At its core, the insulation system in a muffle furnace functions by using high-purity fibrous alumina to create a highly efficient thermal barrier. This material traps the intense heat generated by the electrical elements within the furnace chamber, preventing it from escaping. This ensures the furnace can reach and maintain very high temperatures with minimal energy loss while keeping the exterior safe to touch.

The function of muffle furnace insulation is not merely to trap heat. It is to create a precisely controlled, isolated thermal environment, separating the extreme internal temperatures from the user and the outside world, which is the key to its efficiency, safety, and process purity.

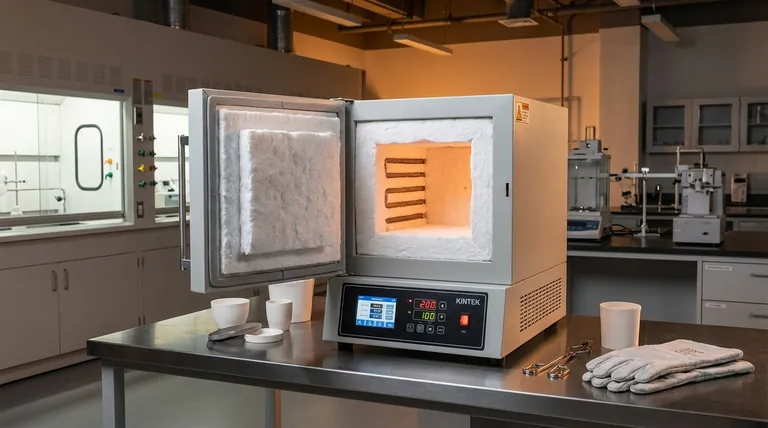

The Core Principle: Creating a Thermal Fortress

A muffle furnace's primary job is to generate and contain extreme heat. The insulation system is the most critical component for achieving this, working on multiple levels to ensure performance and safety.

The Primary Insulator: Fibrous Alumina

The workhorse of the system is high-purity fibrous alumina. This advanced ceramic material is chosen for its exceptionally low thermal conductivity, meaning it is a very poor conductor of heat.

Its fibrous structure traps millions of tiny air pockets, further inhibiting the transfer of heat. This allows the interior chamber to reach temperatures exceeding 1000°C while the heat barely penetrates the insulation layer.

The "Muffle" as an Isolation Chamber

The term muffle refers to the insulated inner chamber that holds the workpiece. The fibrous alumina insulation forms the walls of this muffle.

This design enables a principle called indirect heating. The heating elements warm the chamber, and the chamber then heats the sample through radiation and convection. The sample never directly contacts the heating elements, which prevents contamination and ensures uniform heating.

How Heat is Generated and Trapped

Electrical resistance elements, often made of materials like Kanthal, generate intense heat when electricity is passed through them.

The fibrous alumina insulation effectively reflects this radiant heat back into the chamber, creating a stable, uniform temperature environment. This heat containment is what allows the furnace to operate efficiently.

More Than Insulation: A Complete Thermal Management System

Effective insulation is part of a larger system designed to manage heat flow and ensure safety. A modern muffle furnace doesn't rely on a single material but on a multi-layered design.

The Double-Layer Steel Structure

Most muffle furnaces feature a double-layer steel structure or casing. An air gap is intentionally left between the inner wall (close to the insulation) and the outer wall.

This air gap acts as an additional, powerful layer of insulation, significantly reducing the amount of heat that reaches the exterior surface.

The Role of the Cooling Fan

To further guarantee user safety, a cooling fan is often integrated into the furnace casing.

This fan actively circulates air within the space between the inner and outer walls. It draws heat away from the furnace's internal structure and expels it, keeping the exterior panels at a safe temperature even during high-temperature operation.

Understanding the Benefits and Trade-offs

The design of the insulation system directly impacts the furnace's performance, creating clear benefits but also inherent operational trade-offs.

Benefit: Energy Efficiency

The high-performance fibrous alumina insulation directly translates to energy savings. By preventing heat from escaping, less power is required to maintain the target temperature, reducing operational costs.

Benefit: Process Purity and Uniformity

The muffle design, made possible by the insulation, guarantees a clean heating environment. This is critical for applications like ashing, materials testing, or chemical analysis where contamination from combustion byproducts would ruin the results.

Trade-off: Thermal Mass and Cooldown Times

A significant trade-off of a highly effective insulation system is slow cooldown. Because the system is designed to retain heat so well, it naturally takes a long time for the furnace to cool back to room temperature after a cycle. This must be factored into any workflow planning.

Making the Right Choice for Your Goal

Understanding the insulation system allows you to align the furnace's capabilities with your specific needs.

- If your primary focus is energy efficiency: The quality and thickness of the fibrous alumina insulation are the most critical factors for minimizing power consumption.

- If your primary focus is process purity: The integrity of the muffle chamber is key, as it provides the essential barrier between your sample and the heating elements.

- If your primary focus is user safety: Look for a comprehensive system that includes not just insulation but also a double-wall casing and an active cooling fan.

By understanding the insulation as an integrated thermal system, you can better control your processes and achieve more consistent, reliable results.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Fibrous Alumina Insulation | Traps heat and creates a thermal barrier | High energy efficiency and temperature stability |

| Muffle Chamber | Isolates sample from heating elements | Ensures process purity and uniform heating |

| Double-Layer Steel Structure | Provides additional insulation with air gap | Enhances safety by reducing exterior heat |

| Cooling Fan | Circulates air to dissipate heat | Maintains safe exterior temperatures during operation |

| Indirect Heating | Heats sample via chamber radiation/convection | Prevents contamination and improves reliability |

Optimize your laboratory's thermal processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency, safety, and results. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation