At its core, a vertical tube furnace achieves its energy efficiency through a systematic design that minimizes heat loss, maximizes useful heat transfer, and optimizes energy consumption through precise control. Key elements include advanced insulation materials like alumina polycrystalline fibers, designs that promote rapid and uniform heating, and sophisticated control systems that prevent energy waste.

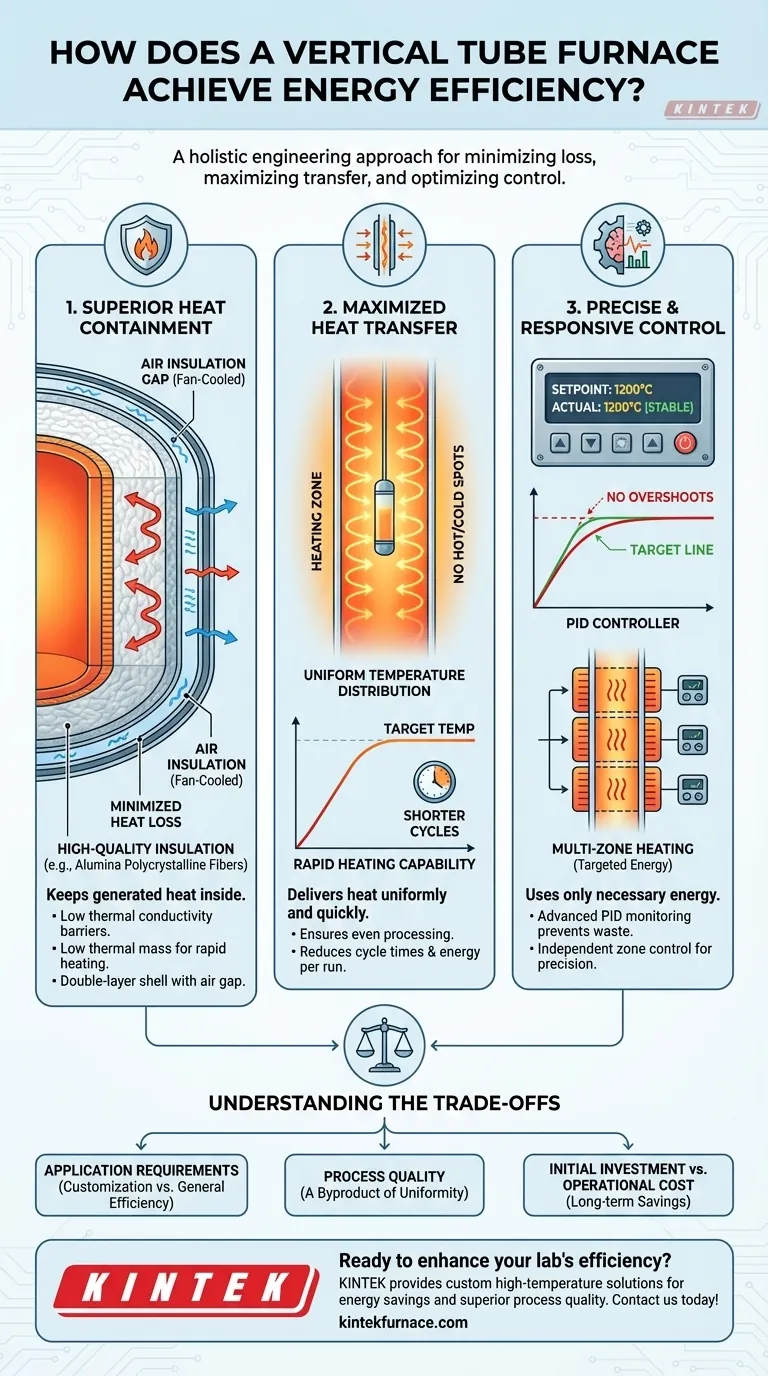

A vertical tube furnace's efficiency is not the result of a single feature, but rather a holistic engineering approach. It systematically combines superior heat containment, effective heat delivery to the target material, and intelligent power management to ensure that nearly every watt of energy serves a purpose.

The Core Pillars of Energy Efficiency

A furnace's energy efficiency can be understood by examining how it manages the flow of heat. An efficient design excels in three distinct areas: preventing heat from escaping, delivering heat effectively to the sample, and using only the necessary amount of energy to do so.

Pillar 1: Superior Heat Containment

The first principle of thermal efficiency is to keep the heat you generate inside the furnace.

- High-Quality Insulation: Modern vertical tube furnaces use materials like alumina polycrystalline fibers or polycrystalline mullite fibers. These materials have very low thermal conductivity, acting as a highly effective barrier to prevent heat from escaping the chamber.

- Low Thermal Mass: This advanced insulation also has a low thermal mass, meaning it heats up quickly and absorbs less energy itself. This allows more energy to be directed toward heating the sample, especially during ramp-up phases.

- Structural Design: Features like double-layer furnace shells with a fan-cooled air gap create an additional layer of insulation. This "air insulation" further reduces the external surface temperature and minimizes ambient heat loss.

Pillar 2: Maximized Heat Transfer

Once heat is contained, it must be transferred to the material being processed as uniformly and quickly as possible.

- Uniform Temperature Distribution: The vertical orientation and heating element design work to create an exceptionally even temperature profile throughout the processing tube. This eliminates "hot" and "cold" spots.

- Why Uniformity Matters: A uniform thermal environment ensures the entire sample reaches the target temperature simultaneously. This prevents the need to extend heating times or increase the setpoint to compensate for cooler areas, both of which waste significant energy.

- Rapid Heating Capability: The combination of low thermal mass insulation and efficient heating elements allows the furnace to reach its target temperature quickly. Shorter cycle times directly translate to lower overall energy consumption per run.

Pillar 3: Precise and Responsive Control

Using too much energy, even for a moment, is a direct source of inefficiency.

- Advanced Temperature Control: Modern furnaces employ sophisticated PID (Proportional-Integral-Derivative) controllers. These systems continuously monitor the temperature and make micro-adjustments to the power output, preventing temperature overshoots that waste energy.

- Multi-Zone Heating: In more advanced models, the furnace tube is divided into multiple independent heating zones. This allows for precise control over the temperature gradient along the tube, ensuring energy is only applied exactly where it is needed for a specific process.

Understanding the Trade-offs

While highly efficient, the design of a vertical tube furnace involves balancing performance with other practical considerations.

Application Requirements vs. General Efficiency

A furnace's efficiency is tied to its intended use. Customizations in tube material, diameter, and length are critical for process success but also influence thermal dynamics. A furnace perfectly optimized for one process may be less efficient for another, highlighting the need for clear application requirements during selection.

Process Quality as a Byproduct of Efficiency

The very features that drive energy efficiency—such as excellent temperature distribution and precise atmosphere control—also directly contribute to higher-quality outcomes. Uniform heating leads to homogeneous material properties, and tight control prevents damage to sensitive substrates, reducing scrap and rework.

Initial Investment vs. Operational Cost

The high-quality materials and advanced control systems that enable top-tier energy efficiency can increase the initial purchase price. However, these upfront costs are often quickly offset by significant savings in long-term energy consumption and operational costs.

Making the Right Choice for Your Goal

To select the right furnace, align its features with your primary objective.

- If your primary focus is process purity and quality: Prioritize models with superior temperature uniformity and precise multi-zone control to ensure homogeneous heat treatment and minimal particle generation.

- If your primary focus is maximizing throughput: Look for features like rapid heating rates and options for automatic wafer or boat transfer to minimize cycle time.

- If your primary focus is minimizing long-term operational costs: Pay closest attention to the quality of the insulation materials and the sophistication of the temperature control system.

Ultimately, choosing an efficient vertical tube furnace is an investment in both reduced energy costs and superior, repeatable process results.

Summary Table:

| Efficiency Pillar | Key Features | Benefits |

|---|---|---|

| Superior Heat Containment | High-quality insulation (e.g., alumina fibers), low thermal mass, double-layer shells | Minimizes heat loss, reduces energy waste |

| Maximized Heat Transfer | Uniform temperature distribution, rapid heating capability | Ensures even processing, shortens cycle times |

| Precise Control | PID controllers, multi-zone heating | Prevents overshoots, optimizes energy use |

Ready to enhance your lab's efficiency with a custom vertical tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering energy savings and superior process quality. Contact us today to discuss how our furnaces can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing