In short, IGBT technology fundamentally enhances channel induction furnaces by replacing older, less efficient power supplies with a modern, digitally controlled system. This upgrade provides superior energy efficiency, far more precise control over the melting process, and reduced overall power consumption. The result is a direct increase in production rates, improved metallurgical quality, and significant long-term cost savings.

The core advantage of IGBTs over legacy technologies like thyristors is their ability to switch power at very high frequencies. This rapid, precise control is the foundational reason for nearly every performance benefit, from saving energy to improving the final metal product.

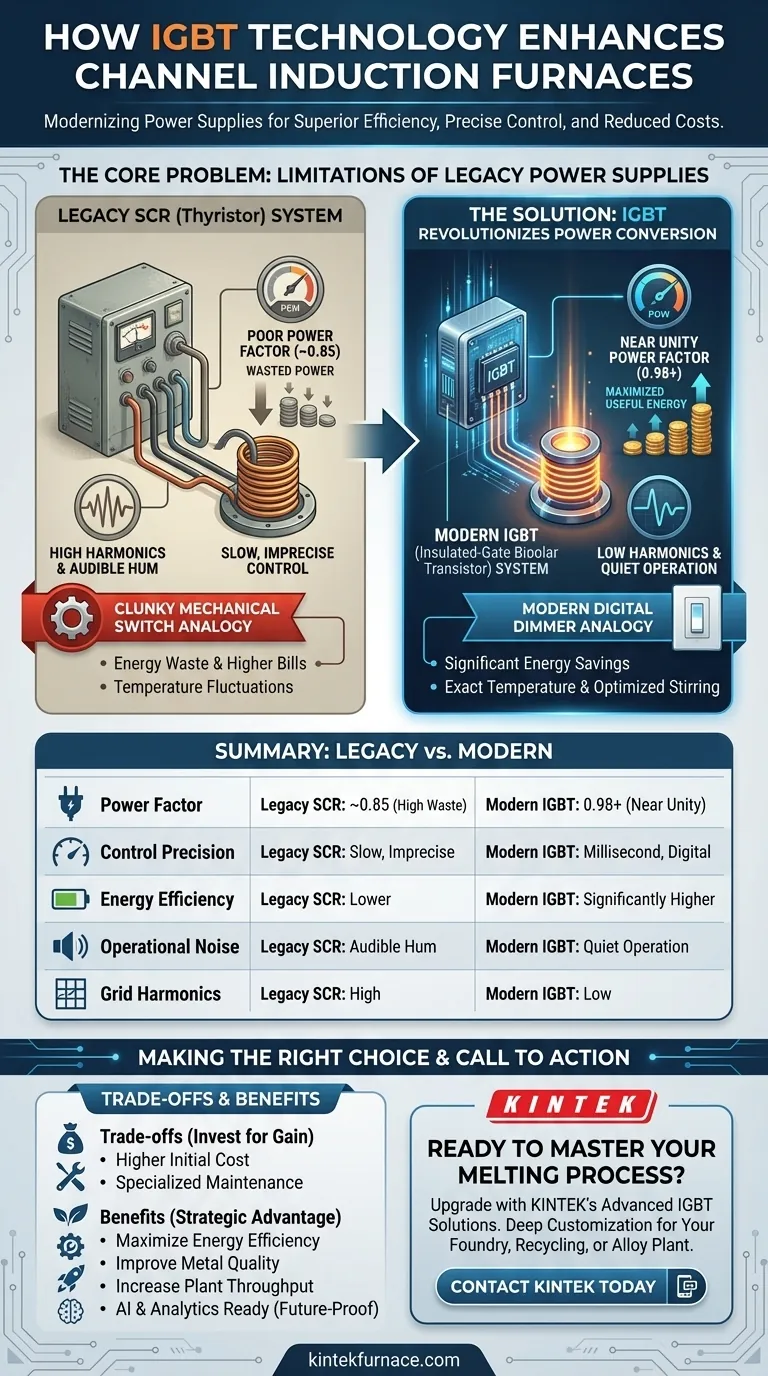

The Core Problem: Limitations of Legacy Power Supplies

To understand the impact of IGBTs, we must first look at the challenges posed by older power conversion systems, which were typically based on thyristors or Silicon-Controlled Rectifiers (SCRs).

The Challenge of Power Factor

Legacy SCR systems are known for having a poor power factor, often around 0.85. This means a significant portion of the electrical energy drawn from the grid is not converted into useful heat in the furnace, leading to wasted power and higher electricity bills.

Imprecise and Slow Control

Thyristor-based systems have a relatively slow response time. They cannot adjust power output quickly enough to react to the dynamic changes within the molten metal bath, leading to temperature fluctuations and less-than-optimal melting conditions.

Audible Noise and Harmonics

A common characteristic of older SCR-powered furnaces is a loud, audible hum during operation. Furthermore, these systems introduce significant electrical "noise" or harmonics back into the facility's power grid, which can interfere with other sensitive equipment.

How IGBTs Revolutionize Power Conversion

An Insulated-Gate Bipolar Transistor (IGBT) is a sophisticated semiconductor that acts as a high-speed switch. IGBT-based power supplies leverage this capability to overcome the limitations of older technology.

The Principle of High-Frequency Switching

Think of a thyristor as a clunky mechanical switch and an IGBT as a modern digital dimmer. IGBTs can turn on and off tens of thousands of times per second, allowing them to precisely shape the electrical waveform delivered to the furnace's induction coil.

Achieving Unity Power Factor

This high-frequency control allows the power supply to actively correct its power factor, bringing it to 0.98 or higher. This means nearly all the electricity drawn from the grid is converted into useful work, drastically reducing energy waste and lowering operational costs.

Enabling Precise Power Modulation

With IGBTs, power can be adjusted in milliseconds. This allows the furnace's control system to maintain an exact temperature, optimize the stirring action of the molten metal, and respond instantly to changes in the furnace load. This level of digital control also creates the foundation for advanced AI-driven process optimization.

Understanding the Trade-offs

While the benefits are substantial, adopting IGBT technology involves clear trade-offs that must be considered for any upgrade or new installation.

Higher Initial Cost

IGBT power supplies are more technologically advanced and, as a result, have a higher initial capital cost compared to traditional thyristor-based systems. This investment is typically justified by long-term energy savings and productivity gains.

System Complexity

These are sophisticated electronic systems. Troubleshooting and maintenance require personnel with specialized training in power electronics, which may differ from the skill set needed for older, simpler SCR systems.

Sensitivity to Grid Quality

Like most advanced electronics, IGBT systems can be more sensitive to power quality issues such as voltage spikes or sags from the electrical grid. Proper line filtering and protection are essential for ensuring long-term reliability.

Making the Right Choice for Your Goal

Evaluating an IGBT upgrade depends entirely on your operational priorities.

- If your primary focus is maximizing energy efficiency: The near-unity power factor of an IGBT system offers the single largest opportunity to reduce furnace-related electricity costs.

- If your primary focus is improving metal quality: The precise and rapid power control from an IGBT allows for exceptional temperature stability and optimized stirring, leading to more consistent and higher-quality melts.

- If your primary focus is increasing plant throughput: Faster, more efficient melting cycles and the potential for higher power density in IGBT systems directly contribute to increased production rates.

- If your primary focus is modernizing for the future: IGBT controls provide the digital platform necessary to integrate advanced process monitoring, data analytics, and AI-driven optimization.

Ultimately, adopting IGBT technology is a strategic move from simply managing furnace power to truly mastering it.

Summary Table:

| Aspect | Legacy SCR Systems | Modern IGBT Systems |

|---|---|---|

| Power Factor | ~0.85 (High Energy Waste) | 0.98+ (Near Unity) |

| Control Precision | Slow, Imprecise | Millisecond, Digital |

| Energy Efficiency | Lower | Significantly Higher |

| Operational Noise | Audible Hum | Quiet Operation |

| Grid Harmonics | High | Low |

Ready to Master Your Melting Process?

Upgrade your channel induction furnace with KINTEK's advanced IGBT-based solutions. Leveraging our exceptional R&D and in-house manufacturing, we provide robust, high-efficiency power supplies tailored to your specific needs. Our technology delivers:

- Significant Energy Savings with near-unity power factor.

- Unmatched Process Control for superior metallurgical quality.

- Increased Production Rates through faster, more efficient melting.

Whether you operate a foundry, a metal recycling plant, or a specialized alloy producer, KINTEK's deep customization capabilities ensure a perfect fit for your unique requirements.

Contact KINTEK today to discuss how our IGBT technology can transform your furnace performance and profitability.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency