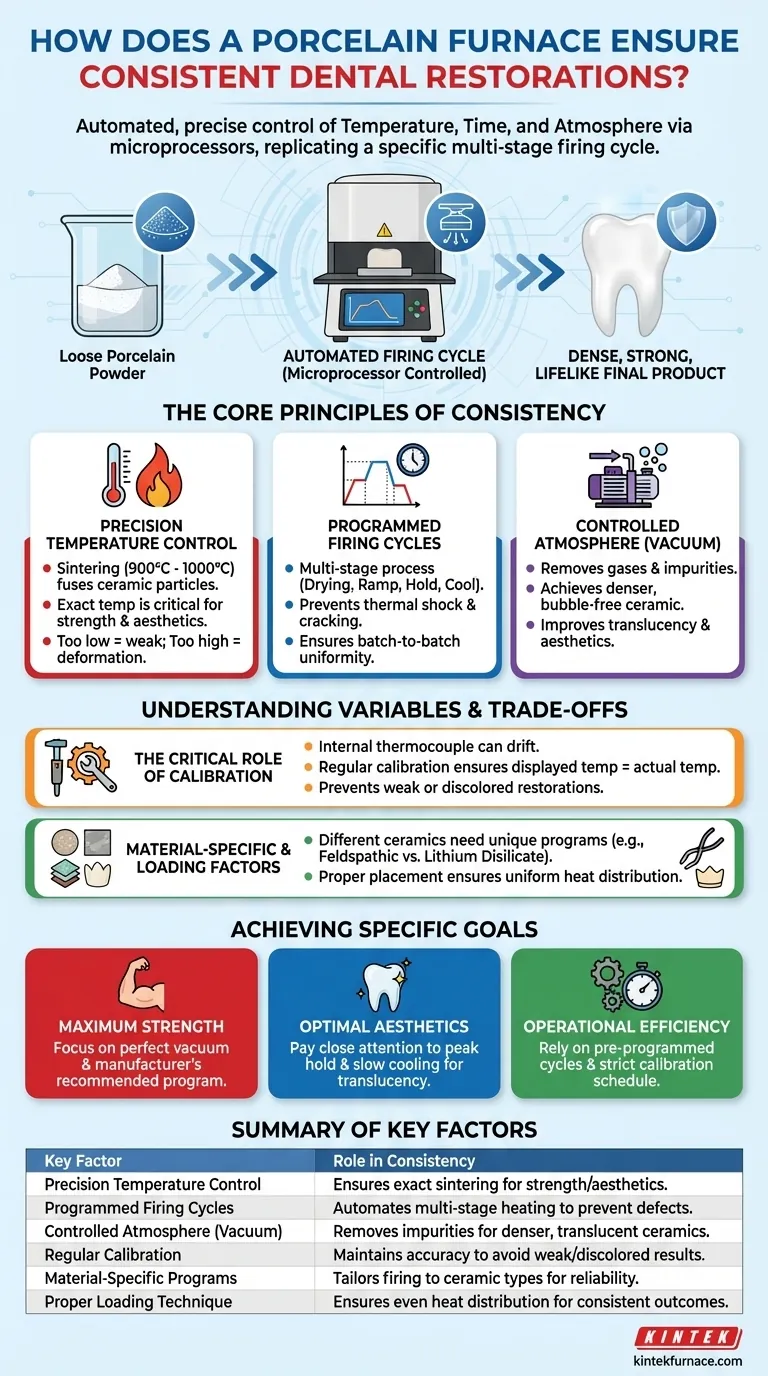

At its core, a porcelain furnace ensures consistent results through the precise and automated control of temperature, time, and atmosphere. This is accomplished using sophisticated microprocessors and pre-set firing programs that manage every stage of the heating and cooling process, removing the guesswork and variability inherent in manual methods.

The consistency of a dental restoration is not born from simple heat, but from the furnace's ability to perfectly replicate a specific, multi-stage firing cycle tailored to the exact ceramic material being used. This transforms loose porcelain powder into a dense, strong, and lifelike final product.

The Core Principles of Firing Consistency

To achieve a predictable outcome, a porcelain furnace must flawlessly manage several interconnected variables. Each one plays a critical role in the final physical and aesthetic properties of the restoration.

Precision Temperature Control

The furnace’s primary function is to heat ceramic materials to their exact sintering temperature, typically between 900°C and 1000°C.

Sintering is the process of fusing ceramic particles together into a solid, dense mass using heat, but without melting the material completely.

Hitting this temperature precisely is non-negotiable. Too low, and the porcelain won't be strong enough; too high, and it can lose its shape, color, and vitality.

Programmed Firing Cycles

Modern furnaces do not simply turn on and off. They execute complex firing programs that dictate the entire thermal journey of the restoration.

These programs control multiple stages, including the initial drying time, the rate of temperature increase, the "hold" time at peak temperature, and the rate of cooling. This control prevents thermal shock, which can cause cracking.

By using pre-set programs specific to a certain brand or type of porcelain, technicians can guarantee that every crown or veneer undergoes the identical process, ensuring batch-to-batch consistency.

Controlled Atmosphere (Vacuum)

During the high-heat phase, most porcelain furnaces create a vacuum inside the firing chamber. This is a critical step for achieving superior aesthetics and strength.

Pulling a vacuum removes atmospheric gases and impurities that can get trapped within the porcelain, which would otherwise create bubbles or cloudiness.

The result is a denser, stronger, and more translucent ceramic that more accurately mimics the appearance of a natural tooth.

Understanding the Trade-offs and Variables

While modern furnaces are highly automated, achieving perfect consistency still requires technical oversight. Inconsistency is almost always a result of a breakdown in one of these key areas.

The Critical Role of Calibration

A furnace is only as accurate as its last calibration. The internal thermocouple, which measures temperature, can drift over time.

Regular calibration is essential to ensure that the temperature displayed on the screen is the actual temperature inside the chamber. A small deviation can lead to weak or discolored restorations.

Material-Specific Requirements

There is no "one-size-fits-all" firing program. Different ceramic systems (e.g., feldspathic, lithium disilicate) have unique temperature and timing requirements.

Using the wrong program for a given material is a primary cause of failed restorations. The furnace’s programmability is only an asset when matched with the correct material data.

The Human Factor in Loading

Even with perfect programming, how a technician places the restoration inside the furnace matters.

Uneven placement can lead to inconsistent heating across the restoration's surface. Proper positioning on the firing tray ensures uniform exposure to heat, which is vital for predictable results.

Making the Right Choice for Your Goal

By understanding these principles, you can leverage your porcelain furnace to achieve specific outcomes with confidence.

- If your primary focus is maximum strength and durability: Ensure the furnace's vacuum function is operating perfectly and always use the ceramic manufacturer's recommended firing program to guarantee complete sintering.

- If your primary focus is optimal aesthetics: Pay close attention to the peak temperature hold and the slow cooling phase, as these stages are critical for developing the desired translucency, value, and shade.

- If your primary focus is operational efficiency: Rely on the furnace’s pre-programmed cycles for common restorations and maintain a strict calibration schedule to minimize costly remakes and wasted time.

Ultimately, a porcelain furnace provides control, and this control empowers you to consistently create restorations that are not only functional but also indistinguishable from natural teeth.

Summary Table:

| Key Factor | Role in Consistency |

|---|---|

| Precision Temperature Control | Ensures exact sintering temperature (900°C-1000°C) for strength and aesthetics |

| Programmed Firing Cycles | Automates multi-stage heating/cooling to prevent defects and ensure uniformity |

| Controlled Atmosphere (Vacuum) | Removes impurities for denser, bubble-free, translucent ceramics |

| Regular Calibration | Maintains temperature accuracy to avoid weak or discolored results |

| Material-Specific Programs | Tailors firing to ceramic types (e.g., feldspathic, lithium disilicate) for reliability |

| Proper Loading Technique | Ensures even heat distribution across the restoration for consistent outcomes |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse range of high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we can precisely meet your unique experimental and production needs, helping you achieve flawless, consistent dental restorations every time. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency