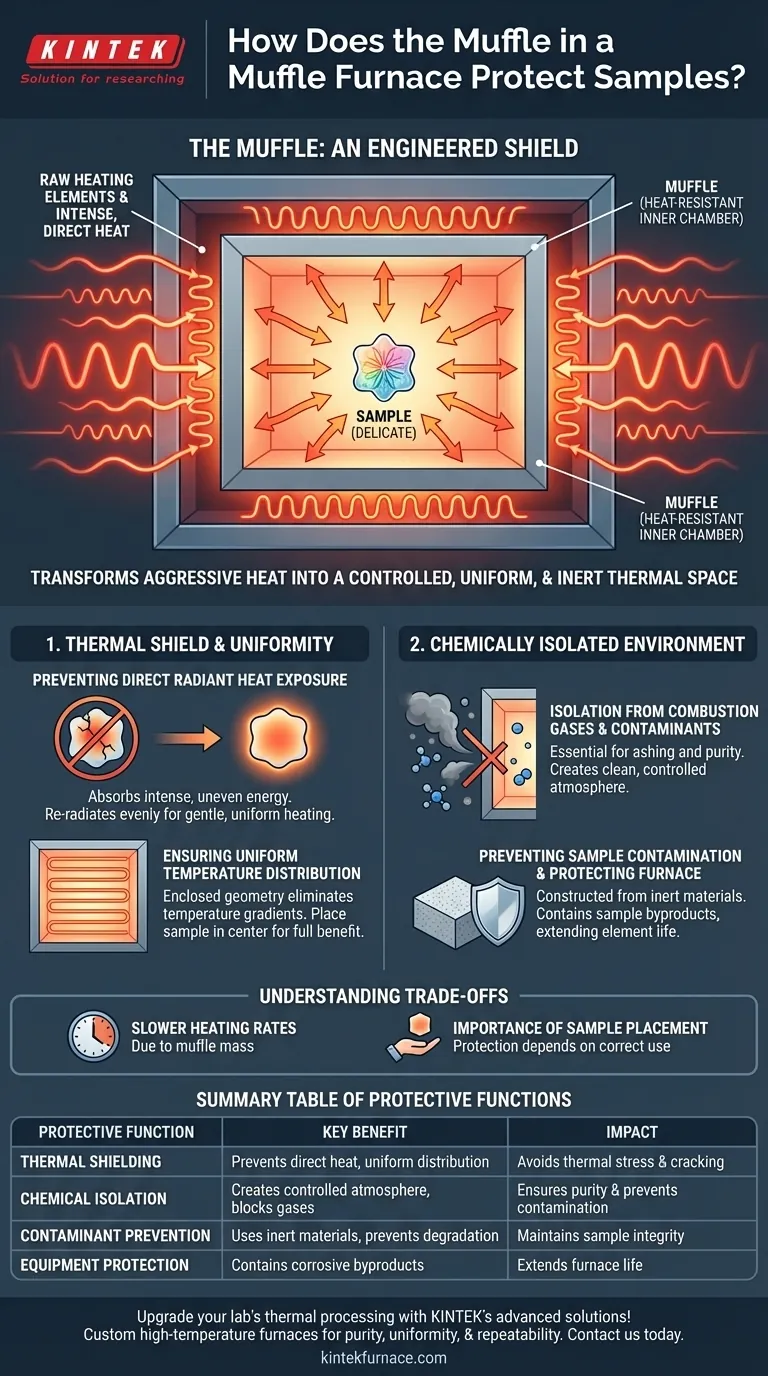

At its core, a muffle furnace's protective capability comes from its primary component: the muffle. This is a heat-resistant inner chamber that acts as a sophisticated barrier, physically separating your sample from the furnace's raw heating elements. It transforms the intense, direct heat into a uniform, gentle thermal environment while also isolating the sample from chemical contaminants.

The muffle is not just a box; it is an engineered shield. Its true function is to transform the furnace's aggressive, localized heat into a controlled, uniform, and chemically inert thermal space, ensuring the integrity of your sample and the repeatability of your process.

The Muffle as a Thermal Shield

The most immediate function of the muffle is to manage heat transfer. It stands between the intense energy source and the delicate sample, ensuring the heating process is controlled and uniform rather than harsh and unpredictable.

Preventing Direct Radiant Heat Exposure

Heating elements, such as resistance wires, get extremely hot and radiate energy directly. If a sample were exposed to this, different parts of it would heat at vastly different rates, causing thermal stress, localized overheating, or inconsistent reactions.

The muffle absorbs this intense radiant energy and then re-radiates it evenly from all its interior surfaces. This indirect heating mechanism ensures the sample is warmed gently and uniformly from all sides.

Ensuring Uniform Temperature Distribution

The muffle’s enclosed, regular geometry (typically a box) is designed to eliminate hot and cold spots. The heated air and radiant energy circulate within this chamber, creating a large, stable zone of consistent temperature.

This is why proper procedure dictates placing samples in the center of the chamber, equidistant from the walls, to take full advantage of this thermal equilibrium.

Creating a Chemically Isolated Environment

Beyond thermal management, the muffle creates a pristine environment by isolating the sample from the furnace's operational byproducts and the outside world. This chemical separation is critical for achieving pure and predictable results.

Isolation from Combustion Gases

In furnaces where heat is generated by combustion, the muffle is essential for protecting the sample from direct contact with fuel byproducts and flue gases.

This creates a clean, often oxygen-free or controlled, atmosphere inside the muffle. This is non-negotiable for processes like ashing, where the goal is to measure content without introducing chemical interference.

Preventing Sample Contamination

Muffles are constructed from chemically inert, high-purity refractory materials like alumina. This material is chosen for its ability to withstand extreme temperatures without degrading or releasing particles that could contaminate the sample.

This ensures that the only changes to your sample are a result of the intended thermal process, not a reaction with the furnace itself.

Protecting the Furnace Elements

This protection is a two-way street. Many thermal processes, such as binder burnout, release corrosive fumes or vapors.

The muffle contains these byproducts, preventing them from attacking and degrading the expensive heating elements and furnace insulation. This extends the life of the furnace and ensures its performance remains consistent over time.

Understanding the Trade-offs

While the muffle provides critical protection, its design principles introduce inherent trade-offs that you must be aware of to manage your process effectively.

Slower Heating Rates

Because the muffle acts as a thermal intermediary, muffle furnaces generally have slower heat-up and cool-down times compared to furnaces with exposed elements. The muffle’s mass must first be heated before it can effectively heat the sample. This is the trade-off for achieving superior temperature uniformity.

Importance of Sample Placement

The protection offered by the muffle is not absolute; it depends on correct use. Placing a sample too close to an interior wall or blocking air circulation can compromise the uniform heating zone and lead to inaccurate results, partially defeating the purpose of the muffle.

Making the Right Choice for Your Process

Understanding how the muffle protects your sample allows you to tailor your procedure to your specific goal.

- If your primary focus is material purity (e.g., ashing or trace metal analysis): Rely on the muffle to shield your sample from combustion gases and any potential contaminants from the furnace structure.

- If your primary focus is structural integrity (e.g., firing ceramics or annealing metals): Leverage the muffle's ability to provide gentle, uniform radiant heating to prevent thermal shock, warping, and cracking.

- If your primary focus is process repeatability: Always place your sample in the center of the chamber and allow the furnace to fully stabilize to ensure you are operating within the muffle's consistent thermal zone.

By understanding these protective functions, you can move from simply using the furnace to truly controlling your thermal process.

Summary Table:

| Protective Function | Key Benefit |

|---|---|

| Thermal Shielding | Prevents direct radiant heat, ensuring uniform temperature distribution and avoiding thermal stress |

| Chemical Isolation | Creates a controlled atmosphere, protecting samples from combustion gases and contamination |

| Contaminant Prevention | Uses inert materials to avoid sample degradation and maintain purity |

| Equipment Protection | Extends furnace life by containing corrosive byproducts from samples |

Upgrade your lab's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for purity, uniformity, and repeatability. Contact us today to discuss how our tailored furnace solutions can enhance your results and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis