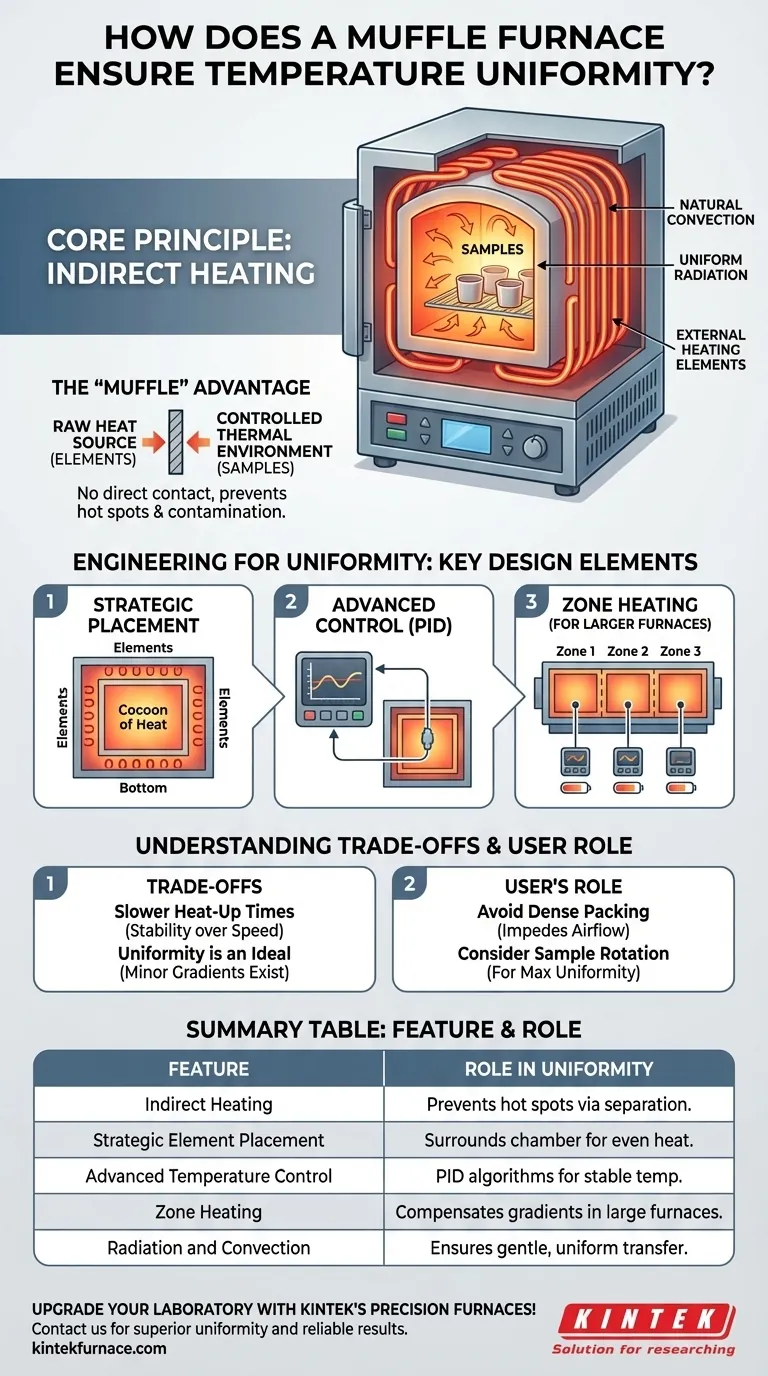

At its core, a muffle furnace ensures temperature uniformity through its fundamental design of indirect heating. The heating elements are positioned outside the primary sample chamber, or "muffle." This physical separation prevents direct radiation hot spots, allowing heat to transfer gently and evenly into the chamber through a combination of radiation and natural convection.

For any high-temperature process, from materials testing to chemical analysis, inconsistent heat is a primary source of unreliable results. A muffle furnace solves this by isolating the sample from the raw heating source, creating a controlled, uniform thermal environment that is the foundation for accuracy and repeatability.

The Core Principle: Indirect Heating

The defining feature of a muffle furnace is the separation between the heating source and the material being processed. This design is the primary reason it can achieve such high levels of temperature uniformity.

How the "Muffle" Works

The term "muffle" refers to the insulated, sealed inner chamber that holds the samples. This chamber is typically made of a high-temperature ceramic material.

Heating elements, such as electrical resistance coils, are wrapped around the outside of this muffle. They do not come into direct contact with the samples or the chamber's atmosphere.

The Role of Radiation and Convection

Heat generated by the external elements radiates inward, warming the walls of the muffle. These heated walls then radiate thermal energy evenly throughout the chamber.

Simultaneously, the air or inert gas inside the chamber heats up, creating natural convection currents. This gentle circulation of the atmosphere further averages out any minor temperature differences, ensuring the entire volume reaches a stable, uniform temperature.

Preventing Hot Spots and Contamination

This indirect approach prevents the intense, localized heat you would get from a direct-fired furnace. Samples are not exposed to the raw, glowing elements, eliminating the risk of one side getting significantly hotter than the other.

As a secondary benefit, this isolation also protects samples from contamination by any particles or gases emitted from the heating elements themselves, which is critical for sensitive processes like elemental analysis.

Engineering for Uniformity: Key Design Elements

Beyond the core principle, modern muffle furnaces employ several specific engineering features to perfect temperature consistency across the entire chamber.

Strategic Placement of Heating Elements

Manufacturers don't just place elements on one side. They are carefully distributed around the muffle—often on the top, bottom, and both sides—to create a "cocoon" of heat that surrounds the chamber from multiple directions.

Advanced Temperature Control

Modern furnaces use sophisticated digital or programmable controllers. A thermocouple inside the chamber constantly measures the temperature and feeds this data back to the controller.

The controller then uses algorithms (like PID control) to precisely modulate the power sent to the heating elements, making tiny adjustments to hold the temperature steady and prevent overshooting or undershooting the setpoint.

Zone Heating for Larger Furnaces

In larger industrial furnaces, achieving uniformity is more challenging. To solve this, advanced models use zone heating. The furnace is divided into multiple heating zones, each with its own set of elements and a dedicated thermocouple.

A central controller monitors each zone independently, delivering more or less power to specific areas as needed to counteract natural temperature gradients and maintain uniformity across a much larger volume.

Understanding the Trade-offs

While muffle furnaces offer superior uniformity, it's important to understand the inherent trade-offs that come with their design.

Slower Heat-Up Times

Because the heat is transferred indirectly, muffle furnaces generally take longer to reach their target temperature compared to direct-fired kilns. The design prioritizes stability and uniformity over raw heating speed.

Perfect Uniformity is an Ideal

Even in the best furnaces, minor temperature gradients will always exist, typically near the door or any ventilation ports. A furnace's specification (e.g., ±5°C) tells you the maximum expected deviation from the setpoint within the usable chamber volume.

Process Can Affect Uniformity

The furnace provides a uniform environment, but the user's process matters. Densely packing the chamber can impede air circulation, creating cool spots. For maximum uniformity within a sample, techniques like periodic sample rotation may still be necessary.

Making the Right Choice for Your Goal

To ensure your process is successful, match the furnace's capabilities to your primary objective.

- If your primary focus is analytical precision (e.g., ashing): Rely on the furnace's indirect heating and programmable controls, but ensure your sample placement is consistent between runs to guarantee reproducibility.

- If your primary focus is materials treatment (e.g., annealing steel): Use pre-programmed heating and cooling ramps to ensure the entire part experiences the thermal cycle uniformly over time, which is critical for achieving desired metallurgical properties.

- If your primary focus is high-volume production: Invest in a furnace with multi-zone heating controls to compensate for temperature gradients in a large, fully loaded chamber and ensure batch-to-batch consistency.

Understanding these principles empowers you to not only select the right equipment but also to use it to its full potential, guaranteeing reliable and repeatable outcomes for your critical work.

Summary Table:

| Feature | Role in Uniformity |

|---|---|

| Indirect Heating | Prevents hot spots by separating heating elements from the chamber |

| Strategic Element Placement | Surrounds chamber for even heat distribution |

| Advanced Temperature Control | Uses PID algorithms to maintain stable temperatures |

| Zone Heating | Compensates for gradients in larger furnaces |

| Radiation and Convection | Ensures gentle, uniform heat transfer |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature uniformity and reliable results. Contact us today to discuss how we can enhance your processes!

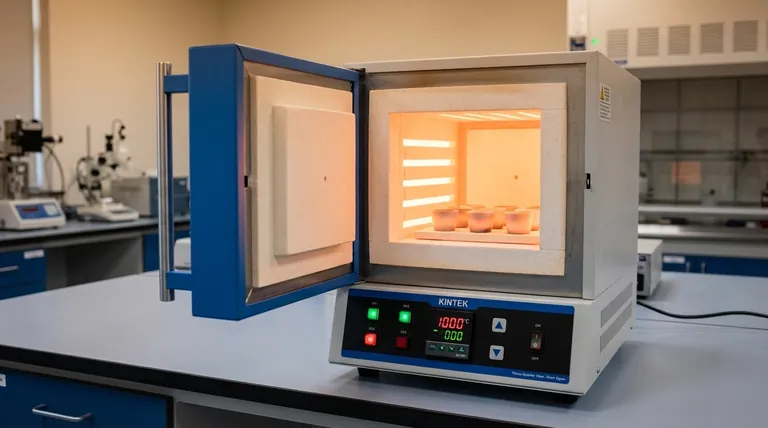

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?