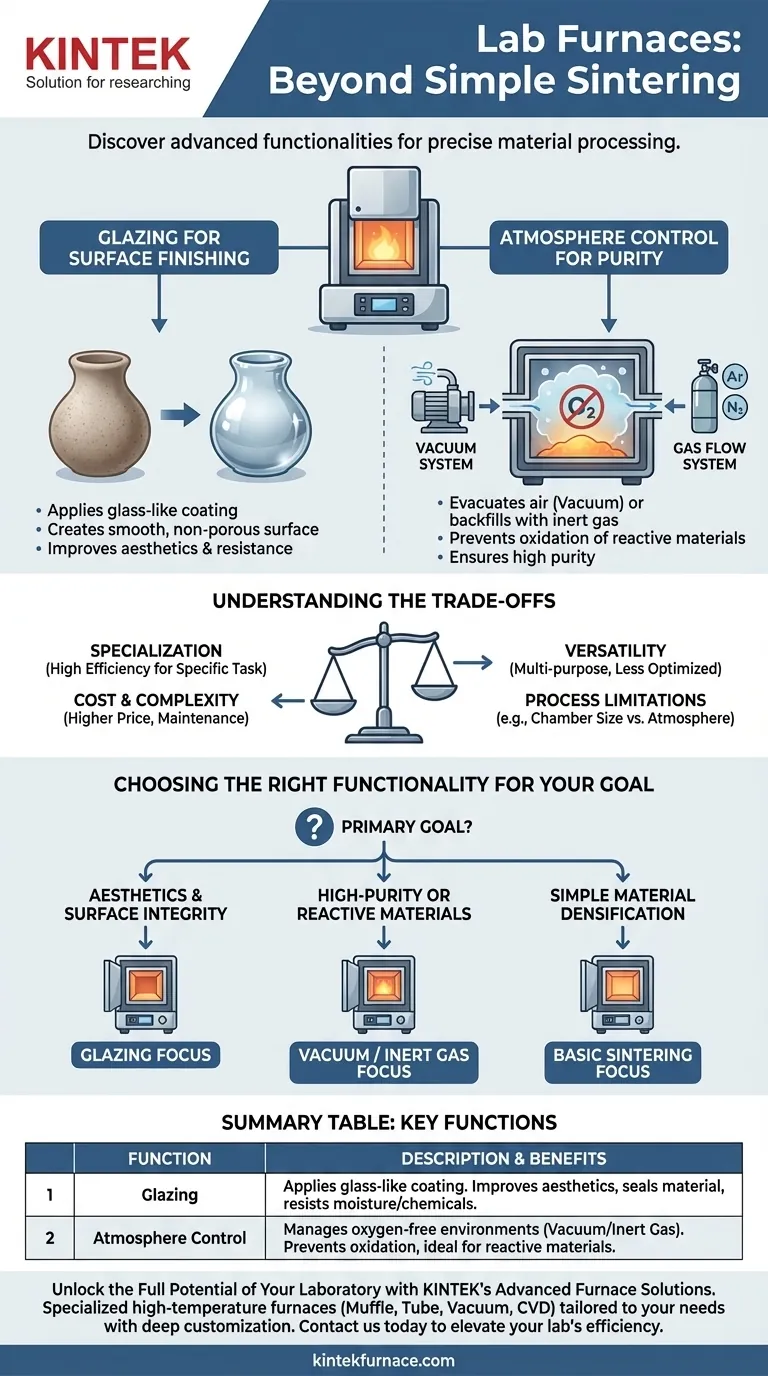

Beyond simple heating, modern laboratory furnaces are sophisticated instruments capable of more than just sintering materials. The most common additional functionalities include glazing for surface finishing and precise atmosphere control for processing sensitive materials in an oxygen-free environment. These features are not mere add-ons; they are critical for achieving specific material properties and finishes.

A lab furnace's value extends far beyond raw heat. Its true utility is defined by its ability to precisely control the processing environment, enabling advanced functions like surface glazing and high-purity material synthesis that sintering alone cannot accomplish.

Beyond Sintering: Key Additional Functions

While sintering—the process of densifying a material using heat—is a primary function, many lab furnaces are designed for more nuanced tasks. These capabilities transform the furnace from a simple oven into a multi-purpose material processing tool.

Glazing for Surface Finishing

Glazing involves applying a vitreous, or glass-like, coating to a material's surface. This is a distinct, lower-temperature process that often follows an initial sintering stage.

The primary purpose of glazing is to create a smooth, non-porous, and aesthetically pleasing surface. This seals the underlying material, improving its resistance to moisture and chemical attack while enhancing its final appearance.

Atmosphere Control for Material Purity

Many advanced materials are highly reactive with oxygen, especially at elevated temperatures. Atmosphere control is a critical function for processing these materials without causing unwanted oxidation or contamination.

This is typically achieved in two ways. A vacuum system can be used to evacuate the air from the furnace chamber, while a gas flow system can backfill the chamber with a protective, inert gas like argon or nitrogen to create an oxygen-free environment. Tube furnaces are commonly equipped for this.

Understanding the Trade-offs

Adding functionality introduces complexity and cost. Selecting a furnace requires balancing its capabilities with your specific needs and operational realities.

Specialization vs. Versatility

A furnace designed to do everything may not perform a single task as efficiently as a specialized unit. A furnace optimized for high-vacuum, high-purity processing might have limitations in chamber size or ramp rate compared to a large-capacity air-sintering furnace.

Cost and Complexity

Each additional feature increases the initial purchase price and ongoing maintenance. A vacuum system requires pumps, seals, and gauges that need regular service. Gas flow systems require a steady supply of high-purity gas and regulators.

Process Limitations

The physical design of the furnace often dictates its best use. For example, tube furnaces are ideal for atmosphere control due to their easily sealed geometry, but they offer a smaller and more restrictive processing volume than a typical box furnace used for bulk sintering.

Choosing the Right Functionality for Your Goal

The right furnace is the one that directly supports your primary objective. Evaluate your needs to determine which features are essential and which are unnecessary complexities.

- If your primary focus is aesthetics and surface integrity: Prioritize a furnace with reliable low-temperature control and dedicated glazing cycles.

- If your primary focus is high-purity or reactive materials: A furnace with integrated vacuum and inert gas flow capabilities is non-negotiable.

- If your primary focus is simple material densification: A basic, robust sintering furnace without complex atmosphere controls may be the most reliable and cost-effective solution.

Understanding these functions allows you to select a furnace that is not just a tool, but a precise solution for your material processing needs.

Summary Table:

| Function | Description | Key Benefits |

|---|---|---|

| Glazing | Applies a glass-like coating to surfaces | Improves aesthetics, seals material, and resists moisture/chemicals |

| Atmosphere Control | Manages oxygen-free environments using vacuum or inert gases | Prevents oxidation, ideal for reactive materials |

Unlock the Full Potential of Your Laboratory with KINTEK's Advanced Furnace Solutions

Are you looking to enhance your material processing with precise glazing or atmosphere control? KINTEK specializes in providing high-temperature furnaces tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're working with reactive materials or need superior surface finishes.

Don't settle for basic sintering—elevate your lab's efficiency and results. Contact us today to discuss how our solutions can drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control