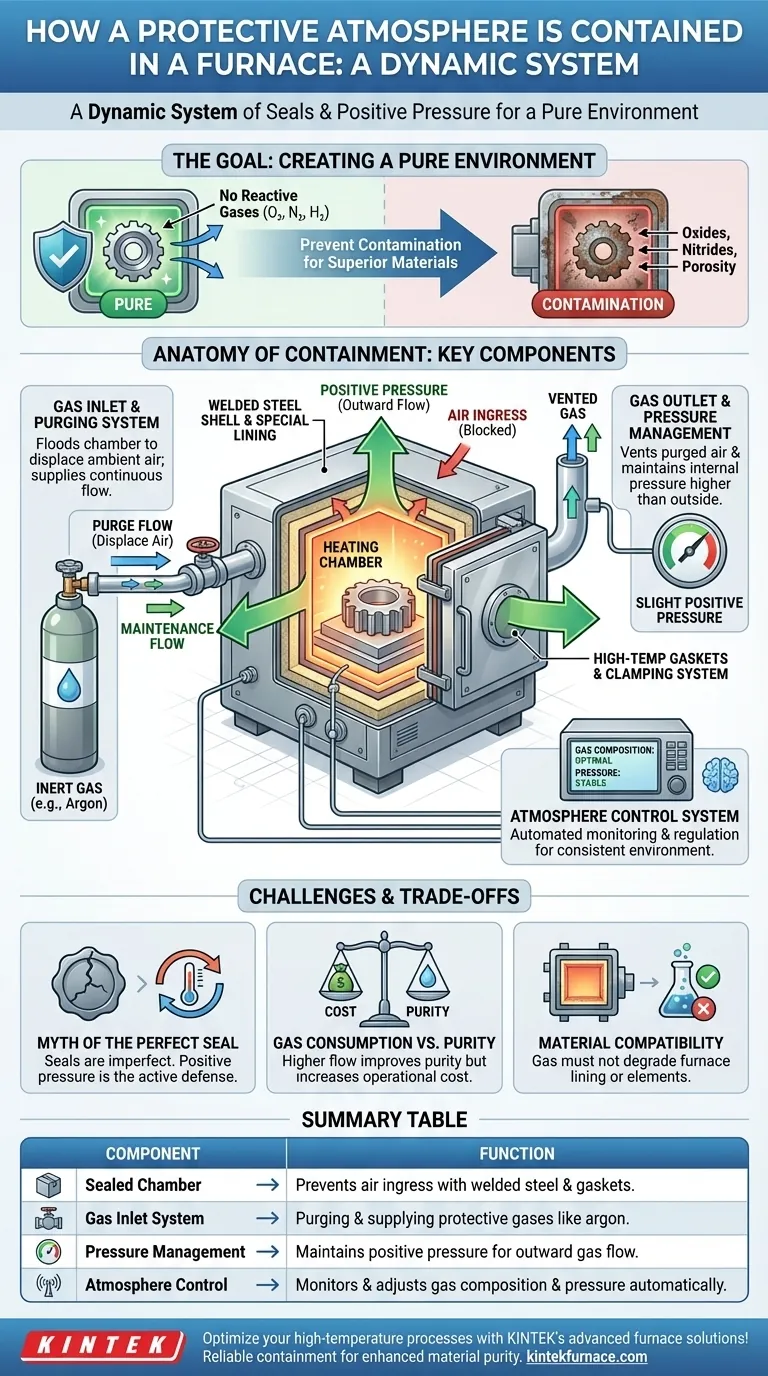

A protective atmosphere is contained within a furnace through the engineered combination of a physically sealed chamber and a dynamic gas management system. This design first purges the furnace of reactive ambient air, then continuously supplies a specific gas mixture at a slight positive pressure. This ensures that any potential leakage flows outward, preventing external contaminants like oxygen from entering and compromising the material being processed.

Containing a protective atmosphere is less about creating a perfect, hermetic seal and more about engineering a dynamic system. The goal is to use positive gas pressure to ensure a constant outward flow, actively preventing reactive air from infiltrating the high-temperature processing chamber.

The Goal: Creating a Pure Environment

The primary purpose of a protective atmosphere is to create an environment free of reactive gases like oxygen, nitrogen, and hydrogen. During high-temperature processes such as melting or heat treating, these gases can cause significant problems.

They can form unwanted oxides and nitrides or create porosity within the material's structure. By preventing this contamination, manufacturers can produce materials with superior purity, strength, and overall performance.

The Anatomy of Containment: Key System Components

A furnace's ability to contain a protective atmosphere relies on several interconnected components working in concert. It is not one single feature but an entire system designed for containment and control.

The Furnace Body and Sealing Mechanisms

The first line of defense is the furnace's physical structure. The outer shell is typically welded from steel plates to provide a robust, sealed enclosure. Inside, the furnace lining is constructed with energy-saving composite structures and special, corrosion-resistant refractory bricks designed to withstand both high temperatures and the specific chemical properties of the protective gas.

Crucially, sealing mechanisms are the most critical element. Furnace doors, sensor ports, and other openings are fitted with high-temperature gaskets and clamping systems. The furnace door seal is especially important and is intentionally strengthened to minimize leaks at this large, frequently used interface.

The Gas Inlet and Purging System

To establish the environment, the furnace is first purged. This involves flooding the chamber with the protective atmosphere gas—such as inert argon—through dedicated inlet pipes and valves.

This initial high-flow stage forcefully displaces the ambient air, pushing it out of the chamber. Once the oxygen level drops to the desired minimum, the purging cycle ends, and the system transitions to a maintenance flow rate.

The Gas Outlet and Pressure Management

A sealed furnace must have a controlled outlet. This is essential for venting the purged air and for maintaining the correct internal pressure during operation.

The system is designed to maintain a slight positive pressure inside the heating chamber. This means the pressure inside is marginally higher than the atmospheric pressure outside. This simple principle is the key to effective containment; if any microscopic leaks exist in the seals, the internal gas will flow out, preventing the much more damaging ingress of air.

The Atmosphere Control System

Modern furnaces use a dedicated atmosphere control system. This automated system uses sensors to monitor the composition and pressure of the gas inside the furnace.

It precisely regulates gas flow rates from the inlet, adjusting the mixture as needed to maintain the ideal environment throughout the heating and cooling cycle. This active management is what guarantees process consistency and material quality.

Understanding the Practical Challenges and Trade-offs

While the principles are straightforward, achieving perfect atmospheric containment involves navigating real-world engineering challenges.

The Myth of the Perfect Seal

No mechanical seal is truly perfect, especially under extreme thermal cycling where materials expand and contract. Relying solely on seals is a flawed strategy. This is precisely why the principle of positive pressure is non-negotiable, as it provides an active defense against the inevitable imperfections of any seal.

Gas Consumption vs. Purity

There is a direct trade-off between the cost of the protective gas and the purity of the environment. A higher gas flow rate creates a stronger positive pressure and purges contaminants more effectively, but it also increases operational costs. The goal is to find the minimum flow rate that reliably prevents contamination for a specific process.

Material Compatibility

The furnace's internal components, including the refractory lining and the heating elements themselves, must be compatible with the protective atmosphere. Certain gases can become reactive at very high temperatures, potentially degrading furnace components over time. The choice of gas and furnace materials must be carefully aligned.

Making the Right Choice for Your Process

Understanding how containment works allows you to align furnace capabilities with your specific operational goals.

- If your primary focus is achieving maximum material purity: Invest in a furnace with superior sealing integrity, robust door clamps, and a precise, sensor-driven atmosphere control system.

- If your primary focus is cost-effective production: Emphasize optimizing purge cycles and maintenance flow rates to minimize gas consumption while still meeting your required quality standards.

- If your primary focus is operational reliability and safety: Implement a strict maintenance schedule for inspecting and replacing door seals, gaskets, and verifying the accuracy of pressure sensors.

Ultimately, mastering atmosphere containment is about managing a controlled, dynamic flow, not just building a static, sealed box.

Summary Table:

| Component | Function |

|---|---|

| Sealed Chamber | Prevents air ingress with welded steel and high-temperature gaskets |

| Gas Inlet System | Purging and supplying protective gases like argon |

| Pressure Management | Maintains slight positive pressure to ensure outward gas flow |

| Atmosphere Control | Monitors and adjusts gas composition and pressure automatically |

Optimize your high-temperature processes with KINTEK's advanced furnace solutions! We specialize in Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique experimental needs. Our expertise in R&D and in-house manufacturing ensures reliable containment of protective atmospheres, enhancing material purity and efficiency. Contact us today to discuss how we can support your laboratory goals!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments