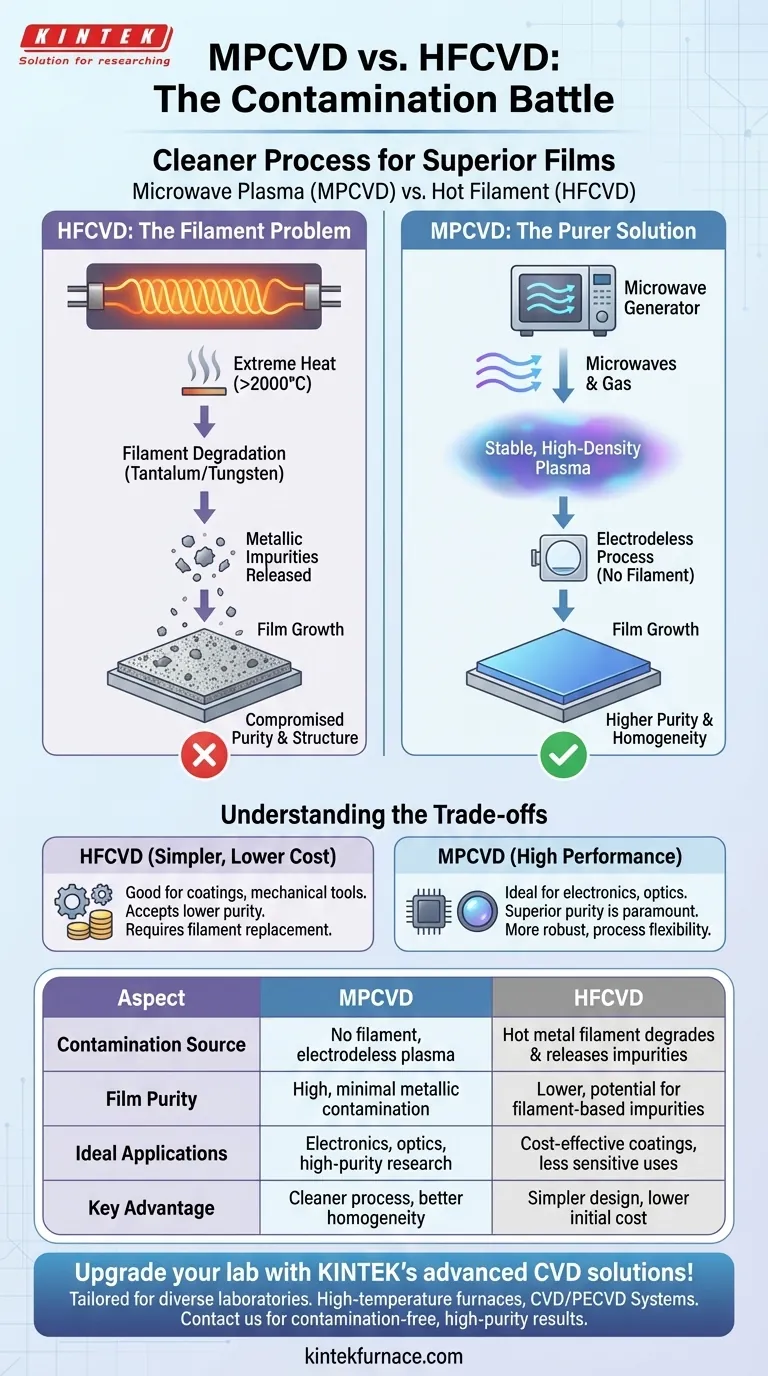

In a direct comparison, MPCVD is an inherently cleaner process than HFCVD. The fundamental difference lies in how each method generates the energy needed for chemical vapor deposition. MPCVD uses microwaves to create a plasma, completely avoiding the primary source of contamination in HFCVD: a hot metal filament that degrades over time.

The core issue is simple: Hot Filament CVD (HFCVD) introduces a potential contaminant—the filament itself—into the growth chamber. Microwave Plasma CVD (MPCVD) eliminates this variable entirely, resulting in a fundamentally purer deposition environment and higher-quality films.

The Source of Contamination in HFCVD

The defining feature of Hot Filament CVD is also its greatest weakness regarding contamination. The process relies on a physical wire heated to extreme temperatures to break down precursor gases.

The Role of the Hot Filament

HFCVD systems use a filament, typically made of tantalum or tungsten, heated to over 2000°C. This intense heat provides the energy to dissociate the reactant gases (like methane and hydrogen) and create the reactive species needed for film growth.

How Filament Degradation Occurs

Over time, these hot wires are exposed to a harsh environment of reactive gases. This causes the filament material to degrade, evaporate, and carburize, slowly breaking down.

The Impact of Metallic Impurities

As the filament degrades, atoms of tantalum or tungsten are released into the chamber. These metal atoms can then become incorporated into the growing film—for example, a diamond film—as unwanted impurities. This contamination compromises the film's purity and structural integrity.

How MPCVD Achieves Higher Purity

MPCVD sidesteps the filament problem by using a different energy source. This "electrodeless" approach is central to its ability to produce exceptionally pure materials.

The Electrodeless Plasma Method

MPCVD uses microwaves to energize the gas inside the chamber, creating a stable, high-density plasma. Because there is no internal electrode or filament, there is no component inside the reaction zone that can degrade and contaminate the film.

Greater Process Control and Homogeneity

The plasma generated by MPCVD provides a high density of reactive species in a more controlled and uniform manner. This leads to better homogeneity across the entire deposition area, ensuring consistent film quality over large surfaces.

Flexibility with Reactive Gases

The absence of a sensitive filament makes MPCVD more robust. Filaments in HFCVD can be highly sensitive to certain gases, limiting the types of precursors you can use and affecting the filament's lifespan. MPCVD allows for a wider range of process gases, enabling more versatile applications.

Understanding the Trade-offs

While MPCVD offers superior purity, the choice of a CVD method is not always straightforward. The decision often involves balancing performance requirements with practical constraints.

Why Purity Directly Affects Film Quality

For high-performance applications, such as electronics or optics, material purity is paramount. The metallic contamination from HFCVD can negatively affect the diamond's thermal, optical, or electronic properties. MPCVD's ability to produce higher-purity films makes it the preferred method for these demanding fields.

The Cost and Complexity Factor

Generally, HFCVD systems are simpler in design and less expensive to build and operate than MPCVD systems. The recurring cost in HFCVD comes from replacing degraded filaments, which can also lead to process downtime.

When HFCVD Might Be Sufficient

For applications where absolute purity is not the primary driver, HFCVD can be a perfectly viable and cost-effective solution. This includes coatings for mechanical tools or other areas where minor impurities do not significantly impact performance.

Making the Right Choice for Your Application

Your final decision should be guided by the specific quality and performance requirements of your project.

- If your primary focus is maximum purity and performance: Choose MPCVD. Its electrodeless nature guarantees a cleaner process and a higher-quality film, which is essential for electronics, optics, and research-grade materials.

- If your primary focus is cost-effectiveness for less sensitive applications: HFCVD can be a suitable choice. Be prepared to manage filament degradation and accept a lower level of film purity.

Ultimately, understanding the inherent contamination risk in HFCVD empowers you to select the process that best aligns with your technical and budgetary goals.

Summary Table:

| Aspect | MPCVD | HFCVD |

|---|---|---|

| Contamination Source | No filament, electrodeless plasma | Hot metal filament degrades and releases impurities |

| Film Purity | High, minimal metallic contamination | Lower, potential for filament-based impurities |

| Ideal Applications | Electronics, optics, high-purity research | Cost-effective coatings, less sensitive uses |

| Key Advantage | Cleaner process, better homogeneity | Simpler design, lower initial cost |

Upgrade your lab with KINTEK's advanced CVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like CVD/PECVD Systems tailored for diverse laboratories. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering contamination-free, high-purity results for applications in electronics, optics, and beyond. Contact us today to discuss how our MPCVD and other furnace technologies can enhance your research and production efficiency!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What role does gas flow rate play in MPCVD? Mastering Deposition Rate and Film Uniformity