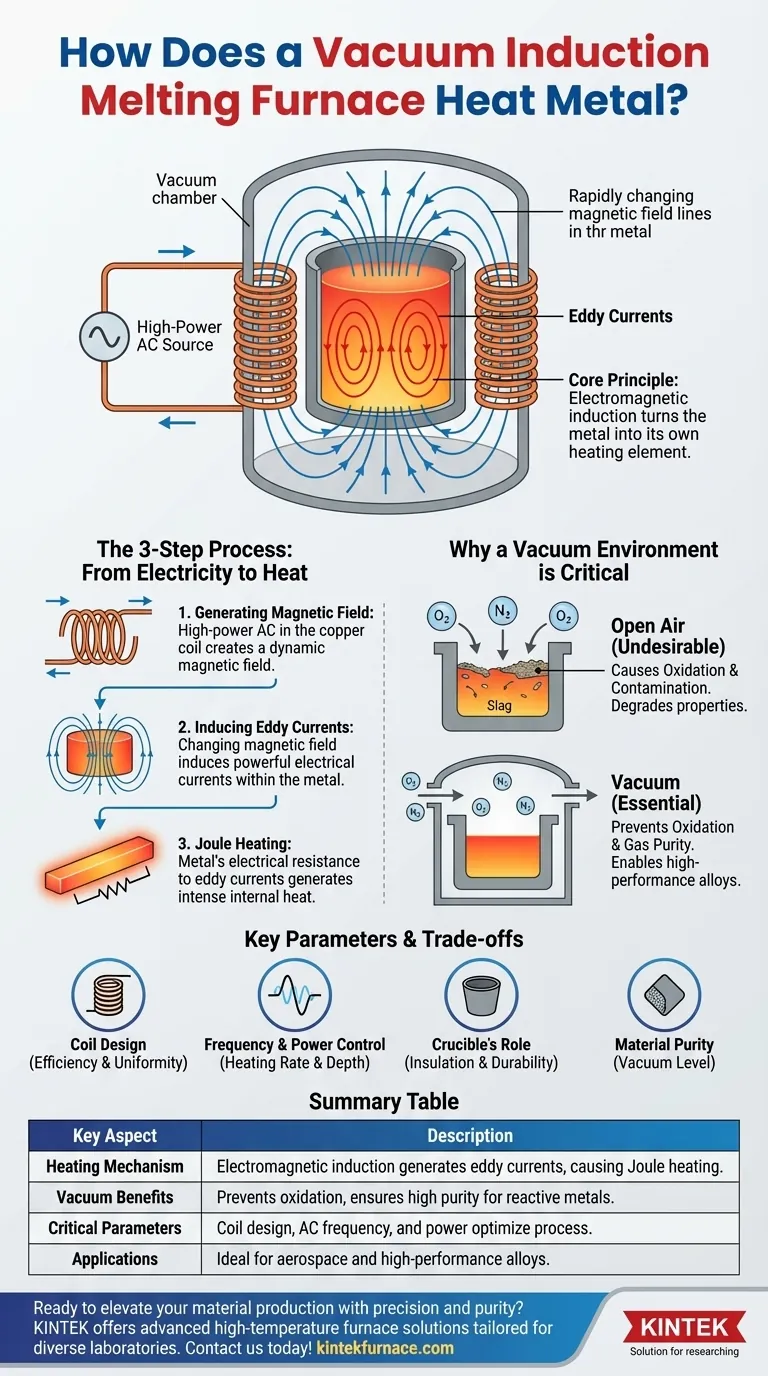

In a vacuum induction furnace, the coil heats the metal without any direct contact. It generates a powerful, rapidly changing magnetic field that penetrates the metallic charge. This field induces strong electrical currents—known as eddy currents—directly within the metal itself, and the material’s own electrical resistance to these currents causes it to rapidly heat, liquefy, and melt.

The core principle is that electromagnetic induction turns the metal into its own heating element. Combining this non-contact heating method with a vacuum environment is what allows for the production of extremely pure, reactive, and high-performance alloys, free from the contamination and oxidation that would occur in open air.

The Core Principle: From Electricity to Heat

The process of induction heating is a clean and contained energy transfer that happens in three distinct steps. It leverages fundamental laws of physics to generate heat precisely where it's needed—inside the metal.

Step 1: Generating the Magnetic Field

An induction furnace begins with a high-power alternating current (AC) source. This current is fed into a precisely wound copper coil that surrounds the crucible holding the metal.

Because the current is alternating, it continuously and rapidly changes direction. This dynamic flow of electricity generates an equally dynamic and powerful magnetic field in the space within and around the coil.

Step 2: Inducing Eddy Currents

This rapidly changing magnetic field penetrates the electrically conductive metal inside the crucible. According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any conductor within it.

These induced currents are called eddy currents. They flow in closed loops within the metal, mirroring the current flowing in the outer coil but in the opposite direction.

Step 3: Joule Heating - The Source of Heat

All metals have a natural electrical resistance. As the powerful eddy currents are forced to flow through the metal, they encounter this resistance. This opposition generates intense heat, a phenomenon known as Joule heating.

The metal effectively becomes its own heating element, heating from the inside out. The intensity of the heating is directly proportional to the square of the current, which is why high-power induction systems can melt metal so quickly.

Why a Vacuum Environment is Critical

Using induction heating inside a vacuum chamber is not an accident; it is essential for producing advanced materials. The vacuum provides benefits that are impossible to achieve in an open-atmosphere furnace.

Preventing Oxidation and Contamination

The primary function of the vacuum is to remove oxygen and other reactive atmospheric gases. Many advanced alloys and reactive metals, like titanium or superalloys, would instantly oxidize at high temperatures if exposed to air.

This oxidation creates impurities (slag) that degrade the material's mechanical properties. The vacuum ensures the final product is chemically pure and free from these oxides.

Ensuring Alloy Purity

Beyond oxidation, a vacuum removes other gases like hydrogen and nitrogen. These gases can dissolve into molten metal and create microscopic voids or undesirable compounds as the metal solidifies.

By melting in a vacuum, metallurgists can ensure the final alloy's chemical composition is precisely what was intended, with no unintended gaseous impurities.

Understanding the Trade-offs and Key Parameters

Achieving an efficient and controlled melt requires more than just turning the power on. The system's design and operating parameters are critical for success.

The Importance of Coil Design

The induction coil is not a simple component; it is a carefully engineered tool. The number of turns, its diameter, and its shape are all calculated to concentrate the magnetic field for uniform and efficient coupling with the metal charge.

A poorly designed coil can lead to inefficient energy transfer, creating hot spots in one area and leaving other parts of the charge solid.

Frequency and Power Control

The frequency of the alternating current is a key variable. Higher frequencies tend to concentrate the heating effect near the surface of the metal (a phenomenon known as the skin effect). Lower frequencies penetrate deeper into the charge.

Matching the frequency to the size and type of metal is crucial for efficient melting. The power level, meanwhile, directly dictates the rate of heating and the final temperature, giving operators precise control over the melting process.

The Crucible's Role

The crucible, which holds the molten metal, must be made from a material that can withstand extreme temperatures while also being an electrical insulator. Materials like ceramics or graphite are often used.

If the crucible were electrically conductive, the magnetic field would heat it as well, wasting energy and potentially contaminating the melt.

Making the Right Choice for Your Goal

Understanding these principles allows for better control over the melting process to achieve specific material outcomes.

- If your primary focus is material purity: The vacuum level is your most critical parameter to prevent oxidation and gas absorption in reactive metals.

- If your primary focus is melting efficiency: Coil design and the selected AC frequency are key to ensuring the magnetic field couples effectively and uniformly with the charge.

- If your primary focus is precise temperature control: Mastering the regulation of the AC power input is essential for achieving specific melt profiles and preventing the overheating of sensitive alloys.

By mastering the interplay between the electromagnetic field, the material, and the vacuum, you gain precise control over the creation of high-performance alloys.

Summary Table:

| Key Aspect | Description |

|---|---|

| Heating Mechanism | Electromagnetic induction generates eddy currents in metal, causing Joule heating from within. |

| Vacuum Benefits | Prevents oxidation and contamination, ensuring high purity for reactive metals and alloys. |

| Critical Parameters | Coil design, AC frequency, and power control optimize melting efficiency and temperature precision. |

| Applications | Ideal for producing pure, high-performance alloys in industries like aerospace and metallurgy. |

Ready to elevate your material production with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're focused on material purity, melting efficiency, or precise temperature control, our expertise ensures optimal results. Contact us today to discuss how we can support your high-performance alloy goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications