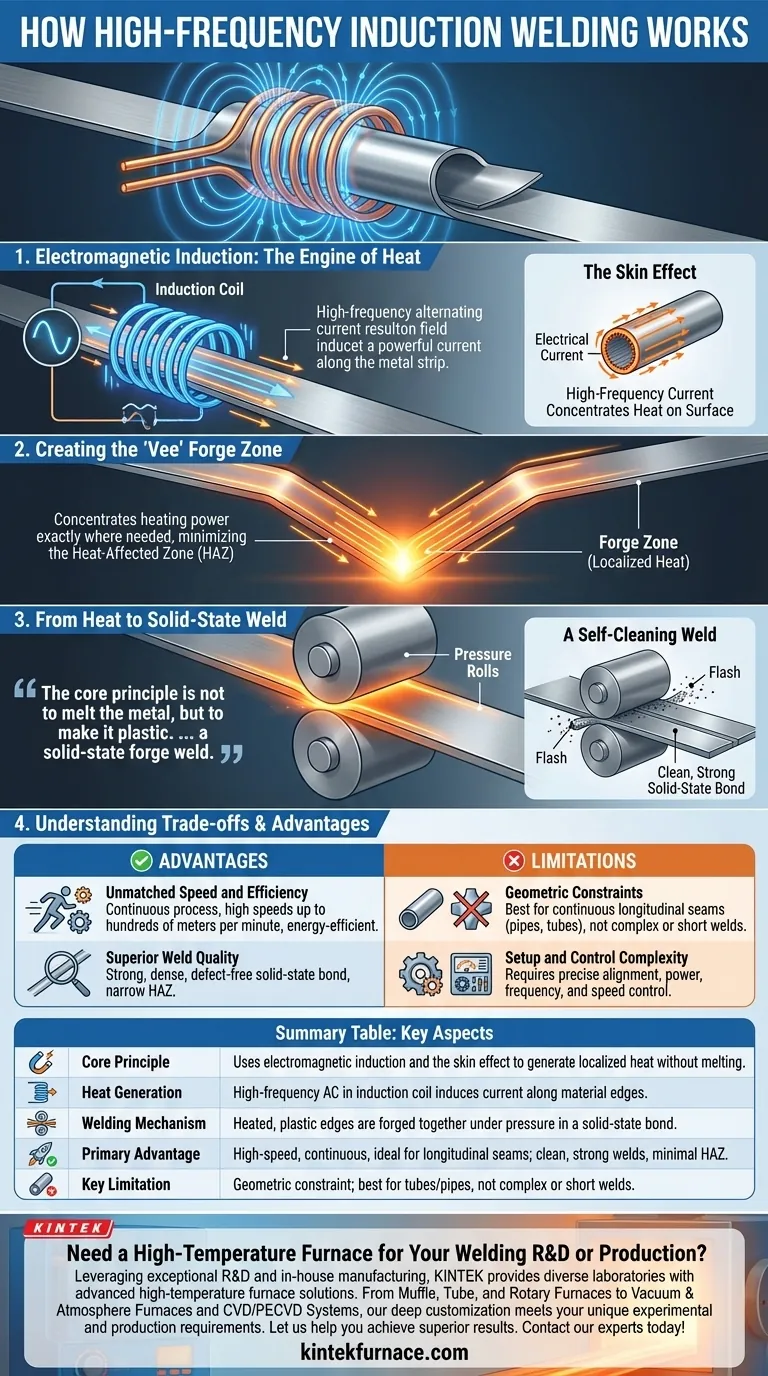

High-frequency (HF) induction welding uses electromagnetic principles to generate intense, localized heat directly within the material being joined. An induction coil creates a high-frequency magnetic field, which induces a powerful electrical current along the edges of the metal strips. This current rapidly heats the edges to a forging temperature just below their melting point, after which they are pressed together by rollers to form a clean, strong, solid-state weld.

The core principle is not to melt the metal, but to make it plastic. High-frequency current concentrates heat in a very thin layer at the joining edges, allowing them to be forged together under pressure in a continuous, high-speed process that expels impurities.

The Physics of High-Frequency Heating

At the heart of this process are two fundamental physical principles working in tandem: electromagnetic induction and the skin effect. Understanding these is key to understanding the efficiency and precision of HF welding.

Electromagnetic Induction: The Engine of Heat

Electromagnetic induction is the process where a changing magnetic field in a conductor induces an electrical current.

In HF welding, a specially designed induction coil is placed around the material. A high-frequency alternating current (AC) is passed through this coil, which generates a powerful and rapidly changing magnetic field.

This magnetic field, in turn, induces a significant current to flow within the metal itself, specifically along the path of least impedance—the edges of the seam.

The Critical Role of High Frequency (The Skin Effect)

The "high-frequency" aspect is what makes the process so precise. At high frequencies, electrical current does not flow uniformly through a conductor; it concentrates on its outer surface.

This phenomenon is known as the skin effect. It forces the induced current into a very thin layer along the edges of the seam that are about to be joined.

This concentrates the heating power exactly where it is needed and nowhere else, making the process incredibly fast and energy-efficient while minimizing the heat-affected zone (HAZ).

Creating the "Vee" Forge Zone

As the formed metal (like an open tube) travels toward the welding point, the edges form a "V" shape as they converge.

The induced current travels down one edge of this "Vee" and back up the other, creating an extremely hot point where the two edges finally meet. This is the forge zone.

From Heat to a Solid-State Weld

Heating is only the first half of the process. The second, equally critical part is the mechanical forging that creates the final bond.

Reaching Forging Temperature, Not Melting Point

A crucial distinction of HF induction welding is that it is a solid-state forge weld, not a fusion weld.

The metal edges are heated until they become soft and plastic, but they do not turn into a liquid. This avoids many problems associated with melting and resolidifying, such as porosity and brittleness.

The Function of Pressure Rolls

Immediately after the edges reach the optimal forging temperature, they pass through a set of high-pressure squeeze rolls.

These rollers physically press the hot, plastic edges together with immense force. This action forges the two surfaces into a single, homogenous structure.

A Self-Cleaning Weld

The pressure from the rolls serves a dual purpose. Not only does it forge the metal, but it also squeezes out any oxides, scale, and other impurities that may have formed on the surface.

This material is expelled from the joint as a small bead (or "flash") on the inside and outside of the weld, which can be trimmed off. The result is an exceptionally clean and pure weld line.

Understanding the Trade-offs and Advantages

HF induction welding is a dominant process in specific applications, but its strengths come with inherent limitations.

Advantage: Unmatched Speed and Efficiency

For continuous applications like manufacturing pipe and tube, HF welding is extraordinarily fast, with speeds reaching hundreds of meters per minute. The localized heating makes it highly energy-efficient compared to processes that must heat the entire bulk material.

Advantage: Superior Weld Quality

The solid-state nature of the weld, combined with the self-cleaning action of the squeeze rolls, produces a bond that is strong, dense, and free of defects. The very narrow heat-affected zone maintains the mechanical properties of the parent material.

Limitation: Geometric Constraints

The primary limitation of HF welding is its geometry. It is almost exclusively used for producing continuous, longitudinal seams in products like tubes, pipes, and structural beams. It is not suitable for complex joints or short, individual welds.

Limitation: Setup and Control Complexity

The process requires precise alignment of the induction coil, the material, and the squeeze rolls. Power, frequency, and line speed must be tightly controlled to ensure a consistent, high-quality weld, demanding sophisticated control systems and skilled setup.

Making the Right Choice for Your Goal

Deciding if HF induction welding is the appropriate method depends entirely on the manufacturing objective.

- If your primary focus is high-volume production of tubes, pipes, or profiles: HF induction welding is the global industry standard for its unparalleled speed, reliability, and cost-effectiveness.

- If your primary focus is weld purity and minimal material degradation: The solid-state, self-cleaning nature of the process offers a significant quality advantage over fusion-based methods.

- If your primary focus is joining complex, non-linear, or one-off assemblies: This process is unsuitable; you should consider methods with greater geometric flexibility, such as TIG, MIG, or laser welding.

By mastering the interplay of high-frequency physics and mechanical force, HF induction welding provides a powerful solution for modern, high-speed manufacturing.

Summary Table:

| Key Aspect | How It Works in HF Induction Welding |

|---|---|

| Core Principle | Uses electromagnetic induction and the skin effect to generate localized heat without melting the metal. |

| Heat Generation | A high-frequency AC current in an induction coil creates a magnetic field, inducing a current along the material's edges. |

| Welding Mechanism | Heated, plastic edges are forged together under high pressure from squeeze rolls in a solid-state bond. |

| Primary Advantage | High-speed, continuous process ideal for longitudinal seams; produces clean, strong welds with a minimal heat-affected zone. |

| Key Limitation | Geometric constraint: best suited for continuous products like tubes and pipes, not for complex or short welds. |

Need a High-Temperature Furnace for Your Welding R&D or Production?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Whether you are developing new welding techniques or require precise heat treatment for materials, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Let us help you achieve superior results. Contact our experts today to discuss your specific needs!

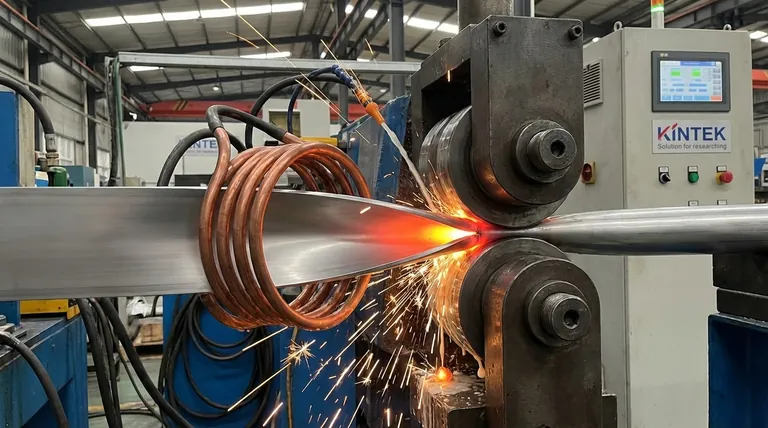

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure