At its core, an atmosphere box furnace is used to execute critical heat treatment processes like quenching, annealing, and tempering on metal materials. It achieves this by heating the parts within a tightly sealed chamber where the gaseous environment is precisely controlled, preventing unwanted reactions and ensuring the material's final properties are exactly as intended.

The crucial takeaway is not just that the furnace heats metal, but that it controls the atmosphere surrounding the metal. This control is the key to preventing destructive reactions like oxidation at high temperatures and enabling specific, repeatable changes to a material's microstructure and surface.

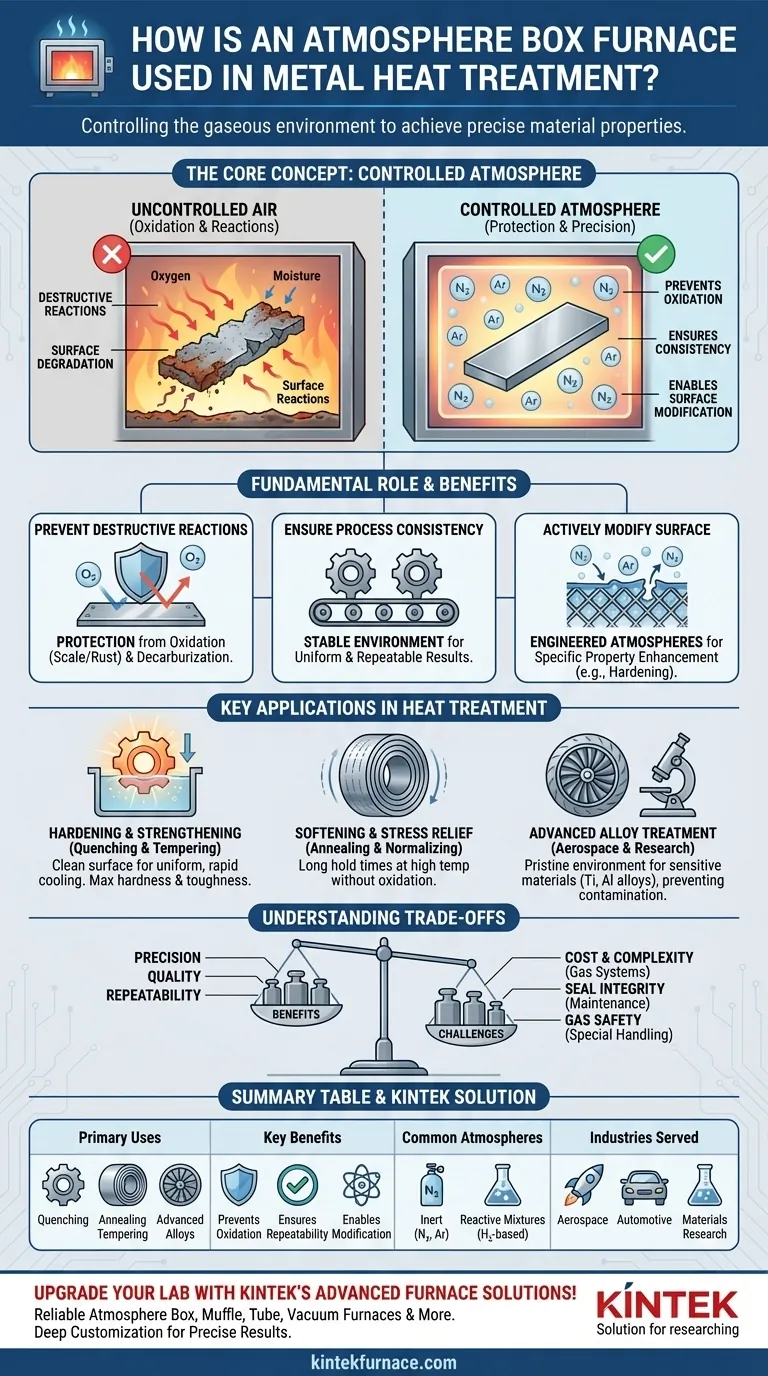

The Fundamental Role of a Controlled Atmosphere

Many believe a furnace's only job is to provide heat. However, in high-performance applications, the gas surrounding the metal is just as important as the temperature. At elevated temperatures, metals become highly reactive with the oxygen and moisture present in normal air.

To Prevent Destructive Reactions

The primary function of a controlled atmosphere is protection. By replacing the air inside the furnace with a specific gas or gas mixture (like nitrogen or argon), you create a protective shield around the workpiece.

This shield prevents oxidation (scaling or rust) and decarburization (the loss of carbon from the surface of steel), both of which degrade the material's surface finish, dimensions, and mechanical properties.

To Ensure Process Consistency

The composition of ambient air can fluctuate. A controlled atmosphere furnace eliminates this variability by providing a stable, known environment for every batch.

This guarantees that the heat treatment process is uniform and repeatable, which is essential for quality control in industries like aerospace and automotive manufacturing where component failure is not an option.

To Actively Modify the Surface

In some advanced processes, the atmosphere is not just protective (inert) but active. It can be engineered to intentionally interact with the metal's surface.

These atmospheres can carry elements that diffuse into the material to enhance specific characteristics, such as hardening the surface while maintaining a ductile core.

Key Applications in Heat Treatment

By mastering the furnace environment, engineers can precisely manipulate a material's final characteristics. The atmosphere furnace is the tool that makes these precise transformations possible.

Hardening and Strengthening (Quenching & Tempering)

For steel components, achieving maximum hardness and toughness through quenching and tempering is common. A controlled atmosphere ensures the part's surface is clean and free of insulating scale, allowing for the uniform and rapid cooling that is critical to a successful quench.

Softening and Stress Relief (Annealing & Normalizing)

Processes like annealing, which soften metal and relieve internal stresses, often require long hold times at high temperatures. An inert atmosphere is crucial to protect the material's surface from oxidation over these extended periods.

Advanced Alloy Treatment (Aerospace & Research)

In aerospace, high-performance materials like titanium and aluminum alloys are treated to optimize their strength-to-weight ratio and corrosion resistance. These sensitive alloys are intolerant of surface contamination, making a pure, controlled atmosphere absolutely essential.

Similarly, in materials research, an atmosphere furnace provides the pristine environment needed to study the effects of heat on new alloys without the interference of unwanted chemical reactions.

Understanding the Trade-offs

While powerful, an atmosphere furnace introduces complexities that are not present with simpler air furnaces. Objectively weighing these factors is key to making a sound investment.

Increased Cost and Complexity

These furnaces require gas delivery systems, precise flow controls, and robust seals to maintain the integrity of the internal atmosphere. This adds to the initial equipment cost and ongoing operational expense.

The Importance of Seal Integrity

The entire principle relies on a tightly sealed chamber. Any leak, however small, can compromise the atmosphere, ruin the workpiece, and negate the benefits of the system. Regular maintenance of seals and gaskets is critical.

Gas Selection and Safety

Different processes require different atmospheres—from inert gases like argon to reactive mixtures that may include hydrogen. Handling, storing, and mixing these gases requires specialized knowledge and strict safety protocols.

Making the Right Choice for Your Application

Your goal determines whether the precision of an atmosphere furnace is a necessity or an over-specification.

- If your primary focus is achieving specific mechanical properties without surface defects: An atmosphere furnace is essential to prevent oxidation and ensure the development of the desired microstructure.

- If your primary focus is research and development on sensitive alloys: A controlled atmosphere is non-negotiable for obtaining pure, repeatable results free from environmental contamination.

- If your primary focus is low-cost heat treatment of non-critical components: A standard air furnace may be sufficient, but you must accept the trade-off of post-process cleaning to remove surface scale.

Ultimately, mastering modern heat treatment requires understanding that you are not just controlling temperature, but the entire chemical environment in which the material is transformed.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Uses | Quenching, annealing, tempering for metal hardening, softening, and stress relief |

| Key Benefits | Prevents oxidation and decarburization, ensures process repeatability, enables surface modification |

| Common Atmospheres | Inert gases (e.g., nitrogen, argon), reactive mixtures (e.g., hydrogen-based) |

| Industries Served | Aerospace, automotive, materials research |

| Key Considerations | Higher cost, requires gas systems and seal maintenance, essential for sensitive alloys |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable atmosphere box furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering consistent, oxidation-free heat treatment for metals. Contact us today to discuss how we can enhance your processes and achieve superior results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance