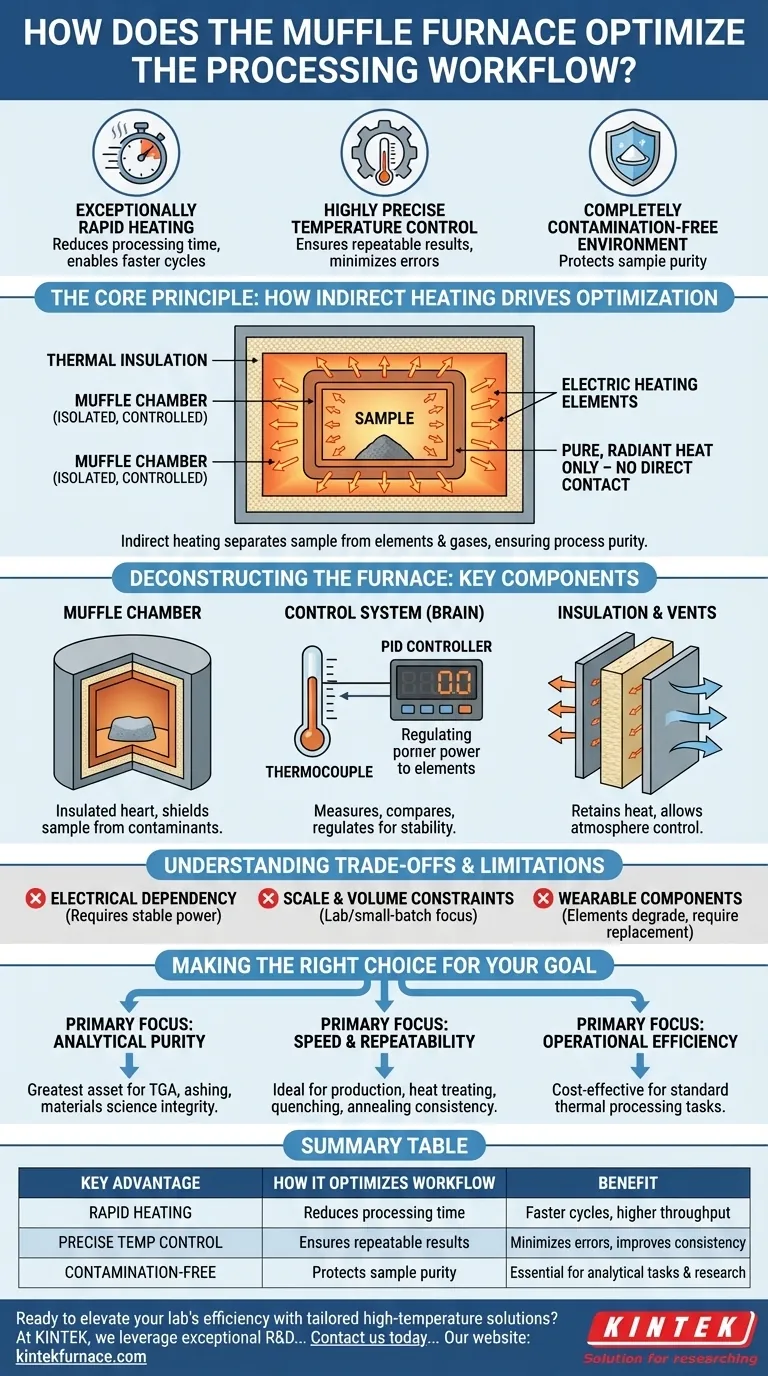

In short, a muffle furnace optimizes processing workflows by delivering three key advantages: exceptionally rapid heating, highly precise temperature control, and a completely contamination-free environment for the material being processed. This combination allows for faster, more repeatable, and purer results at a relatively low operational cost.

The furnace's core design principle is indirect heating. By physically separating the material inside an isolated chamber (the "muffle") from the electric heating elements, it guarantees that the sample is never exposed to combustion gases or other impurities, enabling a level of process control that direct-fire methods cannot match.

The Core Principle: How Indirect Heating Drives Optimization

The defining characteristic of a muffle furnace is not just its ability to get hot, but how it generates and contains that heat. This method is the foundation of its efficiency.

An Isolated, Controlled Environment

A muffle furnace places the sample inside a sealed chamber, often made of a high-temperature ceramic. The actual heating elements are located outside this chamber.

This design completely isolates the workpiece from the heat source. It ensures that the only thing affecting the sample is pure, radiant heat, not flames or chemical byproducts from combustion.

Resistance Heating for Precision

Modern muffle furnaces use electrical energy. Electricity is passed through high-resistance heating elements, typically made of materials like Kanthal or nickel-chromium.

As these elements resist the electrical current, they glow red-hot, converting electrical energy into thermal energy with high efficiency. This heat then radiates through the muffle chamber walls, heating the air and the sample inside uniformly.

Deconstructing the Furnace: Key Components and Their Roles

Each part of a muffle furnace is engineered to contribute to its overall precision and speed. Understanding these components reveals how it achieves such reliable performance.

The Muffle Chamber

This is the insulated heart of the furnace. It contains the sample and shields it from any external contaminants, ensuring process purity. This is critical for applications like ashing, chemical analysis, or creating sensitive materials where even minor impurities can ruin a result.

The Control System

This is the furnace's brain. A thermocouple inside the chamber constantly measures the internal temperature and sends that data to a digital temperature controller.

The controller compares the actual temperature to the user's setpoint. It then precisely regulates the amount of electricity sent to the heating elements to maintain the target temperature with remarkable stability.

The Insulation and Vents

The chamber is surrounded by thick layers of refractory insulation to prevent heat from escaping. This allows the furnace to reach its maximum temperature quickly (often in about an hour) and maintain it with less energy.

Air intake and exhaust ports allow for control over the atmosphere inside the chamber, which is necessary for processes that require specific oxidative or other atmospheric conditions.

Understanding the Trade-offs and Limitations

While highly effective, a muffle furnace is not the universal solution for every heating application. Its design comes with specific trade-offs.

Electrical Dependency

The furnace is entirely dependent on a stable supply of electricity. Unlike fuel-burning furnaces, it cannot operate in off-grid or power-unstable environments.

Scale and Volume Constraints

Muffle furnaces are typically designed for laboratory-scale or small-batch industrial work. Their design for precision and purity does not scale efficiently for massive operations like smelting tons of ore, which require larger, direct-fire furnaces.

Wearable Components

The heating elements operate under extreme thermal stress and will eventually degrade. They are consumable parts that require periodic inspection and replacement, which is a key maintenance consideration.

Making the Right Choice for Your Goal

The decision to use a muffle furnace should be based on your specific processing priorities.

- If your primary focus is analytical purity: The contamination-free environment provided by the muffle chamber is its greatest asset, ensuring the integrity of samples for TGA, ashing, or materials science research.

- If your primary focus is speed and repeatability: The digital control system and rapid heating cycles are ideal for production workflows like heat treating, quenching, or annealing small parts where consistency is paramount.

- If your primary focus is operational efficiency: Modern designs offer excellent energy efficiency and process automation, making them a cost-effective tool for a wide range of standard thermal processing tasks.

By understanding its principle of controlled, indirect heat, you can confidently leverage the muffle furnace to enhance the precision and efficiency of your work.

Summary Table:

| Key Advantage | How It Optimizes Workflow |

|---|---|

| Rapid Heating | Reduces processing time, enabling faster cycles and higher throughput in labs and production. |

| Precise Temperature Control | Ensures repeatable results, minimizing errors and improving consistency for sensitive experiments. |

| Contamination-Free Environment | Protects sample purity, essential for analytical tasks like ashing and materials research. |

Ready to elevate your lab's efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our solutions can optimize your processing workflow and deliver superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis