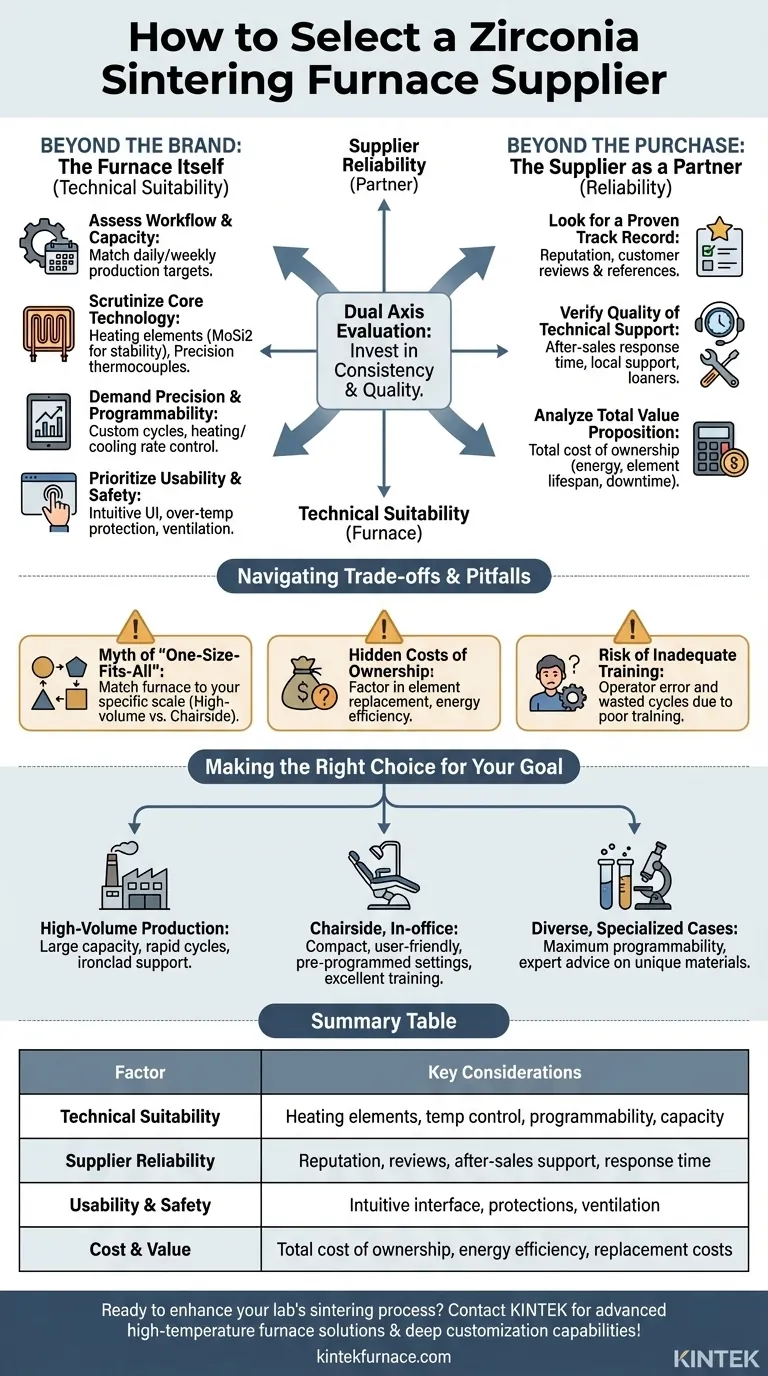

To select a zirconia sintering furnace supplier, you must look beyond the brand name and evaluate them on a dual axis: the technical suitability of the furnace for your specific needs and the supplier's capacity to be a reliable long-term partner. This involves a deep dive into the furnace's core technology, heating precision, and safety features, while also scrutinizing the supplier's reputation, technical support, and after-sales service.

Your choice of a sintering furnace is not just a purchase; it's an investment in the consistency and quality of your final restorations. The best supplier is one whose technology directly matches your clinical or lab workflow and whose support structure minimizes downtime and protects your investment.

Beyond the Brand: Evaluating the Furnace Itself

Before you can assess a supplier, you must first define your technical requirements. The best supplier is irrelevant if their machine doesn't meet your core operational needs.

Assess Your Workflow and Capacity Needs

First, quantify your demand. A high-volume dental lab running multiple shifts has vastly different needs than an in-office practice focused on chairside restorations.

Consider the furnace's processing capacity—how many units can it sinter in a single cycle? Align this with your daily and weekly production targets to avoid creating a bottleneck.

Scrutinize the Core Technology

The reliability of your restorations depends directly on the furnace's internal components. Pay close attention to the heating elements.

Most high-quality furnaces use molybdenum disilicide (MoSi2) elements because they offer excellent stability at the high temperatures required for zirconia. Cheaper alternatives can lead to temperature fluctuations and inconsistent results.

Equally important is the temperature control system. This relies on precise thermocouples to monitor and regulate the heat, ensuring the furnace follows the programmed sintering cycle exactly.

Demand Precision and Programmability

Different types of zirconia require specific heating and cooling profiles. A superior furnace offers fully programmable settings, allowing you to create and save custom cycles for various materials.

Ask about the precision of its heating and cooling rates. The ability to control these variables is critical for achieving the desired translucency, strength, and fit of the final restoration.

Prioritize Usability and Safety

A complex user interface can lead to programming errors, ruined restorations, and wasted time. The furnace should have an intuitive, easy-to-navigate control panel.

Furthermore, verify its safety features. Look for essentials like over-temperature protection, automated ventilation systems, and a robust, well-insulated chamber to minimize heat loss and ensure operator safety.

Evaluating the Supplier as a Long-Term Partner

Once you have a clear picture of your technical needs, you can begin to evaluate suppliers. This part of the process is about gauging reliability, expertise, and support.

Look for a Proven Track Record

A supplier's reputation is a leading indicator of their quality. Look for established companies with years of experience specifically in the dental technology field.

Seek out customer reviews and references from labs or practices similar to yours. A trustworthy supplier will be transparent and willing to connect you with existing clients.

Verify the Quality of Technical Support

This is arguably the most critical factor. When a machine goes down, every hour of downtime costs you money and damages your reputation.

Ask pointed questions about their after-sales support. Is it handled by a local team or a remote call center? What is their guaranteed response time? Do they offer loaner units to keep you operational during repairs?

Analyze the Total Value Proposition

Do not fixate on the initial purchase price alone. A cheaper furnace from a supplier with poor support can become significantly more expensive over its lifetime.

Calculate the total cost of ownership, factoring in energy efficiency, the expected lifespan of heating elements, and the potential cost of downtime. The best value comes from a reliable machine backed by responsive, expert support.

Understanding the Trade-offs and Pitfalls

Making a decision requires being aware of the potential downsides and common mistakes.

The Myth of "One-Size-Fits-All"

A large-capacity furnace designed for industrial lab production will be inefficient and costly for a small practice. Conversely, a small chairside furnace will quickly become a bottleneck in a high-volume environment. Match the furnace to your specific scale.

Hidden Costs of Ownership

The initial investment is only part of the story. Factor in the cost of replacing heating elements, which are consumable components. Inquire about their typical lifespan and replacement cost. Poor energy efficiency can also add significantly to your monthly operational expenses.

The Risk of Inadequate Training

A furnace is only as good as its operator. A supplier who provides poor initial training or inaccessible technical support puts you at risk of user error. Failed sintering cycles due to incorrect programming waste valuable materials, time, and money.

Making the Right Choice for Your Goal

Your final decision should be a balanced assessment of technology and support, tailored to your primary objective.

- If your primary focus is high-volume production: Prioritize a furnace with large capacity, rapid and reliable sintering cycles, and a supplier with an ironclad support agreement that guarantees minimal downtime.

- If your primary focus is chairside, in-office restorations: Choose a compact, user-friendly furnace with pre-programmed settings for common materials and a supplier known for excellent remote and on-site training.

- If your primary focus is handling diverse, specialized cases: Select a furnace with maximum programmability for custom cycles and a supplier whose technical team can provide expert advice on sintering unique or new-to-market materials.

Ultimately, choosing the right supplier is an investment in predictability, ensuring every restoration you produce meets the highest standard of quality.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Technical Suitability | Heating elements (e.g., MoSi2), temperature control, programmability, capacity |

| Supplier Reliability | Reputation, customer reviews, after-sales support, response time |

| Usability & Safety | Intuitive interface, over-temperature protection, ventilation |

| Cost & Value | Total cost of ownership, energy efficiency, element replacement costs |

Ready to enhance your lab's sintering process? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet the unique needs of dental labs, clinics, and research facilities. Contact us today to discuss how our reliable furnaces and expert support can optimize your zirconia sintering for superior results and minimal downtime!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns