In short, the insulation in a muffle furnace is the single most critical component for its efficiency. By creating a highly effective thermal barrier, it drastically reduces the amount of energy required to achieve and maintain high temperatures. This core function of heat retention directly leads to lower energy consumption, faster heating speeds, and more stable processing conditions.

The true value of muffle furnace insulation extends beyond simple energy savings. It is the foundation for performance, enabling the rapid heating, temperature uniformity, and stability that are essential for reliable and repeatable results in any laboratory or industrial setting.

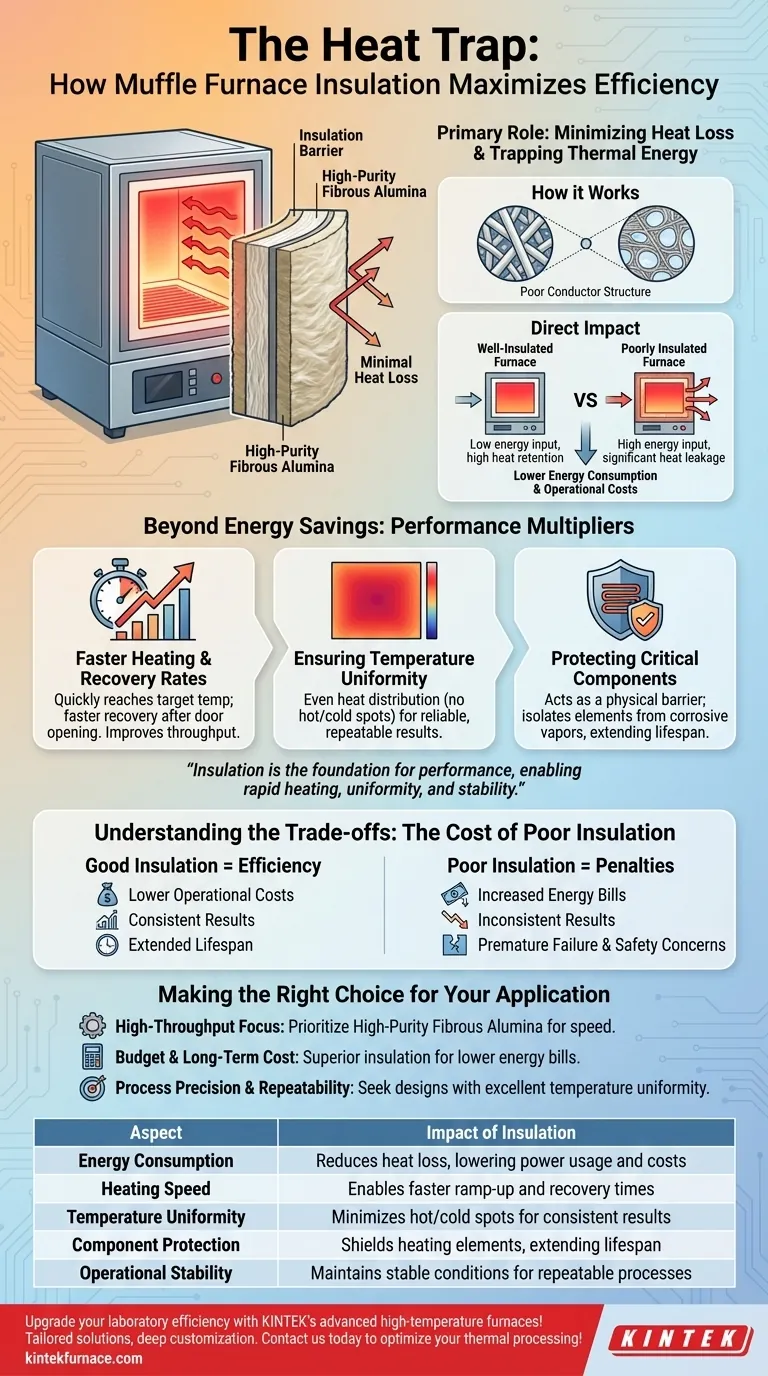

The Primary Role of Insulation: Minimizing Heat Loss

A muffle furnace's entire purpose is to generate and contain extreme heat. Insulation is the technology that makes this possible in an efficient and controlled manner.

How Insulation Traps Thermal Energy

Modern muffle furnaces use advanced insulation materials, most commonly high-purity fibrous alumina or polycrystalline wool. These materials are composed of countless microscopic fibers with air pockets trapped between them.

This structure is a poor conductor of heat. It works by preventing thermal energy from escaping the chamber through conduction and convection, effectively trapping it where it is needed most.

The Direct Impact on Energy Consumption

By preventing heat from leaking out, the insulation ensures the energy supplied by the heating elements is used almost exclusively to heat the chamber and its contents.

A poorly insulated furnace constantly bleeds heat into the surrounding environment. Its heating elements must work continuously just to compensate for this loss, leading to significantly higher energy consumption and operational costs.

Beyond Energy Savings: The Performance Multipliers

While reducing energy bills is a clear benefit, superior insulation unlocks several other performance advantages that are often even more critical for technical applications.

Achieving Faster Heating and Recovery Rates

Because a well-insulated furnace retains thermal energy so effectively, it can reach its target temperature much more quickly.

This principle also applies to temperature recovery. When the furnace door is opened and closed, a well-insulated chamber loses less heat and therefore returns to its setpoint temperature faster, improving throughput.

Ensuring Temperature Uniformity

High-quality insulation ensures that heat is distributed evenly throughout the chamber, minimizing hot and cold spots.

This temperature uniformity is crucial for processes that demand precision. It guarantees that every sample within the chamber is subjected to the exact same thermal conditions, leading to consistent and repeatable results.

Protecting Critical Components

The insulation also serves as the "muffle" itself, creating a physical barrier that isolates the heating elements from the main chamber.

This protects the delicate elements from potentially corrosive vapors and process off-gassing, extending their operational lifespan and reducing maintenance needs. It also protects the samples from direct contact with the heating source.

Understanding the Trade-offs: The Cost of Poor Insulation

Choosing a furnace with substandard insulation can seem like a cost-saving measure initially, but it carries significant long-term penalties.

Increased Operational Costs

The most immediate consequence of poor insulation is wasted energy. A furnace that cannot retain heat will have a higher power draw and lead to substantially larger electricity bills over its lifetime.

Inconsistent and Unreliable Results

Furnaces with inefficient insulation often suffer from poor temperature uniformity. This can compromise or invalidate experimental results, as you can no longer be certain that your samples were processed under the correct thermal conditions.

Reduced Component Lifespan and Safety Concerns

When heat escapes the chamber, the furnace's exterior can become dangerously hot. Furthermore, the heating elements must work harder and cycle more frequently, leading to premature failure and costly replacements.

Making the Right Choice for Your Application

Evaluating the insulation system is key to selecting the right muffle furnace. Your specific goals will determine which benefits are most important.

- If your primary focus is high-throughput processing: Prioritize a furnace that specifies high-purity fibrous alumina insulation, as this directly enables rapid heating and recovery times.

- If your primary focus is budget and long-term cost: Superior insulation is not a luxury; it directly translates to lower energy bills and is one of the most important features for cost-effective operation.

- If your primary focus is process precision and repeatability: Seek out designs that explicitly mention excellent temperature uniformity, which is a direct outcome of a high-performance insulation system.

Ultimately, understanding the role of insulation empowers you to look beyond the price tag and invest in a tool that delivers reliable performance efficiently.

Summary Table:

| Aspect | Impact of Insulation |

|---|---|

| Energy Consumption | Reduces heat loss, lowering power usage and costs |

| Heating Speed | Enables faster ramp-up and recovery times |

| Temperature Uniformity | Minimizes hot/cold spots for consistent results |

| Component Protection | Shields heating elements, extending lifespan |

| Operational Stability | Maintains stable conditions for repeatable processes |

Upgrade your laboratory efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs, enhancing performance and reducing costs. Contact us today to discuss how we can optimize your thermal processing!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation