In metal material research, the box type annealing atmosphere furnace serves as a precision instrument for controlled heat treatment. It allows researchers to systematically manipulate a material's properties by precisely managing temperature, time, and the surrounding atmosphere, enabling the study of processes like aging strengthening in new aluminum alloys or the optimization of high-performance metals like titanium.

The true value of an atmosphere furnace in research is not merely heating a material, but creating a highly controlled and repeatable environment. This allows scientists to isolate variables and definitively link specific heat treatment parameters to changes in a material's microstructure and performance.

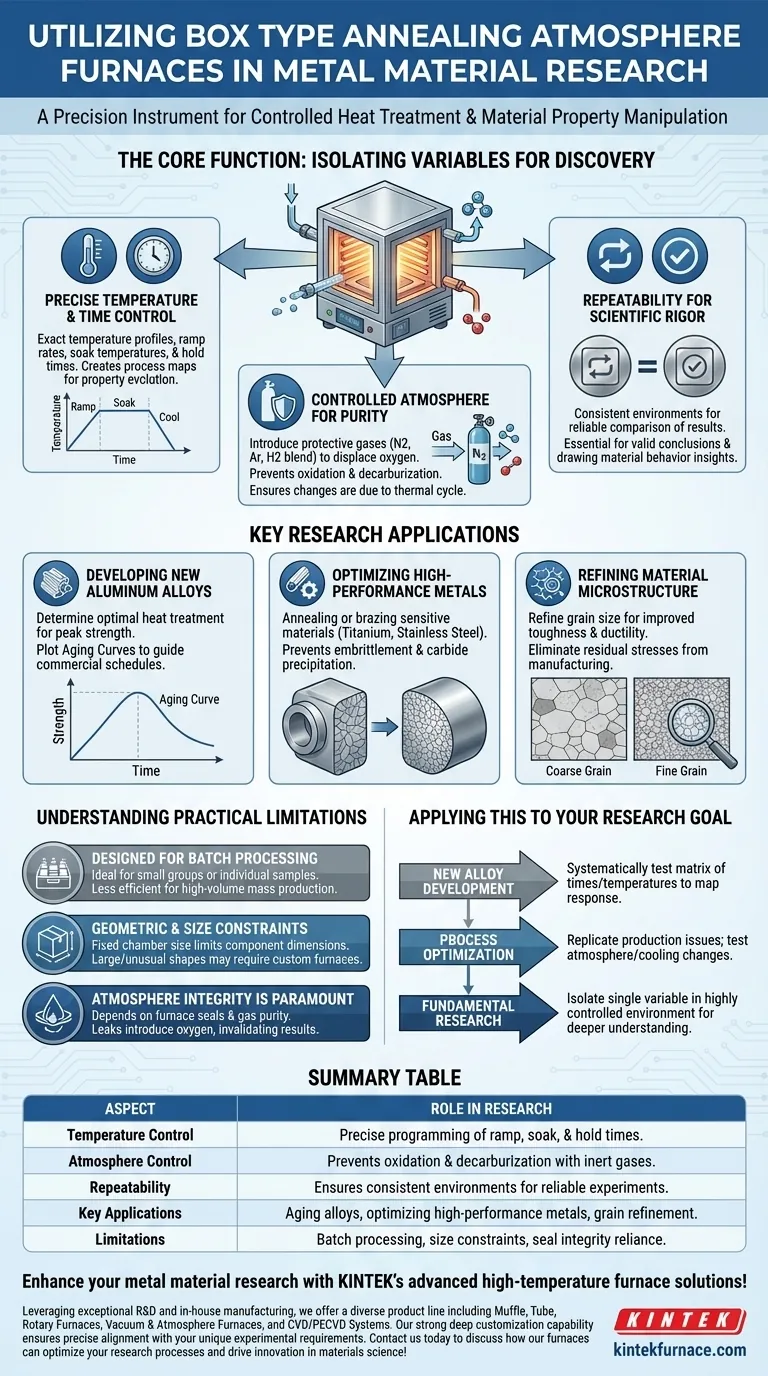

The Core Function: Isolating Variables for Discovery

A box type atmosphere furnace is foundational to materials science because it provides an experimental environment where variables can be independently controlled. This scientific rigor is essential for developing and understanding materials.

Precise Temperature and Time Control

Researchers can program exact temperature profiles, including ramp rates, soak temperatures, and hold times. For example, studying the aging strengthening of an aluminum alloy involves holding samples at a precise temperature, like 180°C, for varying durations.

This control allows for the creation of a "process map," showing how a material's hardness or strength evolves over time at a specific temperature.

A Controlled Atmosphere for Purity

The "atmosphere" function is critical for preventing unwanted chemical reactions. Introducing a protective or reducing atmosphere (like nitrogen, argon, or a hydrogen blend) displaces oxygen.

This prevents oxidation and decarburization, ensuring that any observed changes in the material are a direct result of the thermal cycle, not contamination from the air. This is crucial for reactive metals or for studying subtle microstructural changes.

Repeatability for Scientific Rigor

For research to be valid, experiments must be repeatable. An atmosphere furnace provides a consistent environment, ensuring that a sample tested today and a sample tested next month undergo the exact same process.

This repeatability is non-negotiable for comparing results and drawing reliable conclusions about material behavior.

Key Research Applications

The furnace's ability to control these core variables makes it indispensable for a range of research activities, from developing new alloys to optimizing existing ones.

Developing New Aluminum Alloys

The provided example of aging aluminum alloys is a classic application. Researchers use the furnace to determine the optimal heat treatment for achieving peak strength.

By testing samples after different time intervals, they can plot an aging curve that guides the development of commercial heat treatment schedules for new high-performance alloys.

Optimizing High-Performance Metals

Materials like titanium alloys and stainless steel require extremely pure environments during heat treatment. The furnace is used for annealing (softening and stress-relieving) or brazing these sensitive materials.

Precise control prevents oxygen embrittlement in titanium or carbide precipitation in stainless steel, ensuring the final component has the desired mechanical properties and corrosion resistance.

Refining Material Microstructure

Beyond creating new alloys, the furnace is used for fundamental studies on material structure. Annealing can be used to refine grain size, which improves a material's toughness and ductility.

It is also used to eliminate residual stresses induced by manufacturing processes like forging or welding, which prevents premature failure and improves the material's service life.

Understanding the Practical Limitations

While powerful, the box type atmosphere furnace is not a universal solution. Understanding its limitations is key to proper application.

Designed for Batch Processing

These furnaces operate on a batch-by-batch basis. This is ideal for a research setting where individual samples or small groups of components are tested under specific conditions.

However, this makes it less efficient for high-volume mass production, where continuous-belt furnaces are often preferred.

Geometric and Size Constraints

As the name implies, a "box" furnace has a fixed internal chamber size. This limits the dimensions of the components that can be treated. Very large or unusually shaped parts may require custom-built or different types of furnaces.

Atmosphere Integrity is Paramount

The effectiveness of the controlled atmosphere depends entirely on the integrity of the furnace seals and the purity of the gas supply. Even a small leak can introduce oxygen and compromise an entire experiment, invalidating the results.

Applying This to Your Research Goal

To effectively utilize a box type annealing furnace, align your experimental approach with your primary objective.

- If your primary focus is new alloy development: Use the furnace to systematically test a matrix of different times and temperatures to map out the material's response and identify optimal processing windows.

- If your primary focus is process optimization: Use the furnace to replicate production issues on a small scale, testing how changes in atmosphere or cooling rate can improve final properties or prevent defects.

- If your primary focus is fundamental research: Use the highly controlled environment to isolate a single variable, such as the effect of trace oxygen on a specific phase transformation, to gain deeper scientific understanding.

Ultimately, this furnace is a powerful tool that transforms the art of heat treatment into a precise and repeatable science.

Summary Table:

| Aspect | Role in Research |

|---|---|

| Temperature Control | Enables precise programming of ramp rates, soak temperatures, and hold times for material property manipulation. |

| Atmosphere Control | Uses gases like nitrogen or argon to prevent oxidation and decarburization, ensuring pure experimental conditions. |

| Repeatability | Provides consistent environments for reliable, repeatable experiments and valid scientific conclusions. |

| Key Applications | Includes aging strengthening in aluminum alloys, optimization of titanium and stainless steel, and grain refinement. |

| Limitations | Batch processing only, size constraints, and reliance on seal integrity for atmosphere purity. |

Enhance your metal material research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, helping you achieve superior heat treatment outcomes. Contact us today to discuss how our furnaces can optimize your research processes and drive innovation in materials science!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity