In short, a tube furnace handles heavy feedstocks poorly. The inherent properties of heavy feedstocks, particularly their high propensity for coking, create significant operational challenges. These challenges force operators to make substantial compromises that limit production efficiency and accelerate equipment degradation.

The core issue is that processing heavy feedstocks in a conventional tube furnace is a constant battle against coking. This requires sacrificing performance—through shorter run times and less intense cracking—to manage the rapid buildup of coke and preserve the furnace itself.

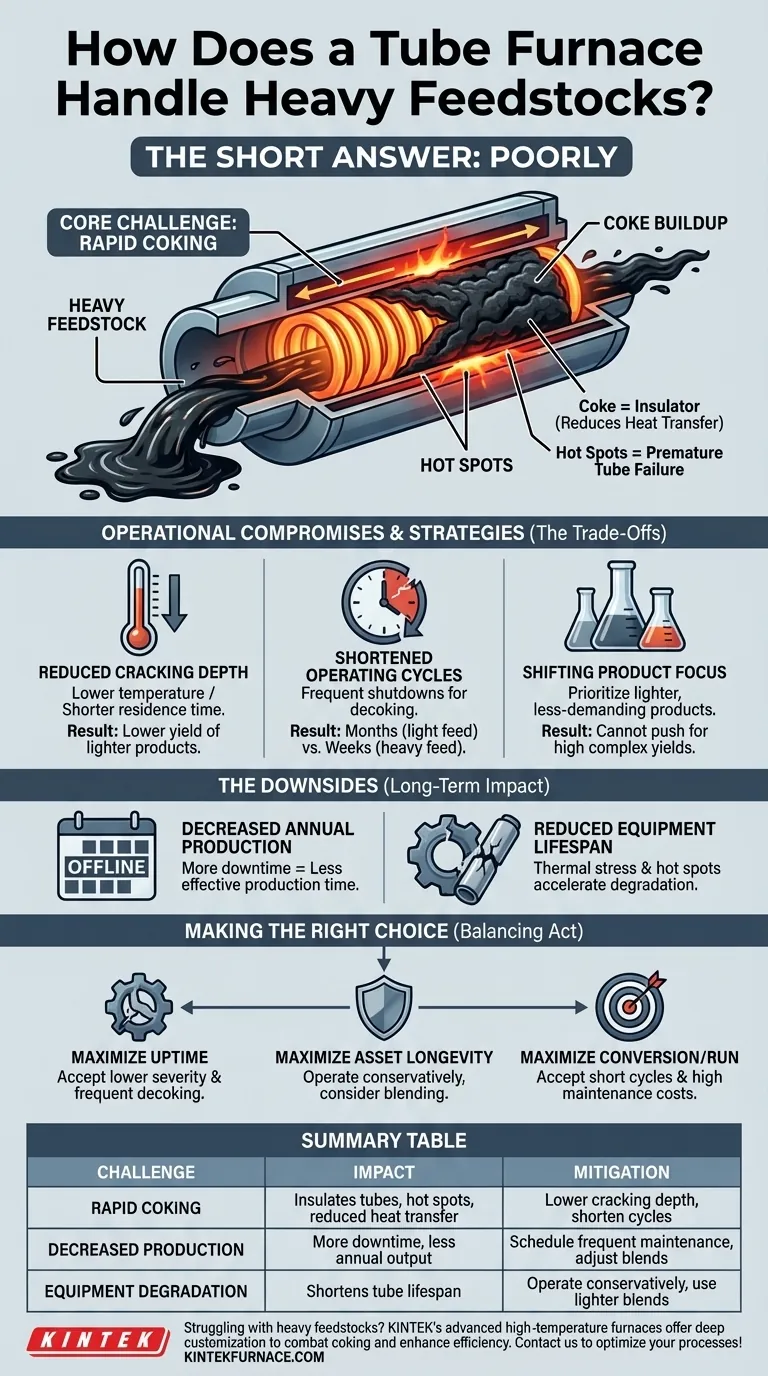

The Core Challenge: Rapid Coking

To understand how a furnace handles heavy feedstocks, you must first understand the primary problem they introduce: coking.

What is Coking?

Coking is the formation of hard, solid carbon deposits (coke) on the inner surfaces of the furnace tubes. These deposits are a byproduct of the thermal cracking reactions, especially at high temperatures.

Why Heavy Feedstocks Accelerate Coking

Heavy feedstocks are rich in complex, high-boiling-point molecules like asphaltenes and heavy aromatics. These components are precursors to coke and are far more prone to polymerization and dehydrogenation reactions that form solid carbon deposits compared to lighter feeds.

The Consequences of Coke Buildup

Coke buildup acts as an insulator, preventing efficient heat transfer from the furnace to the feedstock inside the tube. To maintain the required process temperature, operators must increase the furnace's external temperature.

This creates localized hot spots on the tubes, reducing their mechanical strength and leading to premature failure. Furthermore, the deposits narrow the tube's internal diameter, increasing pressure drop and restricting flow.

Operational Compromises and Strategies

Because of the rapid coking, operators cannot run the furnace under ideal conditions. They must adapt their strategy in several key ways.

Reduced Cracking Depth

Operators are forced to lower the cracking depth or severity. This is typically achieved by reducing the process temperature or shortening the feedstock's residence time in the furnace. While this slows the rate of coking, it also results in lower conversion of the feedstock into valuable lighter products.

Shortened Operating Cycles

Even with reduced severity, coke buildup is inevitable and rapid. This necessitates much shorter operating cycles. A furnace running a light feedstock might operate for months, while one with a heavy feedstock may require shutdown for decoking every few weeks.

Shifting Product Focus

The combination of lower cracking severity and the nature of the feed often means operators must focus on producing lighter, less-demanding products. Pushing for higher yields of complex molecules would accelerate coking to an unmanageable degree.

Understanding the Trade-offs

The strategies used to handle heavy feedstocks come with significant downsides that impact the entire operation.

Decreased Annual Production

Shorter operating cycles directly translate to more frequent shutdowns for decoking. This dramatically reduces the furnace's annual effective production time, as more days are spent offline for maintenance rather than online producing product.

Reduced Equipment Lifespan

The constant cycling between high operating temperatures and the steam-air decoking process induces significant thermal stress on the furnace tubes. This, combined with the risk of hot spots, shortens the lifespan of the furnace tubes and the overall cracking furnace.

Making the Right Choice for Your Goal

Managing heavy feedstocks requires a clear understanding of your operational priorities, as you cannot maximize all objectives simultaneously.

- If your primary focus is maximizing uptime: You must accept a lower cracking severity and plan for frequent, scheduled decoking cycles to prevent severe coke buildup.

- If your primary focus is asset longevity: You should operate at very conservative temperatures and consider blending heavy feedstocks with lighter ones to mitigate the rate of coking.

- If your primary focus is maximizing conversion per run: You must accept the consequence of extremely short operating cycles and the high maintenance costs associated with accelerated equipment degradation.

Ultimately, handling heavy feedstocks is an exercise in carefully balancing competing operational and financial imperatives.

Summary Table:

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Rapid Coking | Insulates tubes, causes hot spots, reduces heat transfer | Lower cracking depth, shorten operating cycles |

| Decreased Production | More downtime for decoking, less annual output | Schedule frequent maintenance, adjust feedstock blends |

| Equipment Degradation | Shortens tube lifespan from thermal stress | Operate at conservative temperatures, use lighter blends |

Struggling with heavy feedstocks in your lab? KINTEK's advanced high-temperature furnaces, including Tube Furnaces and CVD/PECVD Systems, offer deep customization to combat coking and enhance efficiency. Leverage our R&D and in-house manufacturing for tailored solutions—contact us today to optimize your processes and extend equipment life!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a high-vacuum tube furnace necessary for TMD annealing? Protect Your Monolayers from Oxidative Ablation

- Why is high-pressure resistance a critical requirement for SCWG tube reactors? Ensuring Success in Microplastic Energy

- What is the function of a double-zoned tube furnace in CVD of 2DP-F films? Unlock Precise Thin-Film Growth Control

- What is the role of mixing precursor with sulfur powder? Master Sulfidation in Tube Furnaces for Fe7S8@CT-NS

- What are the key factors affecting temperature control in split tube furnaces? Ensure Precision and Uniformity

- How does a manual laboratory jack contribute to process precision in split tube furnaces? Achieve Perfect Alignment

- What are the differences between solid and split tube furnaces? Choose the Right Furnace for Your Lab

- How does a vacuum tube furnace contribute to product sintering? Achieve Pure, High-Density Materials