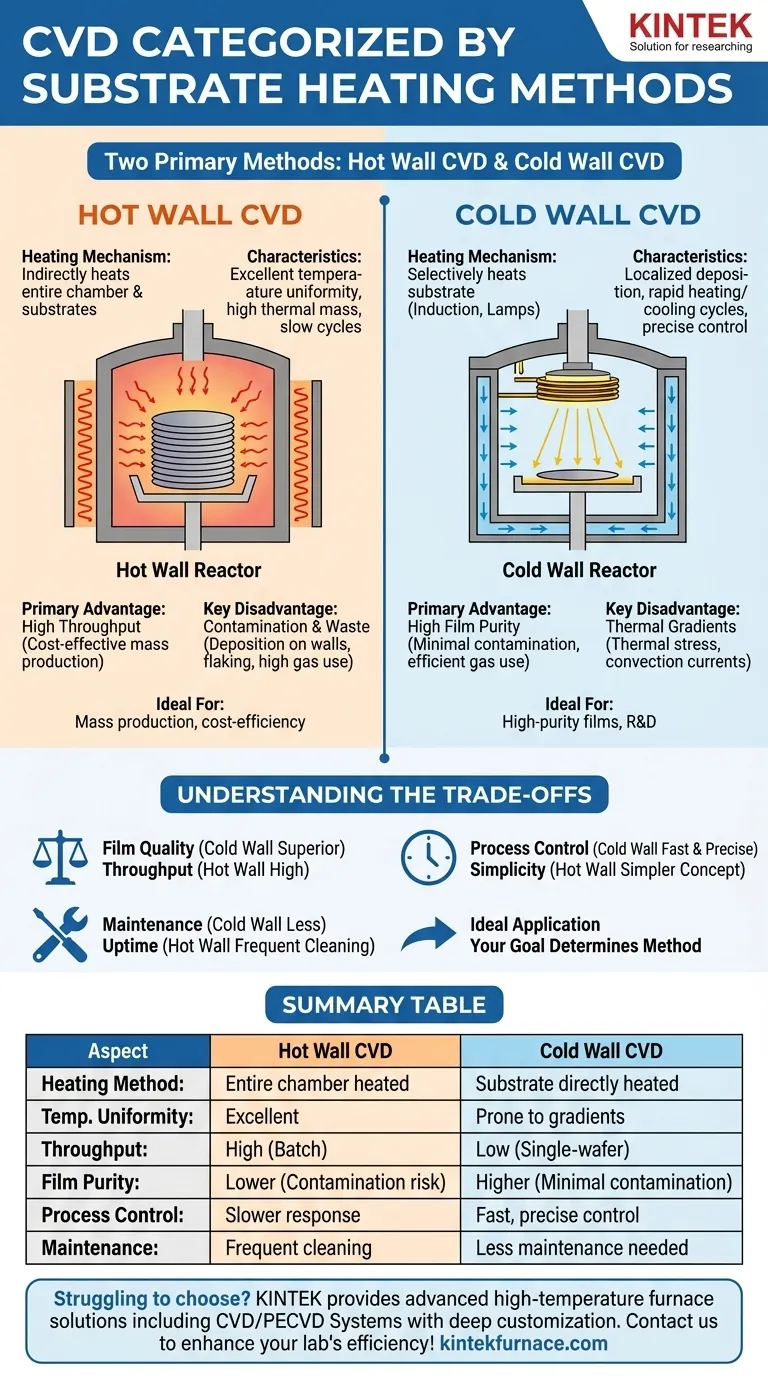

In Chemical Vapor Deposition (CVD), the process is broadly categorized by how the substrate is heated. The two primary methods are Hot Wall CVD, where the entire reaction chamber is heated, and Cold Wall CVD, where only the substrate is directly and selectively heated while the chamber walls remain cool. This fundamental design choice dictates the system's performance, applications, and limitations.

The distinction between Hot Wall and Cold Wall CVD is a critical engineering trade-off. Hot Wall systems are built for high-throughput batch processing and temperature uniformity, while Cold Wall systems are engineered for high-purity, single-wafer deposition with precise process control.

The Hot Wall CVD Reactor: Emphasizing Uniformity

In a Hot Wall reactor, the entire process chamber is placed inside a furnace, typically a resistive or tube furnace. This design heats the chamber walls and the substrates simultaneously to a uniform temperature.

The Heating Mechanism

The substrates are heated indirectly. Heat from the external furnace radiates from the hot chamber walls to the substrates. This creates an environment with a very low thermal gradient across the entire reaction zone.

Process Characteristics

Hot Wall systems are defined by their excellent temperature uniformity, which allows for the simultaneous processing of many substrates (wafers) in a single batch. However, they have significant thermal mass, meaning they heat up and cool down very slowly.

Primary Advantage: High Throughput

The ability to process a large batch of wafers at once makes Hot Wall CVD exceptionally cost-effective for mass production. This high throughput is its defining benefit, making it a workhorse for applications where volume is paramount.

Key Disadvantage: Contamination and Waste

Because the entire chamber is hot, deposition occurs on the chamber walls just as it does on the substrates. Over time, this unwanted film flakes off, creating particles that can contaminate the wafers. This also wastes expensive precursor gases and necessitates frequent, time-consuming maintenance cycles.

The Cold Wall CVD Reactor: Focusing on Purity

In a Cold Wall reactor, the heating is targeted directly at the substrate or the substrate holder (susceptor). The chamber walls are kept at or near room temperature, often with active water-cooling.

The Heating Mechanism

Heating is achieved selectively using methods like induction heating of a graphite susceptor or high-intensity lamps shining through a quartz window onto the substrate. This creates a large temperature difference between the hot substrate and the cool chamber walls.

Process Characteristics

Deposition is highly localized to the hot substrate surface. This allows for rapid heating and cooling cycles, giving engineers precise control over the process. This method is typically used for single-wafer processing.

Primary Advantage: High Film Purity

Since deposition does not occur on the cool chamber walls, the risk of particle contamination from flaking is virtually eliminated. This results in higher-purity films and makes more efficient use of precursor gases. This is critical for fabricating high-performance semiconductor devices.

Key Disadvantage: Thermal Gradients

The steep temperature gradient between the substrate and the chamber walls can induce thermal stress in the substrate. It can also create complex gas-phase convection currents above the substrate, which can affect film uniformity if not properly managed.

Understanding the Trade-offs: Hot Wall vs. Cold Wall

Choosing between these two methods involves a clear set of engineering compromises that directly impact the final product and process economics.

Film Quality vs. Throughput

Cold Wall reactors produce superior, high-purity films suitable for advanced microelectronics. Hot Wall reactors deliver high throughput for applications where minor particulate contamination is tolerable, such as some solar cells or protective coatings.

Process Control vs. Simplicity

Cold Wall systems offer fast, precise control over temperature, enabling rapid process changes and advanced material growth. Hot Wall systems are simpler in concept but their large thermal inertia makes them slow to respond and unsuitable for rapid prototyping.

Maintenance and Uptime

Cold Wall reactors require significantly less cleaning, leading to higher equipment uptime. Hot Wall reactors demand frequent and intensive cleaning to remove wall deposits, which translates to more downtime and higher operational costs.

Making the Right Choice for Your Application

Your specific application goals will determine which heating method is appropriate.

- If your primary focus is mass production and cost-efficiency: A Hot Wall reactor is the logical choice for its unparalleled batch processing capability.

- If your primary focus is high-purity films for advanced devices: A Cold Wall reactor is the definitive choice for minimizing contamination and achieving superior material quality.

- If your primary focus is research and development (R&D): The rapid cycling and process flexibility of a Cold Wall system make it ideal for experimenting with new materials and deposition parameters.

Ultimately, understanding the heating mechanism is key to selecting a CVD system that aligns with your specific goals for film quality, throughput, and cost.

Summary Table:

| Aspect | Hot Wall CVD | Cold Wall CVD |

|---|---|---|

| Heating Method | Entire chamber heated via furnace | Substrate directly heated (e.g., induction, lamps) |

| Temperature Uniformity | Excellent | Prone to thermal gradients |

| Throughput | High (batch processing) | Low (single-wafer processing) |

| Film Purity | Lower (risk of contamination) | Higher (minimal contamination) |

| Process Control | Slower response | Fast, precise control |

| Maintenance | Frequent cleaning required | Less maintenance needed |

| Ideal For | Mass production, cost-efficiency | High-purity films, R&D |

Struggling to choose the right CVD system for your lab's unique needs? At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your specific requirements. Leveraging our exceptional R&D and in-house manufacturing capabilities, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization expertise ensures we can design a solution that precisely matches your experimental goals, whether you prioritize high throughput with Hot Wall systems or high purity with Cold Wall setups. Don't let equipment limitations hold back your research or production—contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does a PECVD system contribute to (n)poly-Si layers? High-Throughput In-Situ Doping Explained

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What are the technical advantages of using a CVD system? Optimize Carbon Nanotube Growth for Thermal Conductivity

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis