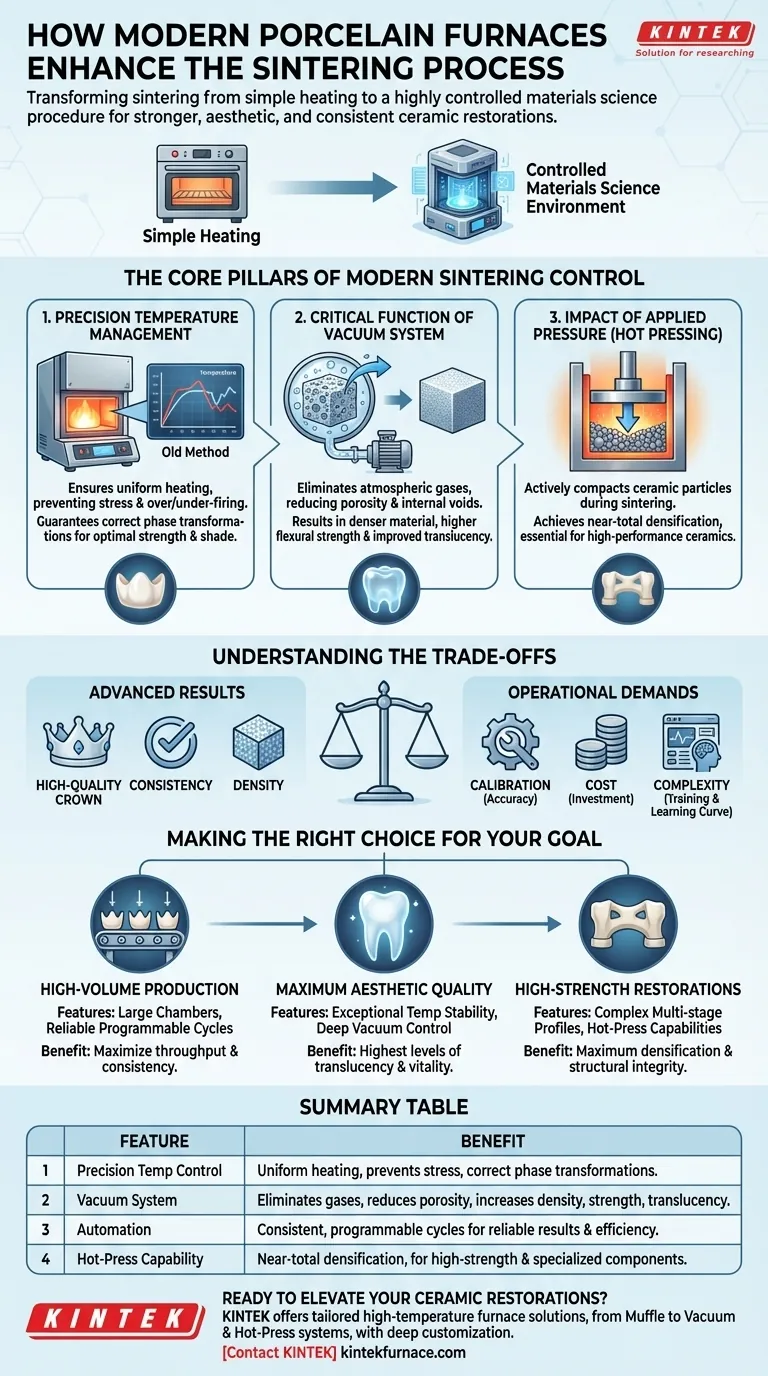

In essence, modern porcelain furnaces enhance sintering by transforming it from a simple heating process into a highly controlled materials science procedure. They achieve this through precise management of temperature, the strategic use of a vacuum to control the atmosphere, and advanced automation, which together produce stronger, more aesthetic, and more consistent ceramic restorations.

The fundamental shift is from merely baking porcelain to creating an engineered environment. This environment actively removes structural imperfections and ensures complete material densification, which is the true goal of the sintering process.

The Core Pillars of Modern Sintering Control

A modern furnace's value lies in its ability to precisely manipulate the physical and atmospheric conditions inside its chamber. This control directly impacts the final properties of the ceramic.

The Role of Precision Temperature Management

The most critical variable in sintering is temperature. Modern furnaces provide exceptional control over the heating and cooling cycles.

This high-precision temperature control, with minimal fluctuation, ensures the entire restoration is heated evenly. This prevents one part from being over-fired while another is under-fired, which is a common cause of internal stress and weakness.

By adhering strictly to the ceramic manufacturer's recommended temperature profile, the furnace guarantees that the material undergoes the correct phase transformations to achieve its target strength and shade.

The Critical Function of the Vacuum System

Many material failures are caused by porosity, which are microscopic voids or air bubbles trapped within the ceramic. A vacuum system directly addresses this problem.

By removing the air from the chamber before and during the high-temperature phases, the vacuum eliminates atmospheric gases. This prevents them from being trapped inside the porcelain as it fuses together.

The result is a significantly denser final material. Higher density directly correlates to greater flexural strength, higher fracture resistance, and improved translucency, as there are fewer internal voids to scatter light.

The Impact of Applied Pressure (Hot Pressing)

Some advanced furnaces, known as hot-press furnaces, add another layer of control by applying mechanical pressure during the sintering cycle.

This combination of vacuum, heat, and external pressure actively compacts the ceramic particles. It is a powerful method for achieving near-total densification, which is essential for high-performance ceramics or specialized industrial components.

Understanding the Trade-offs

While advanced features offer superior results, they also introduce complexity and new operational requirements. Understanding these trade-offs is crucial for any professional.

Accuracy Demands Calibration

A high-precision furnace is only as good as its last calibration. These sensitive instruments require regular, meticulous calibration of their temperature and pressure sensors to deliver on their promise of accuracy. An uncalibrated advanced furnace can produce worse results than a simpler, properly maintained one.

The Cost of Control

Furnaces with advanced vacuum systems, programmable controls, and hot-press capabilities represent a significant capital investment. The benefits of higher quality and consistency must be weighed against the initial cost and ongoing maintenance expenses.

Operational Complexity

Sophisticated multi-stage programs with vacuum and pressure controls have a steeper learning curve. Proper training is essential to avoid user error, which can easily ruin a batch of restorations and negate the benefits of the technology.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the specific objectives of your lab or practice. The technology must match the work you are producing.

- If your primary focus is high-volume production: Prioritize furnaces with larger chambers and reliable, easily programmable cycles to maximize throughput and consistency across many units.

- If your primary focus is maximum aesthetic quality: Invest in a furnace with exceptional temperature stability and deep vacuum control to achieve the highest levels of translucency and vitality in your ceramics.

- If your primary focus is high-strength restorations: Consider a furnace capable of executing complex, multi-stage sintering profiles with absolute precision, and potentially hot-press capabilities for maximum densification.

Ultimately, mastering modern furnace technology empowers you to control the final properties of your restorations at a material level.

Summary Table:

| Feature | Benefit |

|---|---|

| Precision Temperature Control | Ensures uniform heating, prevents stress, and guarantees correct phase transformations for optimal strength and shade. |

| Vacuum System | Eliminates atmospheric gases, reduces porosity, and increases material density for higher flexural strength and translucency. |

| Automation | Provides consistent, programmable cycles for reliable results and improved efficiency in high-volume or aesthetic-focused labs. |

| Hot-Press Capability | Combines heat, vacuum, and pressure for near-total densification, ideal for high-strength restorations and specialized components. |

Ready to elevate your ceramic restorations with advanced sintering technology? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're focused on high-volume production, maximum aesthetic quality, or high-strength restorations, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your lab's performance and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations