In the pharmaceutical industry, muffle furnaces are foundational tools for sample processing and quality control. They provide a precisely controlled, high-temperature environment essential for preparing samples for further analysis, testing raw material purity, and performing thermal treatments on compounds and materials. Key applications include ashing, loss-on-ignition testing, calcination, and thermal degradation studies.

Pharmaceutical analysis requires absolute precision and repeatability. A muffle furnace achieves this by using indirect heat in an insulated chamber, which eliminates temperature fluctuations and protects samples from contamination, ensuring any changes are solely due to the intended thermal process.

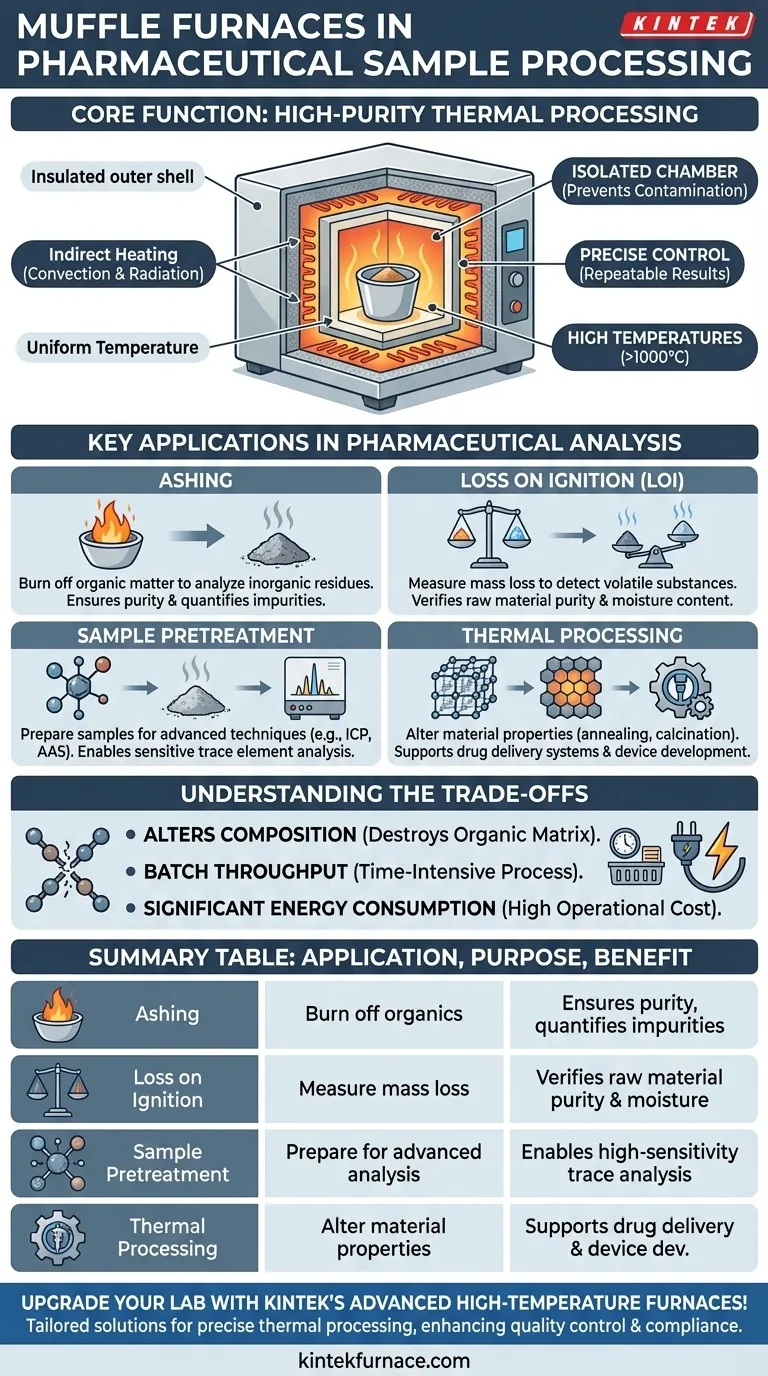

The Core Function: High-Purity Thermal Processing

A muffle furnace is not just a high-temperature oven. Its design is central to its role in sensitive analytical work. The defining feature is the "muffle," an inner chamber that isolates the sample from the heating elements and any combustion byproducts.

What Makes a "Muffle" Different?

The muffle chamber heats samples through convection and radiation rather than direct exposure to a flame or heating element. This indirect heating method is critical for preventing contamination.

By shielding the sample, the furnace ensures that the only variable being tested is the effect of heat, which is paramount for the stringent quality standards in pharmaceuticals.

Ensuring Uniformity and Precision

The insulated chamber minimizes heat loss and creates an extremely uniform thermal environment. This consistency is vital for repeatable experiments and reliable quality control.

Whether performing drug testing or pretreating medical samples, this precision guarantees that results from different batches can be compared accurately.

Beyond Standard Ovens

Muffle furnaces can achieve temperatures far higher than conventional ovens, often exceeding 1000°C. This capability is necessary for processes like ashing and calcination, where complete combustion or thermal decomposition is required.

Key Applications in Pharmaceutical Analysis

Muffle furnaces support several critical quality control and sample preparation procedures that are mandated by regulatory standards.

Ashing for Inorganic Content Analysis

Ashing is a process where a sample is heated at high temperatures to burn off all organic matter, leaving behind only the inorganic, non-combustible residue (ash).

This is a fundamental quality control test to quantify the inorganic impurity profile of a drug substance or raw material. The resulting ash can then be analyzed further using techniques like spectroscopy.

Loss on Ignition (LOI) Testing

Loss on Ignition is a related test that measures the change in mass of a sample after being heated in a muffle furnace. It is used to determine the content of volatile or organic substances.

In pharmaceuticals, this helps verify the purity of raw materials and ensure they are free from excessive moisture or organic contaminants that could compromise the final product.

Sample Pretreatment for Advanced Analysis

Many modern analytical instruments require samples to be in a simple, inorganic form to function correctly. A muffle furnace is the essential tool for this pretreatment.

By reducing a complex medical or pharmaceutical sample to a simple ash, analysts prepare it for highly sensitive techniques that detect trace elements or contaminants.

Thermal Processing and Materials Science

Beyond analysis, muffle furnaces are used to alter the physical properties of materials. Processes like annealing (to increase ductility) or quenching (to harden) can be applied to materials used in medical devices or advanced drug delivery systems.

They are also used for calcination, a process that heats solids to high temperatures to induce a chemical change, such as removing water or creating a new crystal structure in a pharmaceutical compound.

Understanding the Trade-offs

While indispensable, the muffle furnace has specific characteristics that make it suitable for some tasks but not others.

Sample Composition is Altered

The primary function of a muffle furnace in ashing is to destroy the organic matrix. Therefore, it is entirely unsuitable for any analysis focused on identifying or quantifying volatile or organic compounds within the original sample.

Throughput is Limited to Batches

Muffle furnaces are batch-processing instruments. Loading, heating, cooling, and unloading a set of samples takes a significant amount of time, which can be a bottleneck in high-throughput environments.

Significant Energy Consumption

Reaching and maintaining temperatures of 500°C to over 1000°C requires a substantial amount of energy. This is a practical operational cost for any laboratory to consider.

Applying This to Your Analytical Goal

The specific use of a muffle furnace depends entirely on your objective, whether it's routine testing, sample preparation, or research.

- If your primary focus is routine quality control: Use the furnace for standardized ashing and loss-on-ignition tests to verify the purity of raw materials and quantify inorganic content in final products.

- If your primary focus is preparing samples for trace element analysis: The muffle furnace is your essential first step to remove the organic matrix before using instrumental techniques like atomic absorption spectroscopy (AAS) or inductively coupled plasma (ICP).

- If your primary focus is materials research: Leverage the furnace's precise thermal control for calcination, annealing, and stability studies to develop new materials for drug delivery or medical devices.

Ultimately, mastering the muffle furnace is fundamental to guaranteeing the safety, quality, and efficacy of pharmaceutical products.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ashing | Burn off organic matter to analyze inorganic residues | Ensures purity and quantifies impurities in drugs |

| Loss on Ignition (LOI) Testing | Measure mass loss to detect volatile substances | Verifies raw material purity and moisture content |

| Sample Pretreatment | Prepare samples for advanced analytical techniques | Enables trace element analysis with high sensitivity |

| Thermal Processing | Alter material properties via annealing or calcination | Supports development of drug delivery systems and devices |

Upgrade your pharmaceutical lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise thermal processing for your unique analytical needs, enhancing quality control, efficiency, and compliance. Contact us today to discuss how we can support your sample processing and drive innovation in your projects!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production