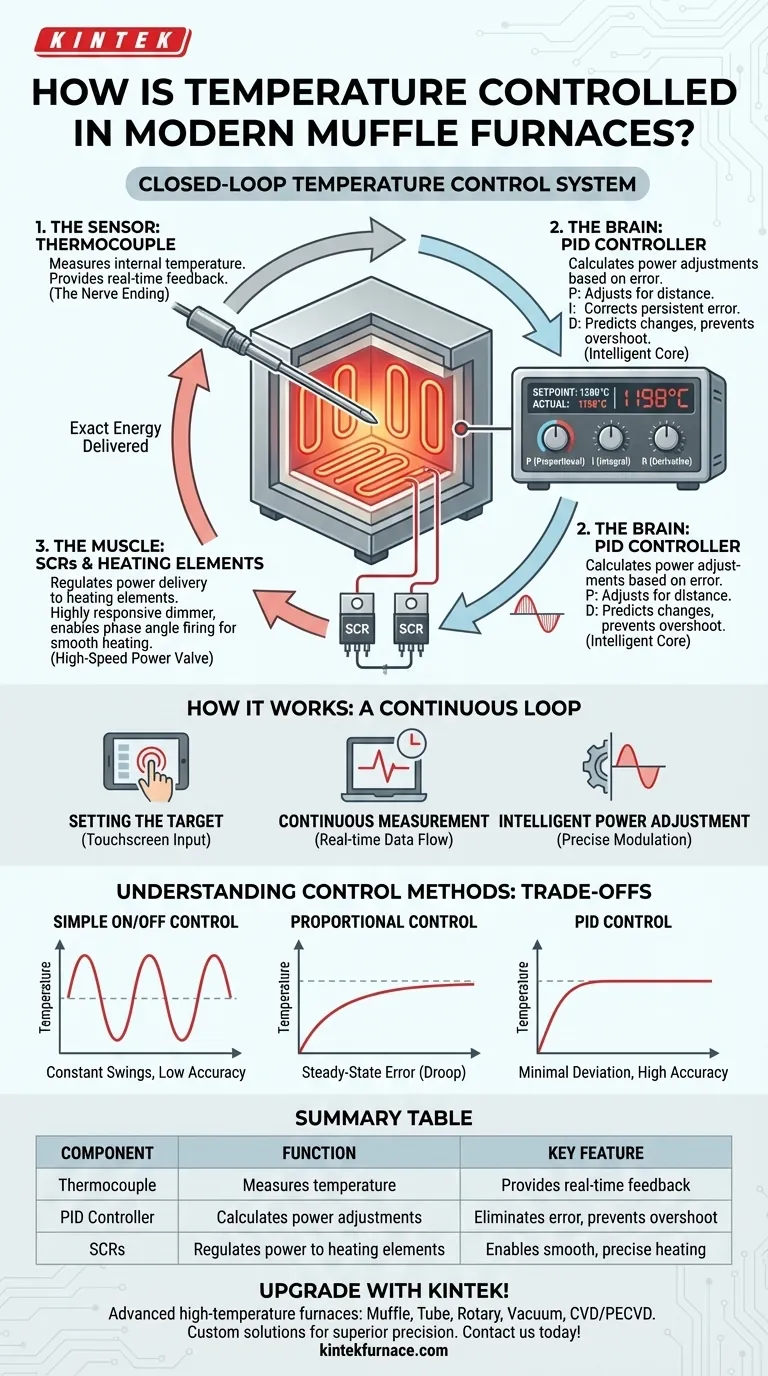

At its core, temperature in a modern muffle furnace is controlled by a closed-loop system featuring three critical components. A sensor, typically a thermocouple, measures the internal temperature and sends this data to a digital PID controller. This controller, acting as the system's brain, then calculates the precise amount of power needed and instructs Silicon Controlled Rectifiers (SCRs) to deliver that exact energy to the electric heating elements, ensuring stable and accurate heat.

The key to modern furnace precision is not a single component, but the dynamic interaction within a digital feedback loop. This system constantly measures, calculates, and corrects to hold a temperature setpoint with remarkable stability, far surpassing older control methods.

The Core Components of Temperature Control

A modern muffle furnace's temperature control is an elegant synthesis of a sensor, a controller, and a power regulator working in unison. Understanding each part clarifies how the entire system achieves such high precision.

The Sensor: The Thermocouple

The thermocouple is the system's nerve ending. It is a robust sensor placed inside the furnace chamber to get a real-time reading of the actual temperature.

This continuous stream of data is the essential feedback that makes automated control possible. Without an accurate sensor, the controller is blind.

The Brain: The PID Controller

The PID (Proportional-Integral-Derivative) controller is the intelligent core of the system. It receives the temperature data from the thermocouple and compares it to the desired temperature you have programmed (the setpoint).

It then performs a sophisticated calculation to decide how to adjust the heating:

- Proportional: Adjusts power based on how far the current temperature is from the setpoint.

- Integral: Corrects for small, persistent errors to ensure the furnace doesn't settle slightly above or below the target.

- Derivative: Predicts future temperature changes to prevent overshooting the target and dampen oscillations.

The Muscle: SCRs and Heating Elements

Silicon Controlled Rectifiers (SCRs) act as a high-speed, solid-state power valve. Based on instructions from the PID controller, the SCRs precisely modulate the flow of electricity to the heating elements.

Think of them not as a simple on/off switch, but as a highly responsive dimmer. They can deliver power in fine increments, a method often called phase angle firing, which allows for exceptionally smooth and stable heating.

How These Components Work Together

The process is a continuous, high-speed loop designed to maintain thermal equilibrium with minimal deviation.

Setting the Target

An operator uses a digital interface, often a touchscreen, to input a target temperature or a complex, time-based heating profile. Modern furnaces can store multi-step programs with different ramps and soaks.

Continuous Measurement and Correction

Once running, the thermocouple constantly reports the chamber temperature to the PID controller, thousands of times per minute.

The controller instantly calculates the "error"—the difference between the actual temperature and the setpoint.

Intelligent Power Adjustment

The PID algorithm uses this error value to command the SCRs, which adjust power to the heating elements. If the furnace is too cool, power is increased. As it approaches the setpoint, power is progressively reduced to avoid overshooting.

This closed-loop system is incredibly responsive, quickly compensating for any fluctuation, such as heat loss from opening the furnace door.

Understanding the Trade-offs: Control Methods

PID has become the industry standard for a clear reason: it outperforms simpler methods in both accuracy and efficiency.

Simple On/Off (Thermostatic) Control

This is the most basic method, like a home thermostat. The heater is fully on until the setpoint is reached, then fully off. This leads to constant temperature swings above and below the target, which is unacceptable for precise applications.

Proportional Control

A step up, proportional control reduces power as the temperature nears the setpoint. This prevents major overshooting but often results in the furnace stabilizing at a temperature slightly different from the target, a phenomenon known as "droop" or steady-state error.

The Superiority of PID Control

PID control solves the problems of both simpler methods. The "Integral" function eliminates the steady-state error of proportional control, while the "Derivative" function actively prevents the overshooting seen in on/off systems. This makes it the most accurate and energy-efficient choice.

Making the Right Choice for Your Application

Understanding the control system allows you to select a furnace that aligns with your technical requirements.

- If your primary focus is process repeatability and accuracy (e.g., materials science, quality control): You must ensure the furnace uses a true PID controller, as this is the only way to guarantee minimal temperature deviation.

- If your primary focus is running complex thermal profiles (e.g., annealing, ashing, tempering): Look for a furnace with advanced multi-segment programming capabilities to automate complex heating and cooling cycles.

- If your primary focus is operational efficiency and ease of use: Prioritize models with energy-saving hold settings, intuitive touchscreen interfaces, and remote monitoring capabilities.

By understanding how these systems work, you can ensure your thermal processing is not a variable, but a precisely controlled constant.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Thermocouple | Measures temperature | Provides real-time feedback |

| PID Controller | Calculates power adjustments | Eliminates error and prevents overshoot |

| SCRs | Regulates power to heating elements | Enables smooth, precise heating |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures solutions tailored to your unique experimental needs for superior temperature control and efficiency. Contact us today to discuss how we can enhance your thermal processing!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating