The fundamental difference between a muffle furnace and a conventional furnace lies in one critical principle: isolation. A muffle furnace uses an insulated outer chamber—the "muffle"—to separate the material being heated from the actual heating elements. This indirect heating method prevents contamination and ensures highly uniform temperatures, making it a specialized tool for precision work.

A muffle furnace is not simply a "hotter oven"; it is a purpose-built instrument for applications demanding a pristine, controlled, and evenly heated environment. In contrast, a conventional furnace is designed for general heating where direct exposure to the heat source is acceptable.

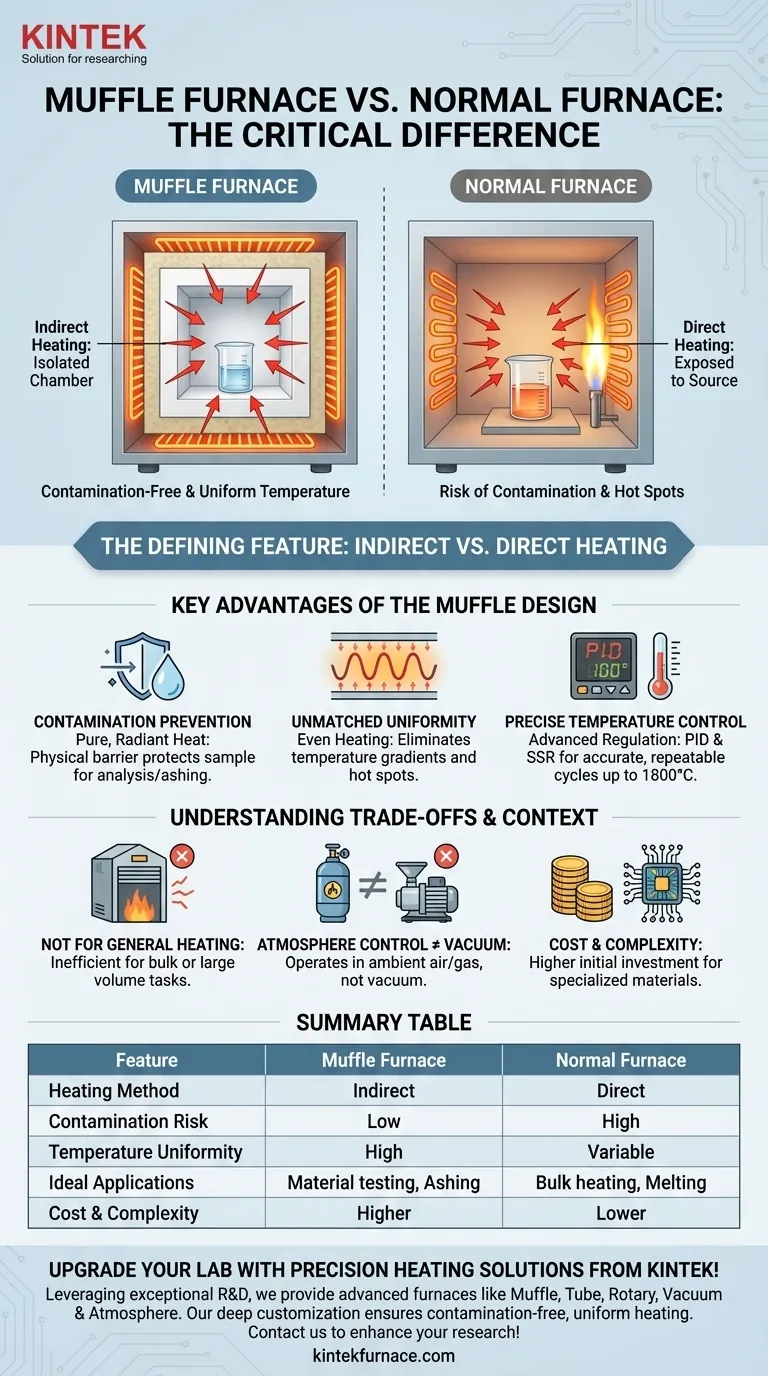

The Defining Feature: Indirect vs. Direct Heating

The core distinction that drives every other difference is how heat is transferred to the sample. This single design choice dictates the furnace's ideal application.

The Muffle Furnace: An Insulated Chamber

A muffle furnace contains the sample within a sealed chamber. The heating elements heat the outside of this chamber, which then radiates thermal energy inward.

This design completely isolates the material from the byproducts of combustion or any particles shed by the heating elements themselves. The result is pure, radiant heat.

The Conventional Furnace: Direct Exposure

A "normal" or conventional furnace, such as a direct-fired industrial unit, often exposes the material directly to the heat source.

This could be an open flame or glowing electric coils within the same chamber as the material. While effective for bulk heating, this method risks contaminating the sample and creating uneven hot spots.

Key Advantages of the Muffle Design

The muffle's indirect heating method delivers three critical advantages for technical and laboratory applications, justifying its use over simpler furnace types.

Contamination Prevention

By creating a physical barrier, the muffle ensures that nothing but heat touches your sample. This is essential for processes like ashing, chemical analysis, or heat-treating sensitive alloys where foreign materials would compromise the results.

The integrity of research and quality control depends on this level of purity.

Unmatched Temperature Uniformity

Because the entire chamber radiates heat inward, the sample is heated evenly from all directions. This eliminates the temperature gradients and hot spots common in direct-heat systems.

Uniform heating is vital for ensuring that a process affects the entire sample consistently, from its surface to its core.

Precise Temperature Control

Muffle furnaces are built for accuracy. They integrate sophisticated PID (Proportional-Integral-Derivative) controllers and SSR-based heaters to precisely regulate and maintain target temperatures, often up to 1800°C.

Features like auto-tuning and high-grade insulation maximize thermal efficiency, allowing for repeatable and reliable heating cycles crucial for scientific testing.

Understanding the Trade-offs and Context

While powerful, a muffle furnace is a specialized tool. Understanding its limitations is key to using it correctly.

Not for General Heating

A muffle furnace is inefficient for general-purpose heating, like warming a large space or pre-heating bulk raw materials. Its design prioritizes precision over raw power and volume, making it overkill for tasks where contamination is not a concern.

Atmosphere Control vs. Atmosphere Removal

A muffle furnace isolates the sample from the heat source, but it typically operates in ambient air or a controlled gas atmosphere. It does not create a vacuum.

For processes that are sensitive to any atmospheric gases, like oxidation, a vacuum furnace is required. A vacuum furnace removes all air and gas, providing an even higher level of environmental purity.

Cost and Complexity

The specialized materials, high-grade insulation, and advanced electronic controls make muffle furnaces significantly more complex and expensive than simple direct-fired or convection ovens. Their cost is justified only when process purity and temperature precision are non-negotiable.

Making the Right Choice for Your Application

Selecting the right thermal processing equipment depends entirely on your goal. The key is to match the tool to the specific demands of your material and process.

- If your primary focus is material testing, ashing, or heat-treating sensitive components: A muffle furnace is the correct choice for its purity and absolute temperature uniformity.

- If your primary focus is bulk heating, melting, or forging where direct contact is acceptable: A conventional direct-fired furnace is more efficient and cost-effective.

- If your primary focus is preventing any atmospheric reaction, such as oxidation: You must use a vacuum furnace, which offers a higher level of environmental control.

Understanding the fundamental difference in heating methods empowers you to select the precise tool your process demands.

Summary Table:

| Feature | Muffle Furnace | Normal Furnace |

|---|---|---|

| Heating Method | Indirect (isolated chamber) | Direct (exposed to heat source) |

| Contamination Risk | Low (prevents contamination) | High (risk of contamination) |

| Temperature Uniformity | High (even heating) | Variable (hot spots possible) |

| Ideal Applications | Material testing, ashing, sensitive heat treatment | Bulk heating, melting, forging |

| Cost and Complexity | Higher (specialized design) | Lower (general-purpose) |

Upgrade your lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for contamination-free, uniform heating. Contact us today to discuss how our tailored furnace solutions can enhance your research and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis