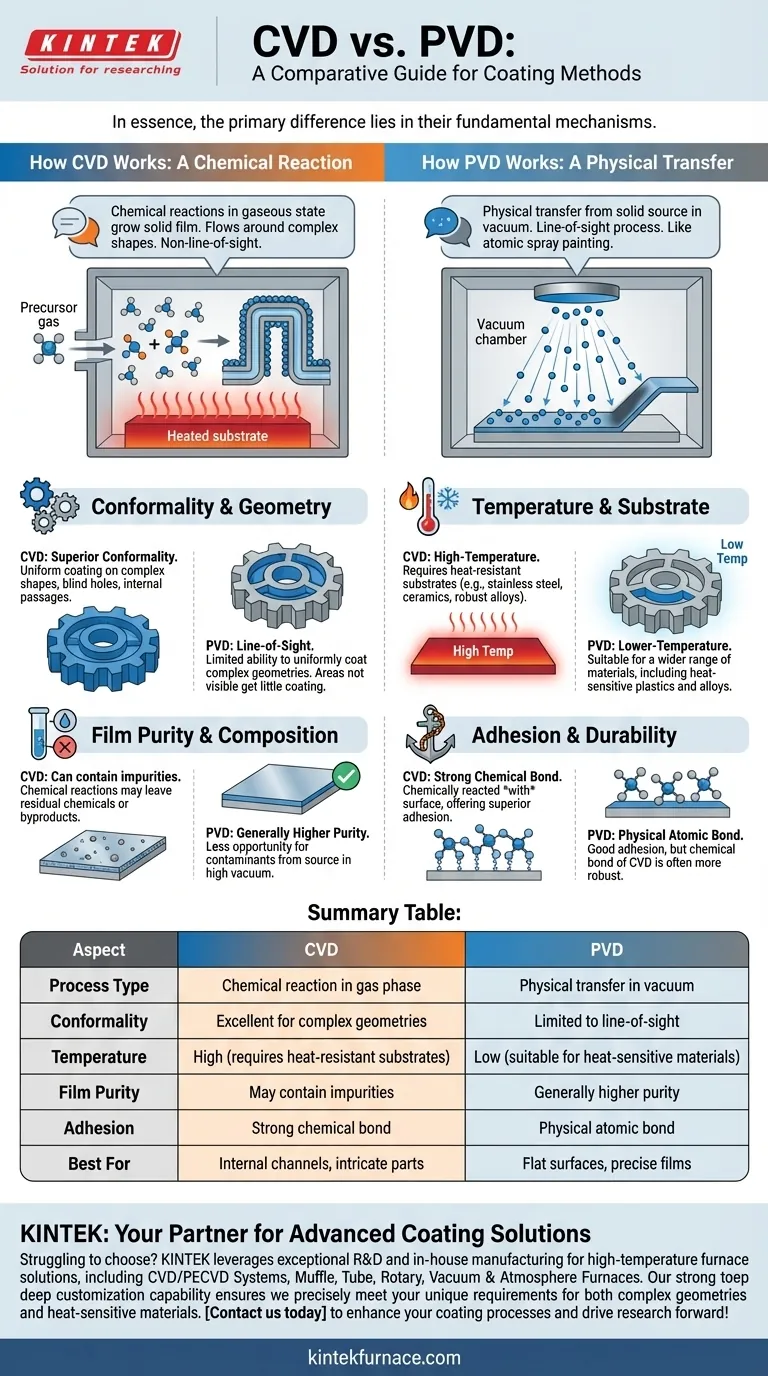

In essence, the primary difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in their fundamental mechanisms. CVD uses chemical reactions in a gaseous state to grow a solid film on a heated surface, allowing the coating to "flow" into and around complex shapes. In contrast, PVD is a physical, line-of-sight process that transfers material from a solid source to a substrate in a vacuum, similar to spray painting on an atomic level.

The choice between CVD and PVD is not about which is "better," but which is appropriate for the task. CVD excels at uniformly coating complex, heat-resistant parts via a chemical reaction, while PVD offers a lower-temperature method for depositing exceptionally pure films on surfaces within its line of sight.

The Fundamental Process: Chemical vs. Physical

The core distinction that drives all other differences between these two methods is how the coating material arrives and forms on the part's surface, also known as the substrate.

How CVD Works: A Chemical Reaction

CVD is a process where volatile precursor gases are introduced into a reaction chamber containing a heated substrate.

The high temperature provides the energy needed to trigger a chemical reaction among the gases. This reaction produces a new, solid material that deposits onto the substrate, forming a thin film.

Because this occurs in a gaseous state, the coating can permeate the entire chamber, uniformly covering all exposed surfaces, including complex internal channels and intricate geometries. It is not limited by line of sight.

How PVD Works: A Physical Transfer

PVD encompasses a family of vacuum deposition methods where a solid or liquid source material is vaporized and then transported to the substrate.

This is a physical process—no chemical reactions are intended to form the film. Material is ejected from a source (the "target") and travels in a straight line until it impacts the substrate, where it condenses back into a solid film.

This line-of-sight nature means PVD is excellent for coating flat or gently curved surfaces but struggles to coat undercuts, sharp corners, or the inside of a narrow tube.

Key Differentiators in Performance

Understanding the process difference helps explain the practical outcomes for your part. The decision to use CVD or PVD hinges on these key performance characteristics.

Conformality and Geometry

CVD has superior conformality. Because it relies on a gas-phase reaction, it can produce a highly uniform coating thickness on parts with extremely complex shapes, blind holes, and internal passages.

PVD is a line-of-sight process. This limits its ability to uniformly coat complex geometries. Areas not directly "visible" to the source material will receive little to no coating.

Temperature and Substrate Compatibility

PVD is a lower-temperature process. This makes it suitable for a wider range of materials, including temperature-sensitive plastics, certain alloys, and other substrates that would be damaged by high heat.

CVD is a high-temperature process. The heat is necessary to drive the chemical reaction. This limits its use to substrates that can withstand these elevated temperatures, such as stainless steel, ceramics, and certain robust alloys.

Film Purity and Composition

PVD generally produces higher-purity films. Since it is a physical transfer of a known source material in a high vacuum, there is less opportunity for contaminants or byproducts to be incorporated into the film. This allows for precise control over the coating's properties.

CVD films can contain impurities. The chemical reactions can sometimes be incomplete or have side reactions, potentially leaving residual chemicals or byproducts in the final coating.

Adhesion and Durability

CVD creates a strong, chemical bond. The coating is not just sitting on the surface; it is chemically reacted with the surface. This typically results in superior adhesion.

PVD films adhere through atomic bonding, but it is a physical bond. While PVD adhesion is very good for most applications, the chemical bond formed by CVD is often considered more robust.

Understanding the Trade-offs and Limitations

No process is perfect. Choosing correctly means being aware of the inherent compromises of each method.

The High-Temperature Constraint of CVD

The primary drawback of CVD is its reliance on high temperatures. This immediately disqualifies many materials and can alter the properties of the substrate itself.

The Line-of-Sight Limitation of PVD

For PVD, the main limitation is geometry. If you need to coat the inside of a component or a part with deep, narrow features, PVD is often not a viable option without complex and costly part rotation mechanisms.

Process Complexity and Safety

CVD processes can be more complex, involving the management of reactive, and sometimes hazardous, precursor gases. This requires stringent safety protocols. PVD is mechanically simpler and generally presents fewer chemical hazards.

Masking and Selective Coating

It is very difficult to mask areas on a part to prevent coating during a CVD process, as the reactive gas will penetrate nearly everywhere. PVD, being line-of-sight, is much easier to mask for selective coating.

Making the Right Choice for Your Application

Your specific goal will dictate the optimal coating technology. Use these guidelines to make a clear-headed decision.

- If your primary focus is coating complex internal geometries: CVD is the correct choice due to its non-line-of-sight nature and excellent conformality.

- If your primary focus is coating heat-sensitive materials: PVD is the necessary choice because it operates at significantly lower temperatures.

- If your primary focus is achieving the highest possible film purity: PVD offers more precise control and a cleaner deposition environment.

- If your primary focus is creating the strongest possible chemical bond to a heat-resistant substrate: CVD provides superior adhesion through its chemical reaction with the surface.

By understanding these core principles, you can confidently select the deposition method that aligns perfectly with your engineering goals.

Summary Table:

| Aspect | CVD | PVD |

|---|---|---|

| Process Type | Chemical reaction in gas phase | Physical transfer in vacuum |

| Conformality | Excellent for complex geometries | Limited to line-of-sight |

| Temperature | High (requires heat-resistant substrates) | Low (suitable for heat-sensitive materials) |

| Film Purity | May contain impurities | Generally higher purity |

| Adhesion | Strong chemical bond | Physical atomic bond |

| Best For | Internal channels, intricate parts | Flat surfaces, precise films |

Struggling to choose between CVD and PVD for your lab's coating needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you're working with complex geometries or heat-sensitive materials. Contact us today to discuss how our tailored solutions can enhance your coating processes and drive your research forward!

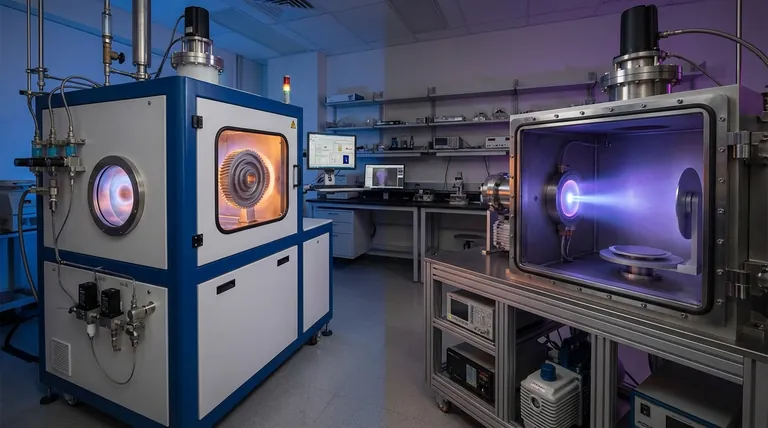

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition