Ultimately, the dental furnace is the single most critical piece of equipment in determining the final quality of a ceramic restoration. Its function goes far beyond simple heating; it is a precision instrument that dictates the material's final strength, aesthetics, and fit. An inadequate furnace will consistently produce compromised results, regardless of the quality of the materials or the skill of the technician.

A high-quality dental furnace is not merely a heater but a precision-control device. Its ability to accurately manage temperature, time, and atmosphere during the sintering or firing process is what transforms raw ceramic into a durable, esthetic, and perfectly fitting restoration.

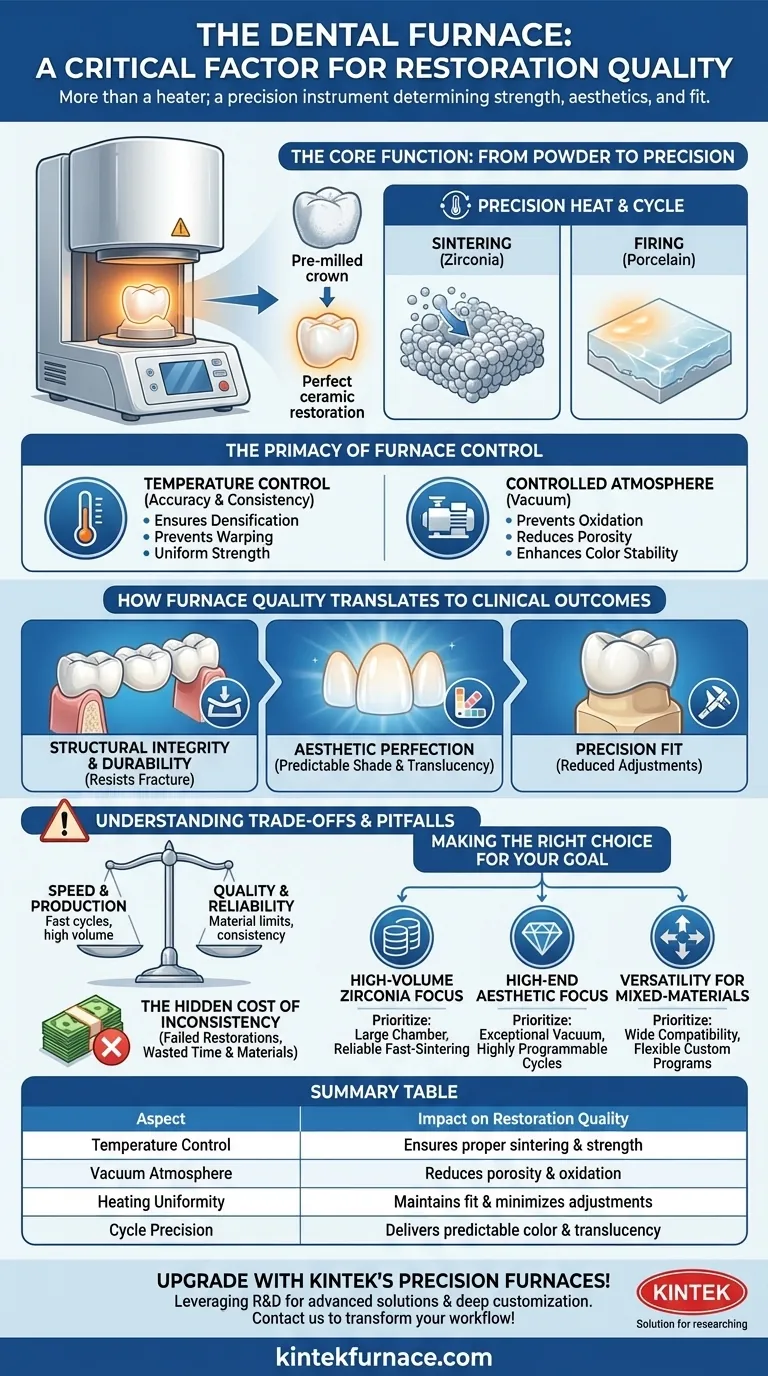

The Core Function: From Powder to Precision

To understand the furnace's impact, you must first understand the process it controls. This transformation is what turns a chalky, fragile pre-milled shape into a final, robust dental prosthesis.

What is Sintering and Firing?

Sintering is the process of using heat to fuse ceramic particles together, densifying the material without melting it. This process is primarily used for materials like zirconia.

Firing, often used for porcelain veneers, involves heating the material to vitrify it, creating a glass-like, non-porous surface. Both processes are highly sensitive to thermal variations.

The Primacy of Temperature Control

The furnace's most important job is to execute a programmed heating and cooling cycle with absolute precision. Even minor deviations can have catastrophic effects on the final restoration.

Accurate temperature ensures the ceramic reaches the exact state needed for full densification and strength. Consistent temperature throughout the chamber prevents hot or cold spots that cause warping and internal stress.

The Role of a Controlled Atmosphere

Many high-end restorations are fired in a vacuum. By removing air from the chamber, the furnace prevents oxygen from reacting with the ceramic materials.

This prevents oxidation, which can discolor the restoration and create a gray, lifeless appearance. A vacuum also helps eliminate trapped gasses, drastically reducing porosity for a stronger, more stain-resistant final product.

How Furnace Quality Translates to Clinical Outcomes

The technical precision of the furnace has a direct and measurable impact on the final product that is seated in a patient's mouth.

Structural Integrity and Durability

Proper sintering, governed by precise temperature and heating rates, is essential for the material to reach its target flexural strength. An inconsistent furnace can leave the material under-sintered, making it brittle and prone to fracture under occlusal load.

Aesthetic Perfection and Color Stability

A furnace with superior vacuum control and stable temperatures delivers predictable, vibrant aesthetics. It ensures that the shade and translucency prescribed by the dentist are the shade and translucency that the patient receives, without the dullness caused by oxidation.

Precision Fit and Reduced Adjustments

Warping is a common failure caused by uneven heating or cooling. A high-quality furnace ensures thermal uniformity, meaning the restoration shrinks predictably and fits the die perfectly. This minimizes the need for time-consuming chairside adjustments.

Understanding the Trade-offs and Common Pitfalls

Choosing a furnace involves balancing several factors. Understanding these trade-offs is key to avoiding costly mistakes.

Speed vs. Quality

Many modern furnaces offer "speed" or "fast" sintering cycles. While highly efficient for production, these cycles push materials to their thermal limits. They demand an exceptionally well-calibrated furnace to succeed without compromising the restoration's strength or aesthetics.

Workload and Capacity

Under-sizing a furnace for your lab's volume creates bottlenecks and may force you to run it constantly, increasing wear. Over-sizing can be inefficient. Analyze your current and projected daily output before investing.

The Hidden Cost of Inconsistency

A cheaper, less reliable furnace is one of the most expensive purchases a lab can make. The cost of failed restorations—in wasted materials, technician time, and dentist chair time—quickly eclipses any initial savings. Consistency is the primary marker of a furnace's value.

Making the Right Choice for Your Goal

Your choice should be guided by the primary type of work you perform. There is no single "best" furnace, only the best furnace for a specific application.

- If your primary focus is high-volume zirconia production: Prioritize a furnace with a large chamber, proven reliability, and well-tested fast-sintering cycles to maximize throughput.

- If your primary focus is high-end, aesthetic anterior cases: Choose a furnace with exceptional vacuum control and highly programmable firing cycles for superior porcelain handling and color stability.

- If your primary focus is versatility for a mixed-materials lab: Select a furnace that is compatible with a wide range of ceramics and offers the flexibility to easily create and store custom programs for each one.

Investing in the right furnace is an investment in predictable outcomes, clinical excellence, and long-term operational efficiency.

Summary Table:

| Aspect | Impact on Restoration Quality |

|---|---|

| Temperature Control | Ensures proper sintering for strength and prevents warping |

| Vacuum Atmosphere | Reduces porosity and oxidation for better aesthetics and durability |

| Heating Uniformity | Maintains consistent fit and minimizes adjustments |

| Cycle Precision | Delivers predictable results for color and translucency |

Upgrade your dental lab with KINTEK's precision furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met, enhancing restoration quality and lab efficiency. Contact us today to discuss how our furnaces can transform your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow