At its core, the tilting capability of a furnace provides dynamic control over how material moves through the hot zone. By adjusting the furnace angle, operators can precisely manage material flow, residence time, and discharge speed, directly enhancing the flexibility and efficiency of the thermal process.

The ability to tilt a furnace transforms it from a static heating chamber into a dynamic processing tool. This capability is not merely for loading or unloading; it is a critical variable for optimizing the entire treatment cycle for different materials and production goals.

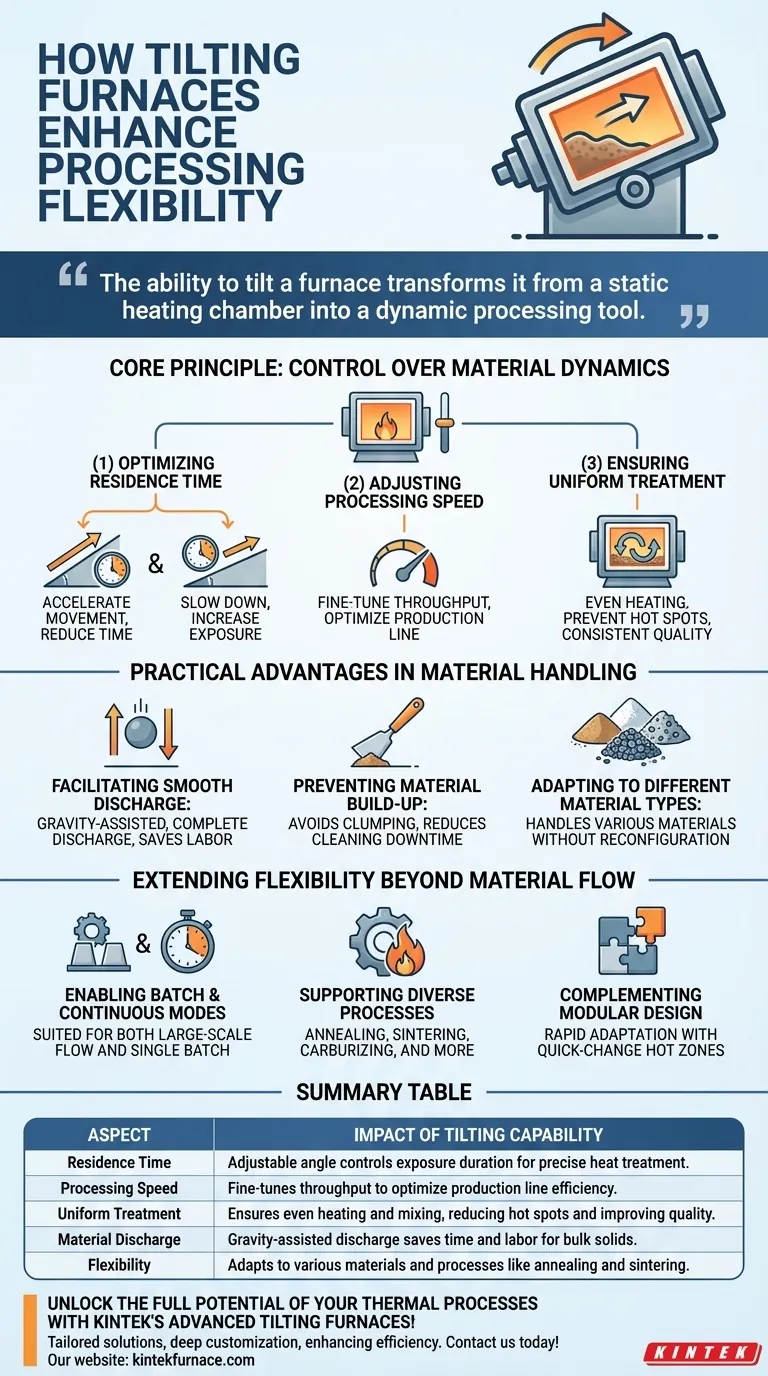

The Core Principle: Control Over Material Dynamics

A tilting furnace gives operators direct influence over the physics of the material being processed. This control is the foundation of its enhanced flexibility.

Optimizing Residence Time

The angle of tilt directly dictates how long material resides within the furnace's effective heating zone. A steeper angle accelerates movement, reducing residence time, while a shallower angle slows it down, increasing exposure time.

Adjusting Processing Speed

For continuous or semi-continuous operations, the tilt angle serves as a throttle for throughput. Operators can fine-tune the processing speed to match upstream and downstream capacity, optimizing the entire production line.

Ensuring Uniform Treatment

In rotary furnaces, tilting complements the rotation by promoting a tumbling and mixing action. This ensures that the entire bulk material is uniformly exposed to the heat source, preventing hot spots and ensuring consistent quality.

Practical Advantages in Material Handling

This dynamic control translates into significant, tangible benefits for day-to-day operations, particularly when dealing with bulk solids.

Facilitating Smooth Discharge

Tilting provides a simple, gravity-assisted method for complete and efficient discharge. This is far more effective than relying on manual raking or complex internal mechanisms, saving time and labor.

Preventing Material Build-up

For materials prone to clumping or sticking, the ability to adjust the tilt and rotation helps prevent unwanted build-up on the furnace walls. This reduces downtime required for cleaning and improves overall operational efficiency.

Adapting to Different Material Types

Different materials have different flow characteristics. The tilting function allows the furnace to be easily adapted for a wide range of materials, from fine powders to larger aggregates, without mechanical reconfiguration.

Understanding the Trade-offs

While highly beneficial, the tilting capability introduces factors that require careful consideration.

Increased Mechanical Complexity

A tilting mechanism adds moving parts, hydraulics, and control systems. This inherently increases the mechanical complexity of the furnace, which can translate to higher initial costs and more demanding maintenance schedules compared to a static unit.

Process Control Demands

The flexibility of a variable tilt angle is also a process variable that must be controlled. Inconsistent use of the tilt function can lead to batch-to-batch variability in product quality. Achieving repeatable results requires well-defined procedures and trained operators.

Extending Flexibility Beyond Material Flow

The control offered by tilting is a key enabler for other flexible features, making the furnace a highly adaptable asset.

Enabling Batch and Continuous Modes

The combination of rotation and tilt makes the furnace uniquely suited for both batch and continuous operations. A batch can be loaded, processed, and discharged, or a continuous flow can be established for large-scale production.

Supporting Diverse Processes

Precise control over residence time and heat exposure is critical for a range of thermal processes. This makes the tilting furnace suitable for everything from annealing and sintering to more complex reactions like carburizing.

Complementing Modular Design

In furnaces with modular designs, the tilting function works in concert with features like quick-change hot zones. This allows a single furnace body to be rapidly adapted for processing vastly different materials, from standard metals to advanced ceramics or superalloys.

Making the Right Choice for Your Goal

To leverage this capability effectively, align its use with your primary processing objective.

- If your primary focus is maximum throughput: Use a steeper tilt angle to facilitate rapid, continuous flow and quick discharge, minimizing cycle time.

- If your primary focus is process precision: Use subtle changes in the tilt angle to meticulously control residence time for materials that are highly sensitive to thermal exposure.

- If your primary focus is operational versatility: Leverage the full range of tilt to switch between batch and continuous modes and to adapt the furnace for materials with different handling characteristics.

Ultimately, mastering the tilting function empowers you to tailor the furnace's performance precisely to the material and the desired outcome.

Summary Table:

| Aspect | Impact of Tilting Capability |

|---|---|

| Residence Time | Adjustable angle controls exposure duration for precise heat treatment. |

| Processing Speed | Fine-tunes throughput to optimize production line efficiency. |

| Uniform Treatment | Ensures even heating and mixing, reducing hot spots and improving quality. |

| Material Discharge | Gravity-assisted discharge saves time and labor for bulk solids. |

| Flexibility | Adapts to various materials and processes like annealing and sintering. |

Unlock the full potential of your thermal processes with KINTEK's advanced tilting furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and flexibility. Contact us today to discuss how our furnaces can transform your operations!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation