At its core, the insulated chamber of a muffle furnace performs two critical functions: it isolates the material being heated from direct contact with the heating elements, and it creates an environment of highly uniform temperature. This design principle ensures that samples are heated evenly and without contamination from combustion byproducts or direct element interaction.

The insulated chamber functions by acting as a radiant box. Heating elements warm the chamber's ceramic walls, which then radiate heat uniformly onto the sample, preventing contamination and thermal "hot spots" that would occur with direct heating.

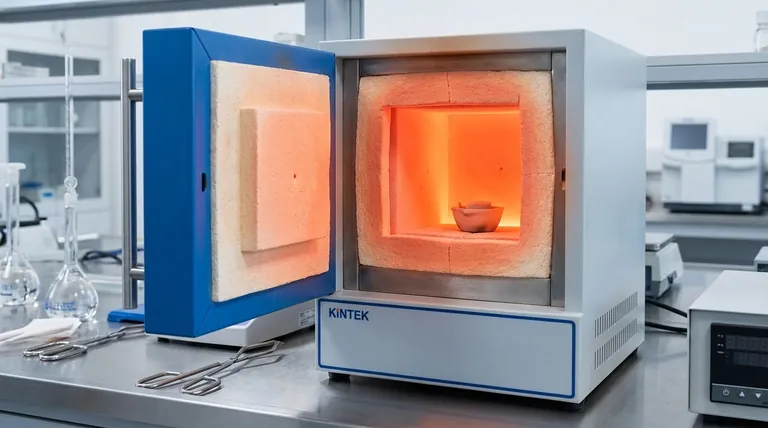

The Core Principle: An Isolated Heating Environment

A muffle furnace's chamber, or "muffle," creates a clean, controlled space for thermal processing. This separation is the defining feature that distinguishes it from simpler furnaces.

Isolating the Sample from the Heat Source

The heating elements, typically made of electrical resistance wire, are located outside the primary ceramic chamber. They heat the walls of the muffle, not the sample directly.

The muffle itself acts as a barrier, shielding the interior from any gases or particles shed by the heating elements. This is crucial for applications where sample purity is paramount.

The Role of High-Performance Ceramics

The muffle is constructed from advanced ceramic or refractory brick materials. These are chosen for their ability to withstand extreme temperatures without cracking, melting, or degrading.

This material integrity ensures the furnace has a long operational life and maintains a safe, contained environment even at temperatures exceeding 1000°C.

Preventing Contamination

By separating the sample from the heat source and any potential combustion, the muffle design prevents chemical contamination.

This makes it indispensable for sensitive scientific processes like ashing, where the goal is to burn off organic material to determine inorganic content, or sintering, where material purity affects the final product's structural integrity.

How Uniform Temperature is Achieved and Maintained

Achieving a consistent temperature throughout the chamber is not accidental; it is a direct result of the furnace's design and the physics of heat transfer.

Radiant and Convective Heat Transfer

Once the chamber walls are heated, they radiate thermal energy inward from all directions. This "all-around" heating is far more uniform than the intense, localized heat from a direct element.

Additionally, air inside the chamber circulates via convection, further distributing the heat and minimizing any temperature differences between the top, bottom, and center of the chamber.

The Critical Role of Outer Insulation

The ceramic muffle is wrapped in thick layers of thermal insulation. This material is designed to prevent heat from escaping into the surrounding environment.

This high-efficiency insulation is key for two reasons: it dramatically reduces energy consumption and, more importantly, it helps the temperature controller maintain a stable and precise setpoint with minimal fluctuation.

Understanding the Trade-offs

While highly effective, the muffle furnace design has inherent characteristics that are important to understand.

Slower Heating and Cooling Rates

Because the heat transfer is indirect and the chamber is heavily insulated, muffle furnaces generally take longer to heat up and cool down compared to direct-fire furnaces. This must be factored into process timing.

Potential for Thermal Shock

The ceramic muffle, while durable at high temperatures, can be susceptible to thermal shock. Opening the door at peak temperature or attempting to cool a sample too quickly can introduce stress and potentially crack the chamber material.

Making the Right Choice for Your Goal

Understanding how the chamber functions allows you to leverage its strengths for your specific thermal processing needs.

- If your primary focus is analytical purity (e.g., ashing, trace element analysis): The muffle's ability to isolate the sample from contaminants is its most valuable feature.

- If your primary focus is consistent material processing (e.g., sintering, annealing): The uniform, repeatable heating environment created by radiant heat is the key to achieving predictable results.

- If your primary focus is high throughput and speed: Acknowledge that the slower heating and cooling cycles are an inherent trade-off for the precision and purity this furnace provides.

By mastering its principles, you can transform the muffle furnace from a simple oven into a precise tool for reliable and repeatable results.

Summary Table:

| Function | Description |

|---|---|

| Isolation | Separates sample from heating elements to prevent contamination |

| Uniform Heating | Uses radiant heat from ceramic walls for even temperature distribution |

| Contamination Prevention | Shields interior from gases and particles, ideal for sensitive processes |

| Energy Efficiency | Outer insulation reduces heat loss and maintains stable temperatures |

Upgrade your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for contamination-free, uniform heating. Contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production