Crucially, you must never place greasy or oily metal materials directly into a hot muffle furnace. This practice releases volatile gases that aggressively corrode the furnace's heating elements, drastically shortening their operational lifespan. The correct procedure involves either cleaning the material beforehand or performing a controlled, low-temperature burn-off cycle with proper ventilation.

The core issue is not the grease itself, but the corrosive vapors it releases when heated. Failing to remove these contaminants before high-temperature processing will lead to premature and costly failure of your furnace's heating elements.

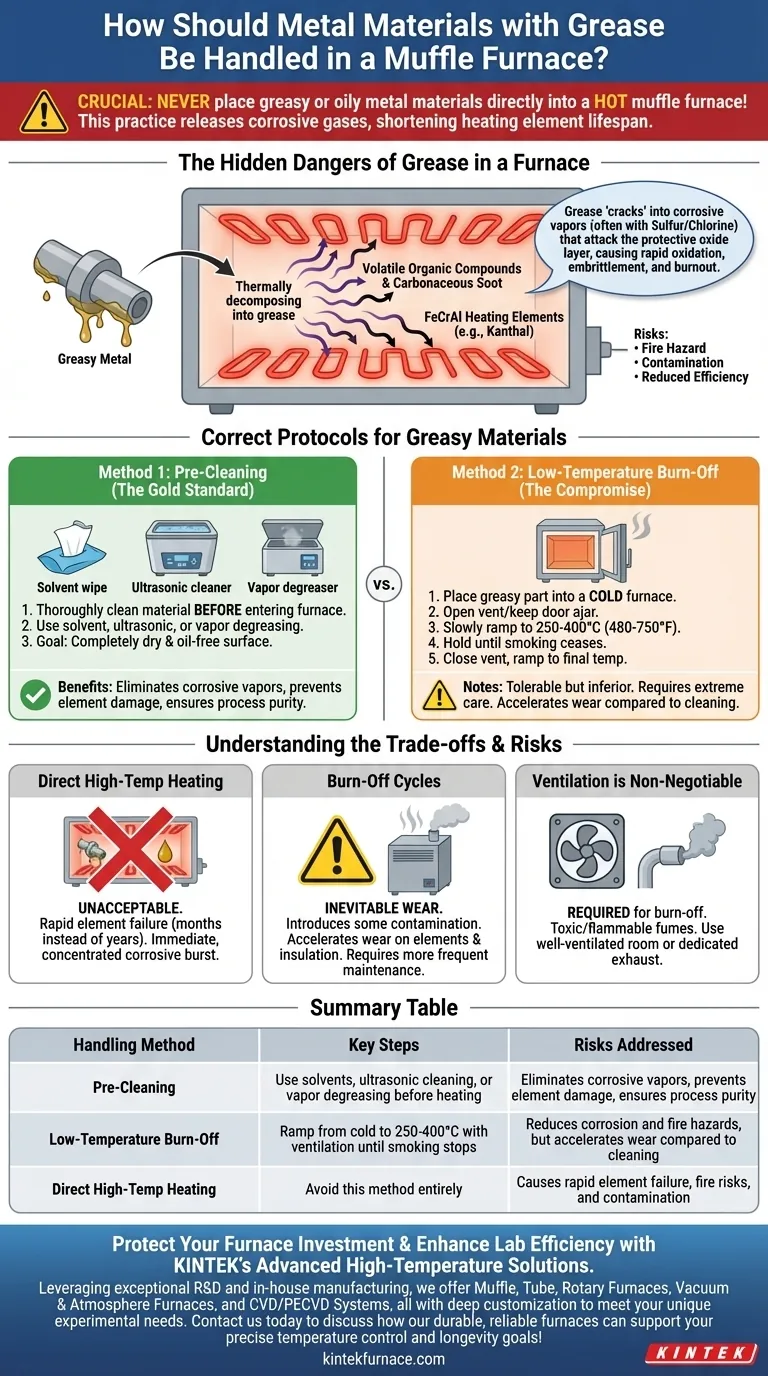

The Hidden Dangers of Grease in a Furnace

When you heat a metal part, your goal is to alter its properties, not to destroy your equipment. Introducing hydrocarbon-based contaminants like grease or oil fundamentally changes the chemical environment inside the furnace, creating significant risks.

Why Grease is So Damaging

Grease and cutting oils are complex hydrocarbons. At elevated temperatures, they don't just evaporate; they thermally decompose, or "crack," into a mixture of volatile organic compounds and carbonaceous soot.

These volatile gases fill the furnace chamber. If the contaminants contain sulfur or chlorine, which is common in many industrial lubricants, the resulting vapors become highly corrosive.

The Attack on Heating Elements

Most muffle furnace heating elements are made from alloys like iron-chromium-aluminum (FeCrAl), often known by the trade name Kanthal. These elements rely on a stable, protective layer of aluminum oxide to withstand extreme temperatures.

The hot, carbon-rich, and potentially acidic atmosphere created by burning grease attacks this protective oxide layer. This leads to rapid oxidation, embrittlement, and burnout, causing the elements to fail months or even years ahead of schedule.

The Risk of Fire and Contamination

Beyond corrosion, there are two other primary risks. First, if oil is introduced into a furnace already above its flash point, the vapors can ignite, creating a fire hazard.

Second, the incomplete combustion of grease leaves behind a layer of soot (carbon). This soot can contaminate your workpiece, interfering with metallurgical processes, and coat the furnace's insulation, reducing its efficiency.

Correct Protocols for Greasy Materials

Protecting your furnace requires a strict protocol. The choice is between removing the contaminant before heating or carefully managing its removal inside the furnace at low temperatures.

Method 1: Pre-Cleaning (The Gold Standard)

The safest and most effective method is to thoroughly clean the material before it enters the furnace. This completely eliminates the risk of generating corrosive volatiles.

Effective cleaning methods include solvent wiping, ultrasonic cleaning with appropriate detergents, or vapor degreasing. The goal is a completely dry and oil-free surface.

Method 2: Low-Temperature Burn-Off (The Compromise)

If pre-cleaning is not feasible, a controlled burn-off is a tolerable but inferior alternative. This must be done with extreme care to minimize damage.

Place the greasy part into a cold furnace. With the furnace vent open or the door slightly ajar to allow fumes to escape, slowly ramp the temperature to a point just above the smoke point of the oil, typically 250-400°C (480-750°F).

Hold at this temperature until all smoking has ceased. Only then should you close the vent and begin your ramp to the final, high-process temperature.

Understanding the Trade-offs

Choosing a method involves balancing process purity, equipment longevity, and operational speed. This is a decision with significant financial and operational consequences.

Why Direct High-Temperature Heating is Unacceptable

Placing an oily part directly into a hot furnace is an act of negligence. The intense, immediate vaporization creates a concentrated burst of corrosive gases that will cause maximum damage to the heating elements. This can reduce the lifespan of a set of elements from over a year to just a few months.

The Inevitable Wear from Burn-Off Cycles

Even a controlled, low-temperature burn-off introduces some level of contamination and corrosive atmosphere into the chamber. While far better than the direct method, it will still accelerate wear and tear on the elements and insulation compared to heating only clean parts. Furnaces used for burn-offs require more frequent maintenance.

Ventilation is Non-Negotiable

The fumes generated from burning oil are often toxic and flammable. Performing a burn-off cycle requires a well-ventilated room and, ideally, a furnace equipped with a dedicated exhaust port that can be ducted fatores outside. Never perform this process in an enclosed space.

Making the Right Choice for Your Goal

Your standard operating procedure should be dictated by your primary objective and the resources available to you.

- If your primary focus is equipment longevity and process purity: Always pre-clean your materials thoroughly before they enter the furnace.

- If your primary focus is expediency and pre-cleaning is not an option: Use a controlled, low-temperature burn-off cycle in a vented furnace, and plan for increased maintenance costs.

- If you are ashing a sample to determine organic content: The burn-off cycle is your process, but you must use a furnace designed for this purpose, with protected elements and robust ventilation.

Ultimately, treating your furnace with care by controlling what you put inside it is the only way to ensure its accuracy, reliability, and long-term value.

Summary Table:

| Handling Method | Key Steps | Risks Addressed |

|---|---|---|

| Pre-Cleaning | Use solvents, ultrasonic cleaning, or vapor degreasing before heating | Eliminates corrosive vapors, prevents element damage, ensures process purity |

| Low-Temperature Burn-Off | Ramp from cold to 250-400°C with ventilation until smoking stops | Reduces corrosion and fire hazards, but accelerates wear compared to cleaning |

| Direct High-Temp Heating | Avoid this method entirely | Causes rapid element failure, fire risks, and contamination |

Protect your furnace investment and enhance lab efficiency with KINTEK's advanced high-temperature solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our durable, reliable furnaces can support your precise temperature control and longevity goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals