In any thermal process, uniformity is the foundation of quality and repeatability. Uniform heating ensures that every point within a material or product load receives the exact same thermal treatment. This consistency is the key to preventing defects like warping or internal stress, guaranteeing predictable material properties, and ultimately producing a higher quality, more reliable product.

The core challenge in any furnace is the battle against thermal gradients—the natural tendency for temperature to vary from one point to another. Uniform heating directly solves this by ensuring consistent energy transfer, which is the only way to achieve predictable material properties, minimize waste, and maximize operational efficiency.

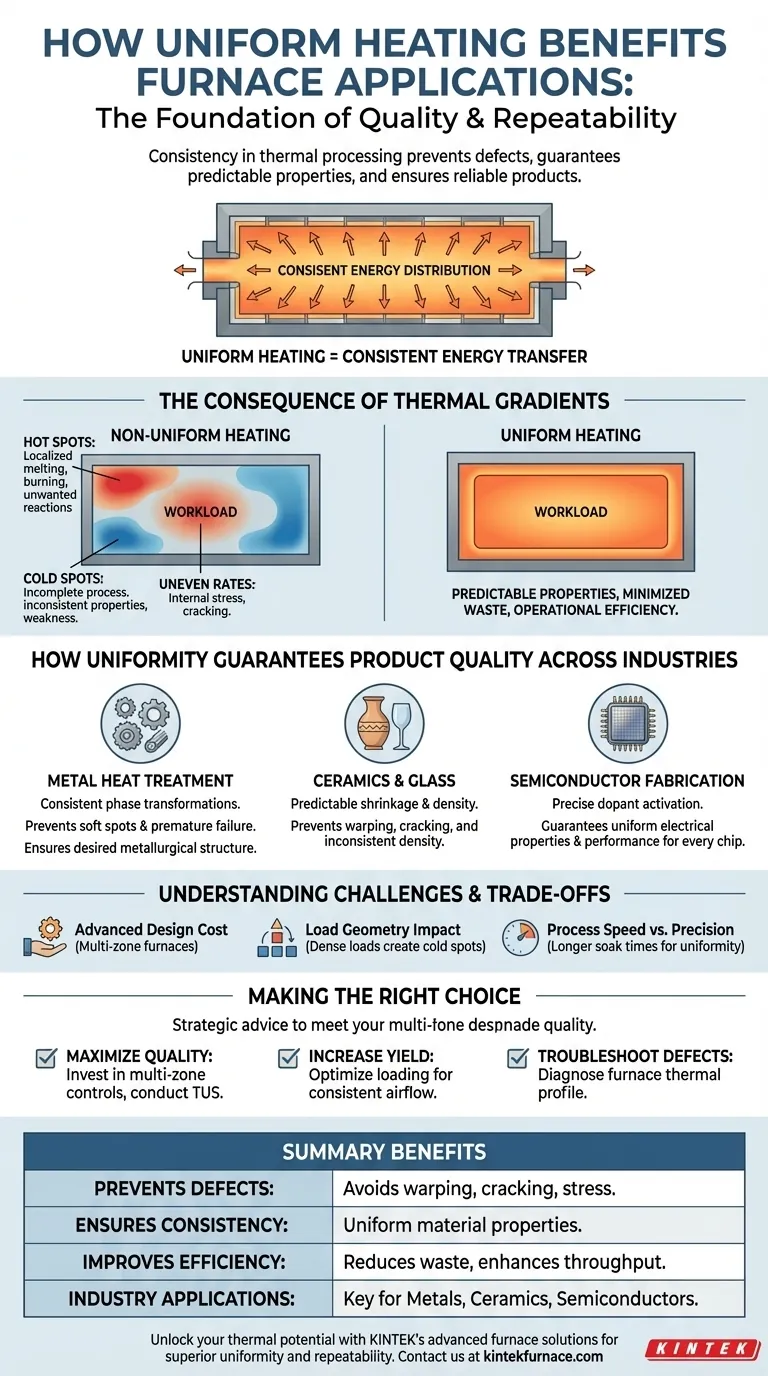

The Consequence of Thermal Gradients

The fundamental goal of a furnace is to deliver energy to a workload. When that energy delivery is uneven, it creates destructive temperature differences known as thermal gradients.

The Problem with Hot and Cold Spots

Hot spots are localized areas that are significantly hotter than the target temperature. They can cause localized melting, burning, or undesirable chemical reactions, effectively ruining that portion of the product.

Cold spots are areas that fail to reach the target temperature. In these zones, the desired process—like a metallurgical phase change or a chemical cure—may not complete, resulting in inconsistent material properties and structural weaknesses.

Impact on Heating and Cooling Rates

Uniformity isn't just about the final temperature; it's also about the rate of temperature change. If one part of a component heats or cools faster than another, it introduces internal stresses. For brittle materials like ceramics or complex metal parts, this stress can easily lead to cracking.

How Uniformity Guarantees Product Quality

Achieving uniform heating directly translates to measurable improvements in the final product across various high-stakes industries. This is not a minor optimization; it is a prerequisite for success.

In Metal Heat Treatment (Annealing, Hardening)

For metals, specific temperatures trigger critical phase transformations that determine properties like hardness and ductility. Non-uniform heating means one part of a component could be fully hardened while another remains soft, leading to premature failure in the field.

Uniformity ensures the entire component achieves the desired metallurgical structure, guaranteeing consistent performance.

In Ceramics and Glass (Sintering, Firing)

Ceramic and glass products shrink and densify during firing. If this process occurs unevenly due to thermal gradients, the result is warping, cracking, and inconsistent density.

Uniform heating ensures predictable, even shrinkage, which is essential for manufacturing dimensionally accurate and structurally sound ceramic components.

In Semiconductor Fabrication (Wafer Annealing)

In semiconductor manufacturing, even a one-degree variation across a silicon wafer can ruin thousands of microchips. The process of dopant activation is extremely sensitive to temperature.

Uniform heating is non-negotiable in this field. It guarantees that every chip on the wafer has the exact same electrical properties and performance characteristics.

Understanding the Challenges and Trade-offs

While the benefits are clear, achieving perfect uniformity involves technical and financial considerations.

The Cost of Advanced Design

Simple furnaces with single heating zones are prone to gradients. Achieving high uniformity often requires more sophisticated designs, such as multi-zone furnaces with independent controllers that can adjust energy output to different areas of the chamber.

These systems also rely on advanced materials for heating elements and insulation, increasing the initial capital investment.

The Impact of Load Geometry

The product itself can be the biggest enemy of uniformity. A densely packed load can shield its own center, creating a significant cold spot. Similarly, parts with both thick and thin sections will naturally heat at different rates.

Proper process design involves considering how to arrange the workload within the furnace to facilitate uniform heat transfer via convection, conduction, and radiation.

Process Speed vs. Precision

In some cases, achieving the highest level of uniformity requires slower heating rates (soak times) to allow the temperature to equalize throughout the workload. This can create a trade-off between the quality of the product and the throughput of the furnace.

Making the Right Choice for Your Goal

Your approach to thermal uniformity should be driven by your primary objective.

- If your primary focus is maximizing product quality and repeatability: Invest in multi-zone control systems and conduct regular temperature uniformity surveys (TUS) to map and correct your furnace's performance.

- If your primary focus is increasing process yield and reducing scrap: Analyze your loading procedures to ensure they are consistent and optimized for even airflow and heat exposure.

- If your primary focus is troubleshooting existing defects: Your first step should be to diagnose the thermal profile of your furnace to identify if and where hot or cold spots are contributing to the failures.

By mastering thermal uniformity, you transition from simply managing a process to engineering a predictable, high-quality outcome.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Defects | Avoids warping, cracking, and internal stress from thermal gradients. |

| Ensures Consistency | Guarantees uniform material properties and predictable outcomes. |

| Improves Efficiency | Reduces waste and enhances operational throughput. |

| Industry Applications | Key for metal heat treatment, ceramics firing, and semiconductor fabrication. |

Unlock the full potential of your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior uniformity, quality, and repeatability. Don't let thermal gradients hold you back—contact us today to discuss how we can optimize your furnace applications and drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure