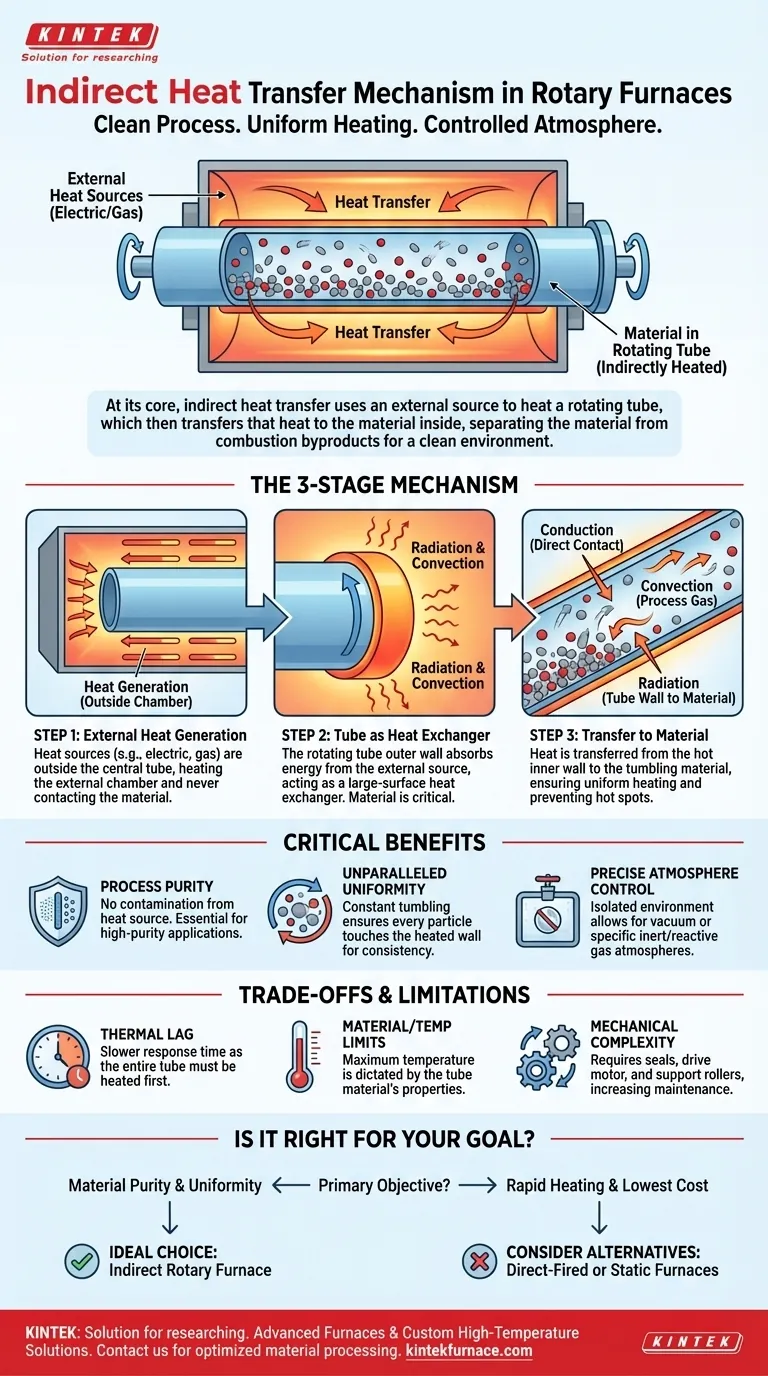

At its core, indirect heat transfer in a rotary furnace works by using an external heat source to heat a rotating tube, which then transfers that heat to the material tumbling inside it. This design intentionally separates the material from the combustion byproducts or heating elements, ensuring a clean processing environment. The rotation continuously mixes the material, guaranteeing every particle is uniformly exposed to the heated tube wall.

The fundamental advantage of this design is not just indirect heating, but the powerful combination of process purity (from separating the heat source) and thermal uniformity (from the constant rotation).

The Mechanics of Indirect Heat Transfer

To understand how a rotary furnace achieves its results, it is best to break the process down into three distinct stages of heat movement.

Step 1: External Heat Generation

The process begins with a heat source—typically electric elements or gas burners—located in a chamber outside of the central processing tube.

These sources heat the atmosphere and surfaces within the external chamber, but they never come into direct contact with the material being processed.

Step 2: The Tube as a Heat Exchanger

The rotating tube, which contains the process material, is situated inside this heated chamber. The tube's outer wall absorbs energy from the external heat source through a combination of radiation and convection.

This effectively turns the entire rotating tube into a dynamic, large-surface-area heat exchanger. The tube's material (often a specific metal alloy, quartz, or ceramic) is critical for efficient heat conduction from the outer wall to the inner wall.

Step 3: Transfer to the Material

As the tube rotates, it continuously lifts and tumbles the material inside. Heat is transferred from the hot inner wall of the tube to the material through three primary mechanisms:

- Conduction: Direct contact between material particles and the hot tube wall.

- Convection: Heat transfer through any process gas present inside the tube.

- Radiation: Heat radiating from the hot inner wall onto the surface of the material bed.

The constant mixing from the rotation is the key to ensuring uniform heating and preventing hot spots.

Why This Design is Critical for Process Control

The indirect method is chosen for specific, high-value applications where process control is paramount. The benefits go far beyond simply heating a substance.

Preventing Contamination

By keeping the combustion gases or electric elements separate from the process material, you eliminate the risk of contamination. This is non-negotiable in applications like manufacturing high-purity chemicals, battery materials, or pharmaceuticals.

Achieving Unparalleled Uniformity

In a static furnace, material at the bottom and center can remain cooler than material at the edges. The tumbling action of a rotary furnace ensures every granule or particle spends time in contact with the heated wall, resulting in exceptional batch consistency and predictable outcomes.

Enabling Precise Atmosphere Control

Because the internal process environment is isolated, it can be precisely controlled. This allows for processes that must occur under a vacuum or within a specific atmosphere of inert (e.g., nitrogen, argon) or reactive gases, without interference from external combustion products.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. An objective assessment requires understanding its inherent limitations.

Thermal Lag and Response Time

The furnace must first heat the entire mass of the rotating tube before that heat can be transferred to the material. This creates a degree of thermal lag, meaning these systems can be slower to heat up and respond to temperature changes compared to direct-fired systems.

Material and Temperature Limitations

The maximum operating temperature of the furnace is dictated by the material of the process tube. High-temperature alloys and ceramics are expensive and can be brittle, while lower-cost materials have lower temperature ceilings. The tube must also be chemically compatible with the process material.

Mechanical Complexity

The system requires a drive motor, support rollers, and, most critically, robust seals at both ends of the rotating tube. These seals must maintain atmospheric integrity while allowing for thermal expansion, adding mechanical complexity and maintenance requirements compared to a simple static furnace.

Is an Indirect Rotary Furnace Right for Your Goal?

Choosing the right thermal technology depends entirely on your primary process objective.

- If your primary focus is material purity and preventing contamination: The indirect rotary furnace is the ideal choice due to its inherent separation of the heat source and process material.

- If your primary focus is uniform processing of powders or granulars: The combination of indirect heat and constant rotation is purpose-built to deliver exceptional thermal uniformity and batch consistency.

- If your primary focus is rapid heating and the lowest equipment cost: You must evaluate if the potential for thermal lag is acceptable, and consider that direct-fired systems or static furnaces may offer a simpler, faster-responding alternative.

Ultimately, selecting this technology is a decision to prioritize process control and product quality over raw speed or simplicity.

Summary Table:

| Aspect | Key Details |

|---|---|

| Mechanism | External heat source heats rotating tube, transferring heat indirectly to material via conduction, convection, and radiation. |

| Benefits | Process purity (no contamination), thermal uniformity (from rotation), precise atmosphere control (vacuum/inert gases). |

| Limitations | Thermal lag (slower response), material/temperature constraints, mechanical complexity (seals, maintenance). |

| Ideal For | High-purity applications (e.g., chemicals, pharmaceuticals), uniform powder/granular processing, controlled atmosphere needs. |

Ready to enhance your lab's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Rotary, Muffle, Tube, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements for purity, uniformity, and efficiency. Contact us today to discuss how our solutions can optimize your material processing!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity