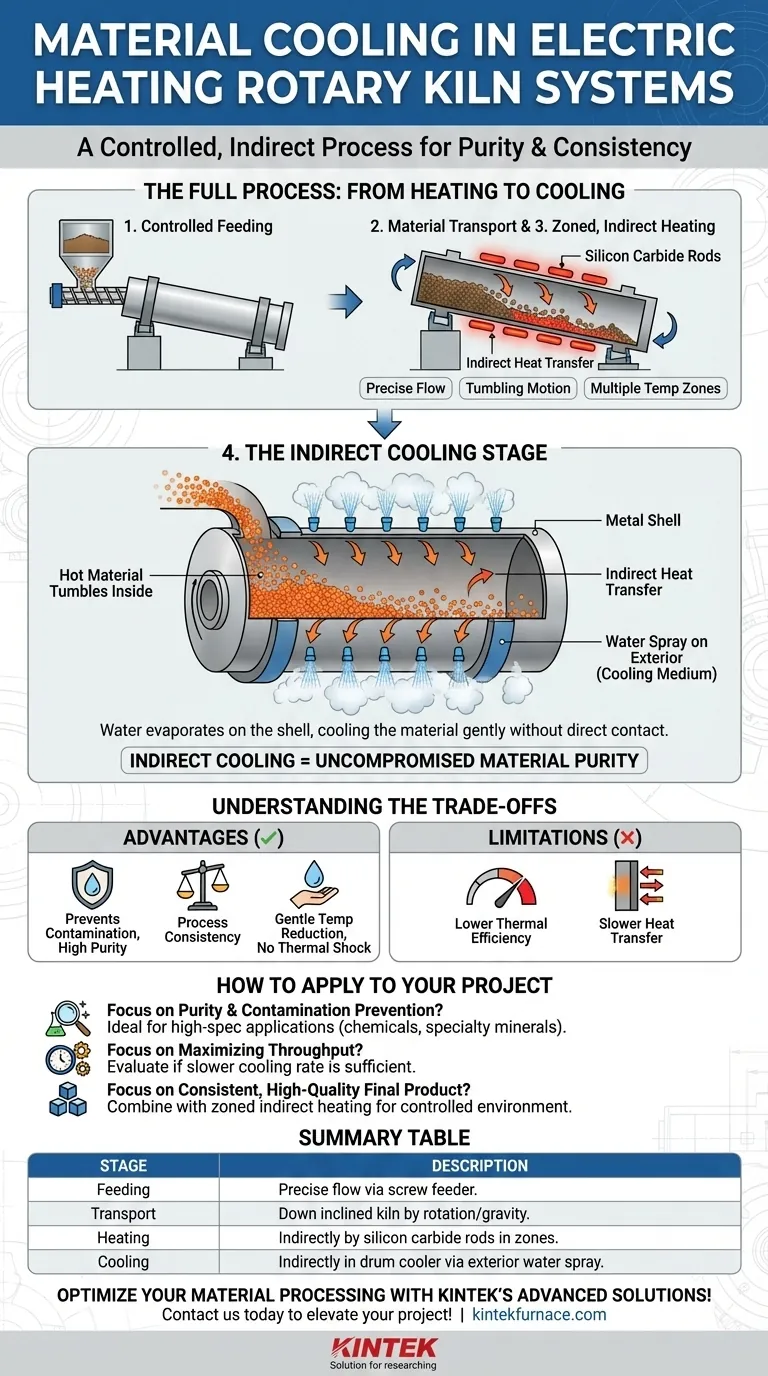

In an electric heating rotary kiln, the material is cooled indirectly after discharge using a dedicated drum cooler. This unit, separate from the main heating kiln, sprays water onto the exterior of its rotating shell. The hot material tumbles inside, transferring its heat through the metal wall to the water, which then evaporates, bringing the material down to the required temperature without any direct contact with the cooling medium.

The cooling mechanism in an electric rotary kiln is not an isolated feature but a final, crucial step in a system designed for controlled, indirect material processing. The choice of indirect cooling mirrors the indirect heating method, prioritizing material purity and consistency over raw speed.

The Full Process: From Heating to Cooling

To understand the cooling stage, it's essential to view it as the final step in a continuous, controlled journey the material takes through the entire kiln system.

H3: Controlled Feeding

The process begins with a feeding system, often a single or double screw feeder. This component's role is to deliver a precise, quantitative flow of material into the kiln, ensuring a consistent load for the heating process.

H3: Material Transport

The material enters the high end of the inclined kiln body. As the kiln rotates, the material tumbles and gradually moves downward toward the discharge end due to gravity and the drum's slope. This controlled movement ensures every particle has a predictable residence time in each zone.

H3: Zoned, Indirect Heating

As the material travels, it passes through multiple temperature control zones. The heating elements, typically silicon carbide rods, are located at the bottom of the kiln, outside the main material path.

Heat is transferred indirectly through the kiln's shell to the material tumbling inside. This method prevents contamination and allows for extremely precise temperature management across the different heating stages.

H3: The Indirect Cooling Stage

Once the material exits the main heating kiln, it enters the drum cooler. Here, the principle of indirect heat transfer is repeated, but in reverse.

Water is sprayed on the outside of the cooler's rotating shell. The hot material on the inside transfers its thermal energy through the shell wall, causing the external water to turn to steam. This cools the material gently and without introducing moisture or other contaminants.

Understanding the Trade-offs

The choice of an indirect cooling system is a deliberate engineering decision with specific advantages and limitations that are critical to understand.

H3: Advantage: Uncompromised Material Purity

The primary benefit of indirect cooling is preventing contamination. Because the cooling medium (water) never touches the product, the material's chemical and physical purity is preserved. This is essential for high-spec applications in chemicals, catalysts, and specialty minerals.

H3: Advantage: Process Consistency

This method provides a gentle, controlled reduction in temperature, which can be crucial for preventing thermal shock in sensitive materials. It completes the highly controlled, indirect process started in the heating chamber.

H3: Limitation: Lower Thermal Efficiency

Indirect cooling is less thermally efficient than direct methods, such as quenching the material with a water spray. Heat must first conduct through the thick steel wall of the cooler, a slower process that can limit the overall throughput of the system.

How to Apply This to Your Project

Your specific processing goals will determine if the characteristics of this cooling system align with your needs.

- If your primary focus is material purity and preventing contamination: The indirect drum cooler is the ideal solution, as it completely isolates your product from the cooling medium.

- If your primary focus is maximizing throughput: You must evaluate if the cooling rate of an indirect system is sufficient for your production targets, as it is inherently slower than direct quenching.

- If your primary focus is creating a consistent, high-quality final product: The combination of zoned indirect heating and gentle indirect cooling provides an exceptionally controlled environment from start to finish.

Ultimately, viewing the cooling system as an integral part of the kiln's entire controlled processing path is the key to leveraging this technology effectively.

Summary Table:

| Stage | Description |

|---|---|

| Feeding | Material enters via screw feeder for precise flow control. |

| Transport | Material moves down inclined kiln via rotation and gravity. |

| Heating | Indirect heating with silicon carbide rods in multiple zones. |

| Cooling | Indirect cooling in drum cooler with water spray on shell exterior. |

Optimize your material processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs for enhanced purity, efficiency, and consistency. Contact us today to discuss how we can elevate your project!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency