Beyond the primary function of sintering, the most common additional capability offered by some dental furnaces is glazing. This lower-temperature process is essential for creating the smooth, non-porous, and aesthetically pleasing final surface on a dental restoration. However, whether a single furnace can perform both tasks depends entirely on its design and intended purpose.

The term "dental furnace" is not one-size-fits-all. The functionality of a furnace is dictated by the materials it's designed to process. High-temperature sintering furnaces are built for zirconia, while lower-temperature ceramic furnaces handle processes like glazing and firing conventional porcelain.

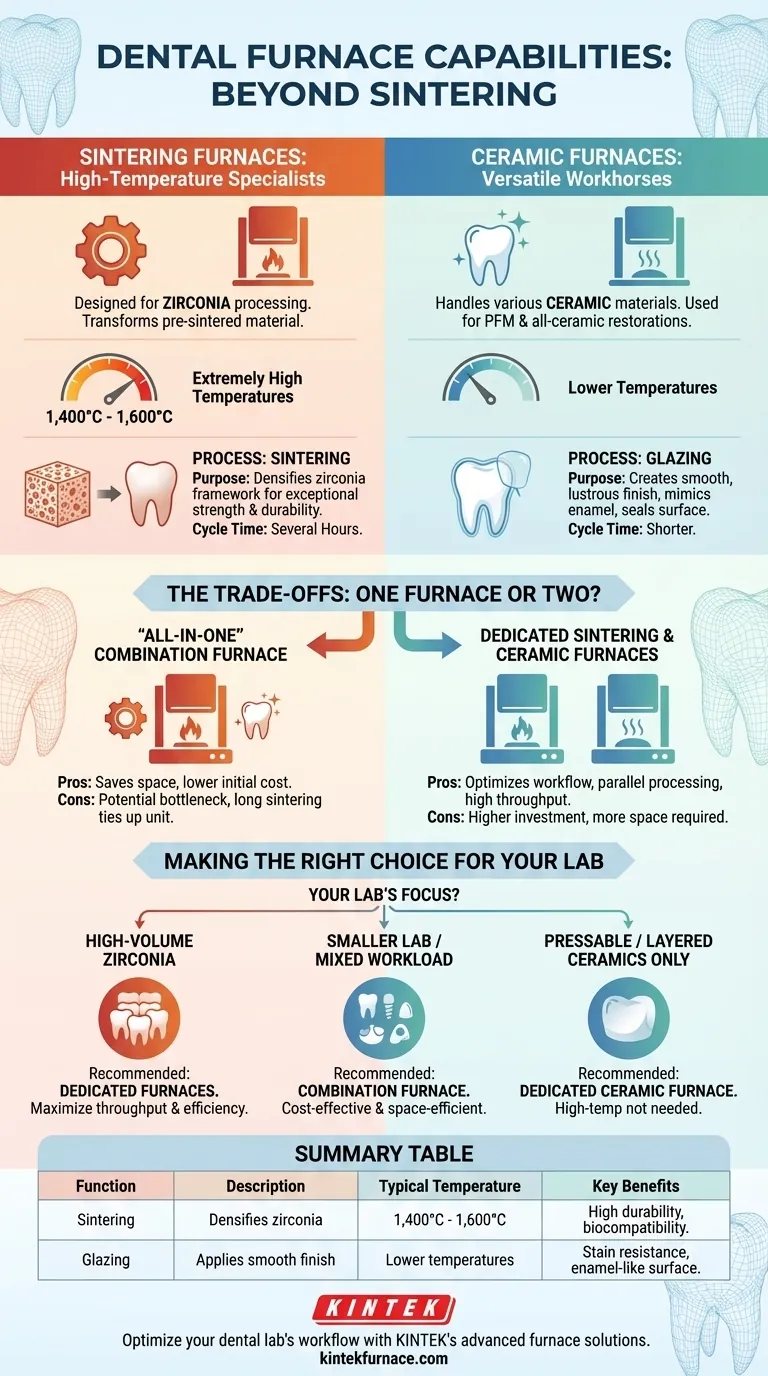

The Two Core Types of Dental Furnaces

To understand a furnace's capabilities, you must first distinguish between the two primary categories. They are not interchangeable, as each is engineered for specific materials and temperature ranges.

Sintering Furnaces: The High-Temperature Specialists

Sintering furnaces are specifically designed to process zirconia. This material is milled in a soft, chalk-like "pre-sintered" state.

The furnace then heats the restoration to extremely high temperatures, typically between 1,400°C and 1,600°C. This process transforms the zirconia, shrinking it to its final size and giving it its exceptional strength and density.

Ceramic Furnaces: The Versatile Workhorses

Ceramic furnaces operate at a lower temperature range and are used for a wider variety of conventional ceramic materials. They are the workhorses for tasks like firing porcelain-fused-to-metal (PFM) crowns or all-ceramic restorations.

These furnaces utilize different heating elements (like Kanthal or Nichrome) suitable for their temperature range and are often where glazing and staining cycles are performed.

Unpacking the Key Functions

While both involve heat, sintering and glazing are fundamentally different processes with different goals.

Sintering: For Strength and Density

Sintering is a transformative process. Its sole purpose is to densify the zirconia framework, turning it from a porous, weak state into a biocompatible and durable final restoration. This is a long cycle, often taking several hours to complete.

Glazing: For Aesthetics and Finish

Glazing is a finishing process. A thin layer of glass-like material is applied to the restoration and then fired at a much lower temperature than sintering.

This creates a lustrous, smooth surface that mimics natural tooth enamel. It also seals any remaining surface porosity, making the restoration more stain-resistant and hygienic.

Understanding the Trade-offs: One Furnace or Two?

The decision between an all-in-one unit and dedicated furnaces comes down to workflow, volume, and budget. Many modern sintering furnaces now include lower-temperature programs for glazing.

The 'All-in-One' Combination Furnace

A single furnace that can handle both high-temperature sintering and lower-temperature glazing offers a clear advantage in saving space and initial cost.

However, this can create a significant bottleneck. A long zirconia sintering cycle can tie up the furnace for hours, preventing technicians from performing shorter glazing or staining cycles on other cases.

Dedicated Sintering and Ceramic Furnaces

Operating separate, dedicated furnaces for sintering and glazing is the standard for high-volume labs. This configuration optimizes workflow and efficiency.

While a long sintering cycle runs in one unit, the ceramic furnace remains free for multiple shorter cycles. This allows for parallel processing, significantly increasing a lab's daily throughput. The downside is the higher initial investment and greater space requirement.

Making the Right Choice for Your Lab

Selecting the right equipment requires matching the furnace's capabilities to your operational needs.

- If your primary focus is high-volume zirconia production: Investing in separate, dedicated sintering and ceramic furnaces will maximize your lab's throughput and efficiency.

- If you are a smaller lab or have a mixed workload: A modern combination furnace that can perform both sintering and glazing may be the most cost-effective and space-efficient solution.

- If your focus is exclusively on pressable or layered ceramics: A dedicated ceramic furnace is all you need, as the high-temperature capabilities of a sintering furnace would be unnecessary.

Ultimately, selecting the right furnace configuration is about aligning your equipment's capabilities with your lab's specific materials and workflow goals.

Summary Table:

| Function | Description | Typical Temperature Range | Key Benefits |

|---|---|---|---|

| Sintering | Densifies zirconia for strength | 1,400°C - 1,600°C | High durability, biocompatibility |

| Glazing | Applies smooth, aesthetic finish | Lower temperatures | Stain resistance, enamel-like surface |

Optimize your dental lab's workflow with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature sintering furnaces, versatile ceramic furnaces, and combination units tailored for zirconia and other materials. Our deep customization ensures precise fit for your unique needs, boosting efficiency and restoration quality. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems can elevate your operations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations