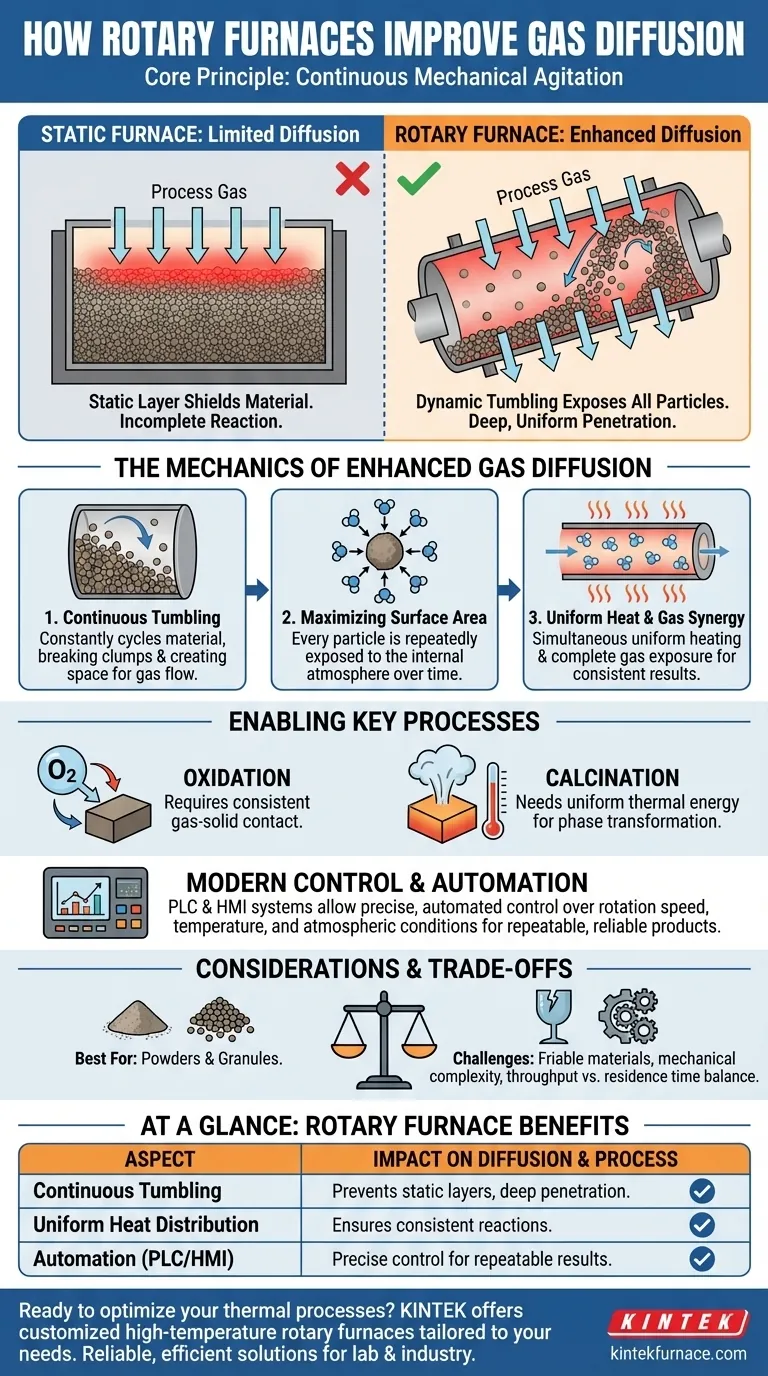

At their core, rotary furnaces improve gas diffusion through continuous mechanical agitation. The slow, constant rotation of the furnace tube tumbles the material being processed, ensuring that every particle is repeatedly and thoroughly exposed to the internal atmosphere. This dynamic action prevents the formation of a static top layer that would otherwise shield the bulk of the material, allowing process gases to penetrate deeply and uniformly.

The primary advantage of a rotary furnace is not just one feature, but the synergy between its core actions: rotation provides uniform heat and complete gas exposure simultaneously. This turns a potentially inefficient static process into a highly consistent, continuous operation.

The Mechanics of Enhanced Gas Diffusion

In many thermal processes, ensuring that a gas can react with a solid material is the central challenge. A rotary furnace is designed specifically to solve this problem.

Overcoming the Static Layer Problem

In a stationary furnace, process gases can only interact with the top layer of the material bed. The particles below are shielded, leading to an incomplete or highly inefficient reaction.

This means the process is limited by the slow rate at which gas can diffuse through a packed, static powder or granular bed.

The Role of Continuous Tumbling

A rotary furnace consists of a long, inclined barrel that rotates slowly. This motion continuously lifts the material and causes it to cascade or tumble down.

This simple mechanical action is the key. It constantly cycles material from the bottom of the bed to the surface, breaking up any clumps and creating space for gas to flow.

Maximizing Surface Area Exposure

By tumbling the material, the furnace ensures the entire surface area of every particle is exposed to the process gas over time. This transforms the reaction from a surface-level phenomenon into a true bulk process.

This enhanced exposure not only improves the completeness of the reaction but can also increase the reaction speed and reduce overall gas consumption.

Beyond Diffusion: The Principle of Uniformity

The benefits of the rotary design extend beyond gas diffusion, creating a highly controlled and efficient processing environment.

Consistent Heat Distribution

The same rotation that exposes material to gas also ensures uniform heat exposure. As particles tumble, they are evenly heated by the furnace walls, which receive energy from external heating elements.

This indirect heating method prevents hot spots and thermal gradients, ensuring every particle experiences the same temperature profile, which is critical for process repeatability.

Enabling Key Chemical Processes

This level of control is essential for processes like oxidation and calcination. Oxidation, which involves a gain of oxygen, fundamentally requires consistent gas-solid contact to proceed effectively.

Similarly, calcination uses thermal energy to drive phase transformations, which occur most predictably when heating is perfectly uniform.

Automation and Process Control

Modern rotary furnaces leverage Programmable Logic Controllers (PLCs) and Human-Machine Interface (HMI) systems. These tools allow for precise, automated control over rotation speed, temperature, and atmospheric conditions.

This automation ensures that the uniform conditions are maintained consistently, leading to higher operational efficiency and a more repeatable, reliable final product.

Understanding the Trade-offs

While highly effective, rotary furnaces are not a universal solution. Their design introduces specific considerations that must be weighed.

Material Suitability

The tumbling action is ideal for powders, granules, and small solids. However, it can be too aggressive for friable materials that are easily broken or abraded. Extremely fine powders may also become airborne and require special handling.

Mechanical Complexity

Compared to a static box furnace, a rotary furnace is a more complex machine. The rotating barrel requires specialized seals, drive motors, and support bearings that add to the maintenance burden.

Throughput vs. Residence Time

There is an inherent trade-off between the processing speed (throughput) and the time the material spends in the furnace (residence time). A faster rotation or steeper incline will increase throughput but reduce the time available for reactions to complete, requiring careful calibration.

Applying This to Your Process

Choosing the right furnace technology depends on balancing process requirements with operational complexity.

- If your primary focus is achieving a complete gas-solid reaction (like oxidation): The rotary furnace is superior because its continuous tumbling guarantees uniform gas exposure throughout the material.

- If your primary focus is high-throughput processing of powders or granules: A continuous rotary furnace is ideal, as it combines uniform heating and reaction with an efficient, automated workflow.

- If you are processing large, single solid objects or materials prone to breakage: A static or batch furnace may be more appropriate, as the tumbling action of a rotary furnace could cause damage.

Ultimately, the rotary furnace excels by transforming the material bed from a static barrier into a dynamic, reactive volume.

Summary Table:

| Aspect | Impact on Gas Diffusion |

|---|---|

| Continuous Tumbling | Prevents static layers, exposes all particles to gas for deep penetration |

| Uniform Heat Distribution | Ensures even temperature, supporting consistent reactions like oxidation |

| Automation (PLC/HMI) | Allows precise control of rotation and atmosphere for repeatable results |

| Material Suitability | Best for powders and granules; may not suit friable or fine materials |

Ready to optimize your thermal processes with advanced rotary furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnaces tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're handling powders, granules, or need enhanced gas diffusion for oxidation and calcination, KINTEK delivers reliable, efficient solutions. Contact us today to discuss how we can improve your lab's performance and achieve superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries