To select the right IGBT induction furnace, you must match two primary factors to the metal you intend to melt: the furnace's power and capacity (e.g., 15kW for 3kg of steel) and the crucible's material composition. The furnace provides the energy, but the crucible is the critical component that must withstand the target temperature and avoid chemical reactions with the molten metal.

The most common mistake is focusing only on the furnace's power and capacity. The correct approach is to view the furnace and the crucible as an integrated system, where the crucible material is chosen specifically for the metal's melting point and chemical reactivity.

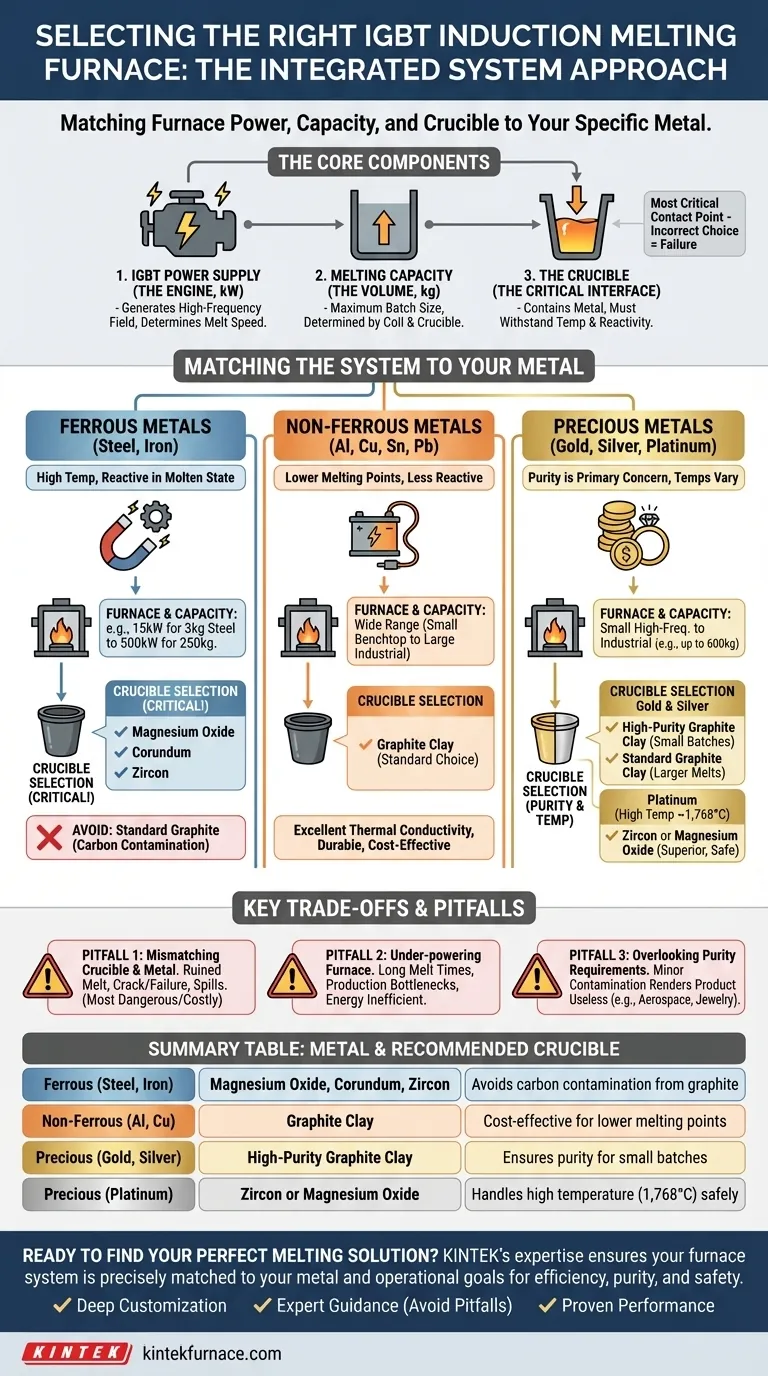

The Core Components of Your Melting System

An induction furnace is more than just a power supply. Understanding its three key components is essential for making an informed decision.

The IGBT Power Supply (The Engine)

The power supply, rated in kilowatts (kW), is the engine of your furnace. It generates the high-frequency magnetic field that induces heat directly within the metal.

A higher kW rating translates to faster melting times for a given amount of metal. This is a critical factor for operational efficiency and throughput.

Melting Capacity (The Volume)

Capacity, measured in kilograms (kg), defines the maximum amount of a specific metal the furnace can melt in a single batch. This is determined by the physical size of the induction coil and the crucible it can hold.

Furnace models are often specified by both power and capacity, such as a 15kW furnace designed for a 3kg crucible.

The Crucible (The Critical Interface)

The crucible is the vessel that contains the metal during melting. It is the most critical point of contact and must be chosen with extreme care.

An incorrect crucible can lead to melt contamination, poor performance, or catastrophic failure. The material must be able to handle the extreme temperatures and not react chemically with the molten metal.

Matching the Furnace System to Your Metal

The specific metal you are melting dictates the requirements for both the crucible and the furnace's power-to-capacity ratio.

For Ferrous Metals (Steel, Iron)

These high-temperature metals are reactive in their molten state.

- Furnace & Capacity: Models typically range from a 15kW unit for 3kg of steel up to a 500kW unit capable of melting 250kg.

- Crucible Selection: You must use a ceramic crucible made from magnesium oxide, corundum, or zircon. Using a standard graphite crucible will introduce carbon into the steel, contaminating the alloy.

For Non-Ferrous Metals (Aluminum, Copper, Tin, Lead)

These common industrial metals have lower melting points and are generally less reactive than steel.

- Furnace & Capacity: The power and capacity ranges are similar to those for steel, from small benchtop units to large industrial furnaces.

- Crucible Selection: Graphite clay crucibles are the standard choice. They offer excellent thermal conductivity and durability for these applications and are highly cost-effective.

For Precious Metals (Gold, Silver, Platinum)

Purity is often the primary concern when melting precious metals, and temperatures can vary significantly.

- Furnace & Capacity: Small, high-frequency furnaces are common, but capacities can range from a few kilograms up to 600kg for industrial operations.

- Crucible Selection for Gold & Silver: High-purity graphite clay crucibles are ideal for smaller batches where maintaining purity is paramount. Standard graphite clay is sufficient for larger melts.

- Crucible Selection for Platinum: Platinum has a very high melting point (1,768°C / 3,215°F), similar to steel. To prevent contamination and ensure safety at this temperature, a zircon or magnesium oxide crucible is the technically superior and safer choice.

Understanding the Key Trade-offs

Choosing a furnace involves balancing cost, performance, and safety. Avoiding common pitfalls is essential.

Pitfall 1: Mismatching Crucible and Metal

This is the most dangerous and costly mistake. Using a graphite crucible for steel will ruin the melt. Using a crucible not rated for the target temperature can cause it to crack or fail, spilling molten metal.

Pitfall 2: Under-powering Your Furnace

Selecting a furnace with a low kW rating for a large capacity will result in extremely long melt times. This not only creates a production bottleneck but is also energy-inefficient, as the system will suffer from greater heat loss over the extended period.

Pitfall 3: Overlooking Purity Requirements

For applications like investment casting of jewelry or aerospace components, even minor contamination from the wrong crucible can render the final product useless. Always choose the crucible based on the final purity requirements of your metal.

Making the Right Choice for Your Operation

Use your primary goal to guide your final selection.

- If your primary focus is high-temperature ferrous metals like steel or iron: Prioritize a system with a magnesium oxide, corundum, or zircon crucible and ensure the power supply is sufficient for your desired melt time.

- If your primary focus is general-purpose non-ferrous metals like aluminum or copper: A furnace system using a standard graphite clay crucible is a reliable and cost-effective choice.

- If your primary focus is high-purity precious metals: For small batches of gold and silver, invest in high-purity graphite crucibles. For platinum, specify a ceramic crucible (zircon or magnesium oxide) to handle the heat and prevent contamination.

Choosing the right furnace is about aligning power, capacity, and material science to guarantee efficient, clean, and safe melting.

Summary Table:

| Metal Type | Recommended Crucible Material | Key Consideration |

|---|---|---|

| Ferrous (Steel, Iron) | Magnesium Oxide, Corundum, Zircon | Avoids carbon contamination from graphite |

| Non-Ferrous (Aluminum, Copper) | Graphite Clay | Cost-effective for lower melting points |

| Precious (Gold, Silver) | High-Purity Graphite Clay | Ensures purity for small batches |

| Precious (Platinum) | Zircon or Magnesium Oxide | Handles high temperature (1,768°C) safely |

Ready to find your perfect melting solution?

KINTEK's expertise ensures your furnace system is precisely matched to your metal and operational goals. We go beyond just selling a furnace; we partner with you to design an integrated system that guarantees efficiency, purity, and safety.

Why choose KINTEK?

- Deep Customization: Leveraging our exceptional R&D and in-house manufacturing, we tailor our advanced high-temperature furnace solutions—including IGBT Induction Melting Furnaces—to your unique requirements.

- Expert Guidance: Our specialists help you avoid common pitfalls, ensuring the correct power-to-capacity ratio and crucible material for your specific metal.

- Proven Performance: From small precious metal batches to large industrial melts, our systems deliver reliable, clean, and efficient results.

Contact us today to discuss your project and receive a personalized recommendation. Let's build the ideal melting system for your lab or foundry.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications