Plasma-Enhanced Chemical Vapor Deposition (PECVD) achieves its efficiency by fundamentally changing how energy is delivered to the chemical reaction. Instead of using high heat to break down gases, it uses an electric field to create a plasma, providing the necessary energy at significantly lower temperatures. This plasma-based process is inherently more controllable, leading to high stability and uniform film quality.

The core advantage of PECVD is its strategic shift from brute-force thermal energy to precisely controlled plasma energy. This not only dramatically reduces energy consumption but also creates a stable, diffusive environment ideal for depositing high-quality, uniform thin films.

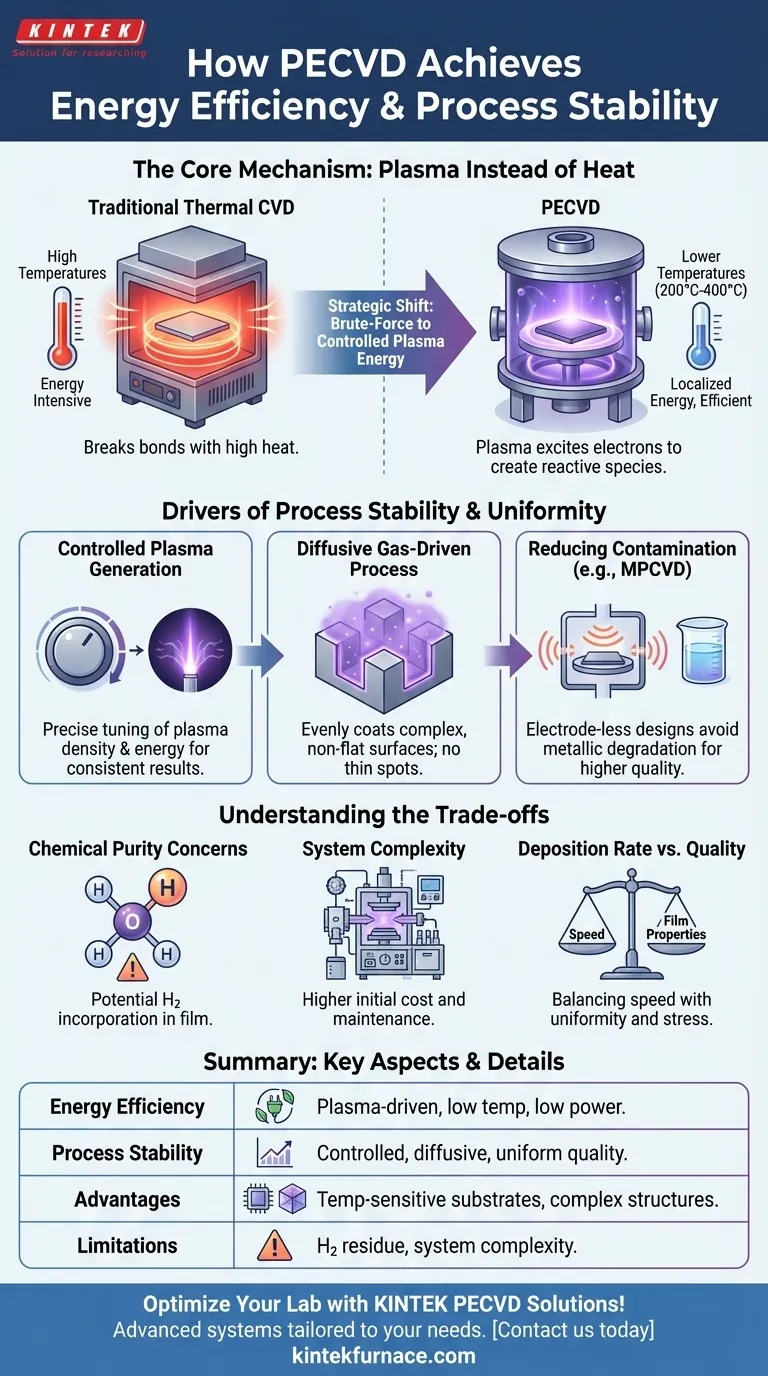

The Core Mechanism: Plasma Instead of Heat

The primary source of PECVD's energy efficiency is its ability to bypass the high-temperature requirements of traditional Chemical Vapor Deposition (CVD).

How Plasma Replaces Thermal Energy

Traditional thermal CVD requires very high temperatures to provide enough energy to break the chemical bonds of precursor gases.

PECVD accomplishes the same goal by using plasma. This allows for high-quality film deposition at much lower temperatures, typically in the 200°C to 400°C range, making it suitable for substrates that cannot withstand high heat.

Creating Reactive Species at Low Temperatures

Inside the PECVD vacuum chamber, an electric or magnetic field is applied to a mixture of precursor gases (like silane) and inert gases.

This field excites electrons, which then collide with the neutral gas molecules. These high-energy collisions, occurring at energies of 100-300 eV, create a plasma filled with ions and other reactive species that are ready to form a film.

The Impact on Energy Consumption

Heating a large vacuum chamber and substrate to the high temperatures required by thermal CVD is extremely energy-intensive.

By using plasma to drive the reaction, PECVD localizes the energy delivery directly to the gases, dramatically lowering the overall temperature and power requirements of the system.

Drivers of Process Stability and Uniformity

PECVD's stability isn't a side effect; it's a direct result of how the plasma process is controlled and how the reactive gases behave.

Controlled Plasma Generation

The deposition process is not a blunt instrument. Operators can precisely tune the plasma density and energy by adjusting the applied electric or magnetic field.

This control allows for fine-tuning of the film's growth rate, microstructure, and final properties, ensuring consistent results from one run to the next.

Diffusive Gas-Driven Process

Unlike line-of-sight processes like Physical Vapor Deposition (PVD), PECVD is diffusive. The plasma and reactive gas species flow and surround the substrate.

This characteristic is a major advantage for stability and uniformity, as it allows the process to evenly coat complex, non-flat surfaces, such as trenches and 3D structures, without creating thin spots or gaps.

Reducing Contamination for Higher Quality

Advanced PECVD techniques, such as Microwave Plasma CVD (MPCVD), further enhance stability by using electrode-less designs.

By generating the plasma with microwaves, these systems avoid the use of internal metal electrodes, which can degrade and introduce metallic contamination into the film. This results in a purer, more stable deposition.

Understanding the Trade-offs

While powerful, PECVD is not without its considerations. Objectivity requires acknowledging its limitations.

Chemical Purity Concerns

Because PECVD is a "chemical" process that breaks down molecules like silane (SiH4), byproducts such as hydrogen can become incorporated into the deposited film. For some highly sensitive electronic or optical applications, this can be an undesirable impurity.

System Complexity

A PECVD system involves a sophisticated combination of components: a vacuum chamber, high-power RF or microwave generators, gas handling systems, and pressure controllers. This complexity can translate to higher initial equipment costs and maintenance compared to simpler thermal systems.

Deposition Rate vs. Quality

There is often a trade-off between the speed of deposition and the quality of the film. While the process parameters are highly controllable, pushing for a very high deposition rate can sometimes compromise film density, uniformity, or stress levels, requiring careful optimization.

Making the Right Choice for Your Application

Selecting the right deposition method requires aligning its strengths with your project's primary goal.

- If your primary focus is energy efficiency and depositing on temperature-sensitive substrates: PECVD is the superior choice due to its low-temperature operation.

- If your primary focus is achieving uniform coverage on complex 3D structures: PECVD's diffusive nature offers significant advantages over line-of-sight methods like PVD.

- If your primary focus is the absolute highest film purity with no chemical residue: You must consider potential hydrogen incorporation and evaluate if other methods are a better fit for your specific material requirements.

Ultimately, understanding PECVD's reliance on plasma energy empowers you to leverage its unique balance of efficiency, stability, and versatility.

Summary Table:

| Aspect | Key Details |

|---|---|

| Energy Efficiency | Uses plasma instead of high heat, reducing temperatures to 200°C-400°C and lowering power consumption. |

| Process Stability | Controlled plasma generation and diffusive gas flow ensure uniform film quality and consistent results. |

| Advantages | Suitable for temperature-sensitive substrates, covers complex 3D structures, and reduces contamination risks. |

| Limitations | Potential hydrogen incorporation, higher system complexity, and trade-offs in deposition rate vs. quality. |

Optimize your lab's thin film deposition with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD, tailored to your unique experimental needs. Our deep customization capabilities ensure precise performance for energy-efficient, stable processes. Contact us today to discuss how our solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures