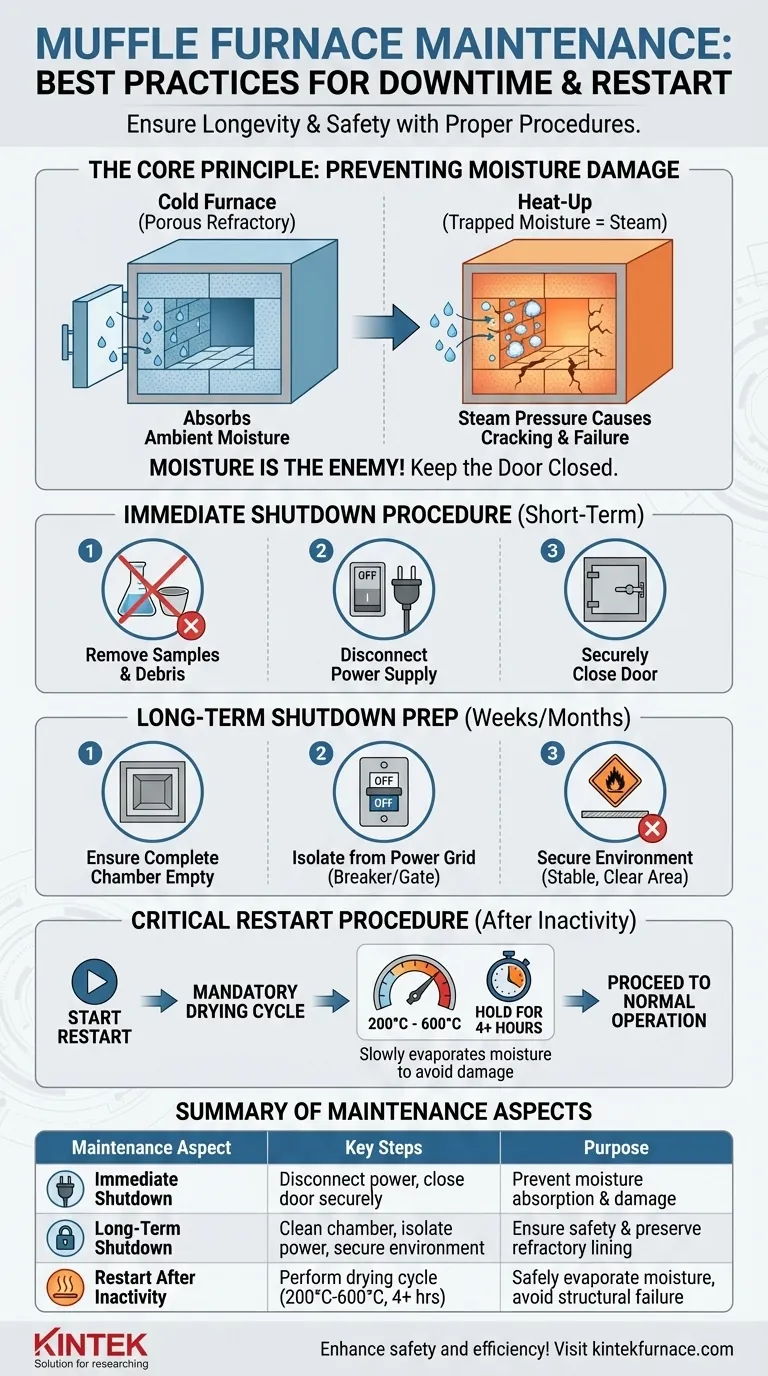

Properly maintaining a muffle furnace when it is not in use is a simple but critical task. The most important steps are to disconnect the power supply and keep the furnace door securely closed. This prevents ambient moisture from infiltrating and damaging the porous refractory materials that line the furnace interior, which is the primary cause of degradation during periods of inactivity.

The core principle of furnace maintenance during downtime is moisture prevention. Protecting the internal refractory lining from moisture absorption not only preserves the furnace but is also essential for safe and effective operation upon restart, which requires a specific drying cycle after any long-term shutdown.

The Core Principle: Protecting the Refractory Lining

A muffle furnace's longevity is directly tied to the condition of its internal refractory brick or fiber insulation. This material is highly effective at handling extreme heat but is vulnerable when the furnace is cold.

Why Moisture is the Enemy

Refractory materials are porous by nature. When left open to the atmosphere, they act like a sponge, slowly absorbing humidity from the air.

This absorbed moisture becomes a significant problem during the next heat-up. As the furnace temperature rises, the trapped water turns into steam, creating immense internal pressure within the refractory material, which can lead to cracking, spalling, and premature failure of the insulation.

The Immediate Shutdown Procedure

For any period of non-use, whether overnight or for a weekend, the procedure is straightforward.

First, ensure all samples have been removed from the chamber. Then, turn off the main power switch and completely disconnect the furnace from its power source using its dedicated breaker or gate. Finally, securely close the furnace door and ensure it is latched.

Preparing for a Long-Term Shutdown

If you anticipate the furnace will be inactive for several weeks or months, a few extra steps ensure its integrity and safety.

Ensuring a Clean and Empty Chamber

Before storage, verify the furnace chamber is completely empty. Removing any forgotten crucibles, samples, or debris prevents potential contamination or reactions during future use.

Complete Electrical Disconnection

For extended shutdowns, relying on the furnace's power switch is insufficient. Use the dedicated electrical gate or circuit breaker to completely isolate the unit from the power grid. This eliminates any risk from power surges and prevents accidental activation.

Securing the Environment

Confirm the furnace is on stable, level ground and that the surrounding area is clear of all flammable or explosive materials. This is a fundamental safety practice that should be maintained even when the furnace is not operational.

The Critical Restart Procedure After Inactivity

Restarting a furnace that has been shut down for a long period is the moment when damage from moisture is most likely to occur. A specific warm-up procedure is not optional; it is essential.

The Necessity of a Drying Cycle

You must assume that a furnace stored for an extended time has absorbed some amount of moisture, regardless of precautions. Attempting a rapid heat-up to a high operating temperature will almost certainly damage the refractory lining.

A slow, controlled drying or "baking out" cycle is required to gently drive off this moisture as vapor before it can turn to high-pressure steam.

Step-by-Step Drying Protocol

For a standard muffle furnace that has been inactive for a long term, a drying cycle is mandatory.

Set the furnace to a low temperature, typically between 200°C and 600°C, and hold it in this range for at least four hours. This allows trapped moisture to evaporate slowly and safely exit the refractory pores without causing structural damage. After this cycle is complete, you can proceed with normal operation.

Making the Right Choice for Your Goal

Your maintenance procedure should adapt to your operational timeline to ensure safety and equipment longevity.

- If your primary focus is short-term shutdown (overnight or a weekend): Ensure the furnace is empty, disconnect the power, and securely close the door to minimize moisture ingress.

- If your primary focus is restarting after a long-term shutdown (weeks or months): You must perform a mandatory drying cycle at 200°C-600°C for several hours before attempting to reach your target operating temperature.

- If your primary focus is overall lab safety: Always ensure the furnace has a dedicated, properly grounded circuit and that a fire extinguisher is nearby, regardless of whether the unit is in use or in storage.

Following these disciplined procedures ensures your furnace remains a safe, reliable, and long-lasting asset in your laboratory.

Summary Table:

| Maintenance Aspect | Key Steps | Purpose |

|---|---|---|

| Immediate Shutdown | Disconnect power, close door securely | Prevent moisture absorption and damage |

| Long-Term Shutdown | Clean chamber, isolate power, secure environment | Ensure safety and preserve refractory lining |

| Restart After Inactivity | Perform drying cycle at 200°C-600°C for 4+ hours | Safely evaporate moisture to avoid damage |

Ensure your laboratory's high-temperature furnaces, like muffle, tube, or vacuum models, are maintained for peak performance and longevity. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions with deep customization for diverse labs. Contact us today to discuss how our tailored furnace systems can meet your unique experimental needs and enhance safety and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis