At their core, graphite crucible furnaces improve processing times because graphite itself is an exceptional conductor of heat. This property allows for a rapid transfer of energy from the heating elements to the material being processed, significantly reducing the time it takes to reach target temperatures compared to furnaces using materials with lower thermal conductivity.

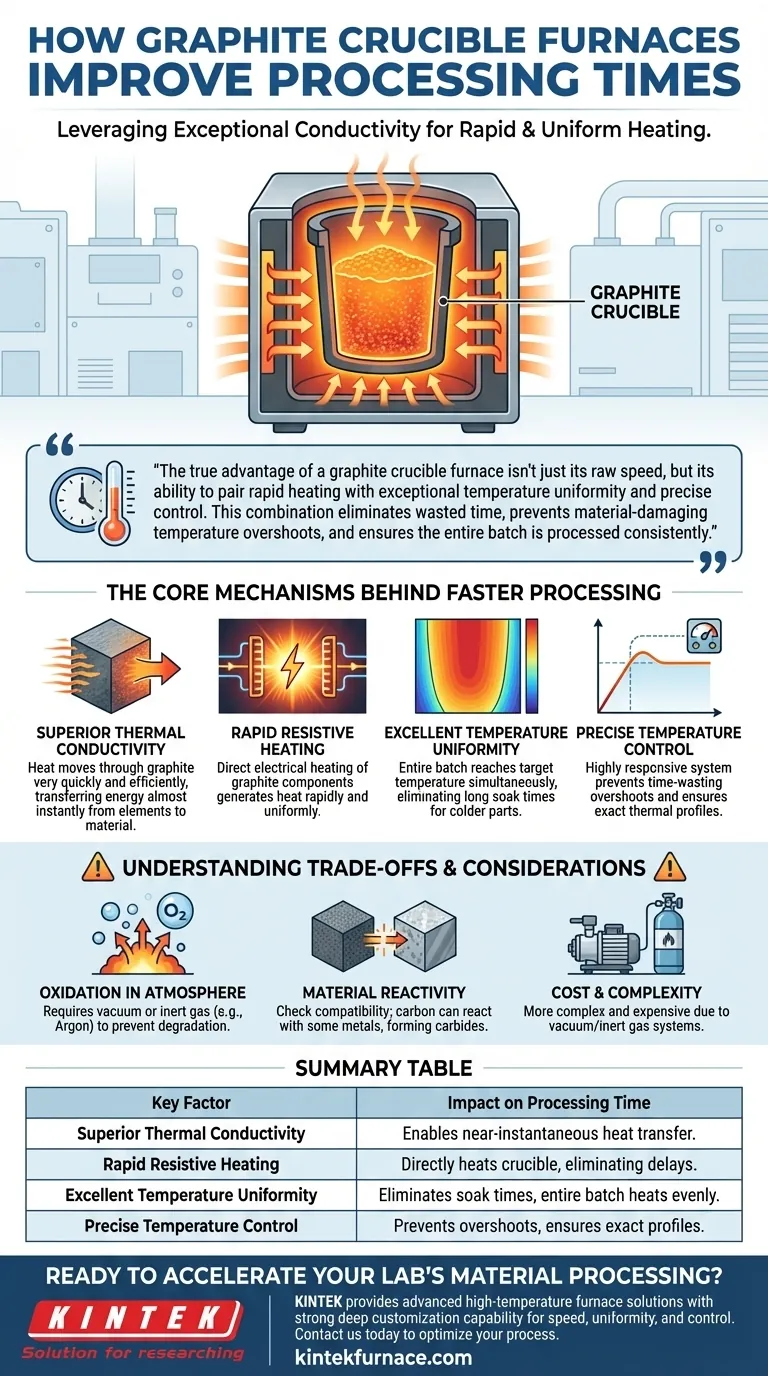

The true advantage of a graphite crucible furnace isn't just its raw speed, but its ability to pair rapid heating with exceptional temperature uniformity and precise control. This combination eliminates wasted time, prevents material-damaging temperature overshoots, and ensures the entire batch is processed consistently.

The Core Mechanisms Behind Faster Processing

To understand why these furnaces are so efficient, we must look at the specific properties of graphite and how they are leveraged in the furnace's design. The time savings come from a combination of factors working in concert.

Superior Thermal Conductivity

Graphite has extremely high thermal conductivity. This means heat moves through it very quickly and efficiently.

When the furnace's heating elements (often made of graphite as well) get hot, that energy is transferred almost instantly through the graphite crucible to the material inside.

Rapid Resistive Heating

Many graphite furnaces use the graphite components themselves as resistive heating elements. An electrical current is passed directly through them, generating heat rapidly and uniformly.

This direct heating method is inherently faster and more efficient than indirect methods where heat must first radiate through a chamber before reaching the crucible.

Excellent Temperature Uniformity

Because heat moves so well through graphite, the entire crucible and its contents tend to maintain a very even temperature. This eliminates "hot spots" and "cold spots."

This uniformity is critical for reducing processing time. You don't need to add long "soak" periods to the cycle just to wait for the colder parts of your material to catch up to the hotter parts. The entire batch reaches the target temperature almost simultaneously.

Precise Temperature Control

The responsiveness of graphite allows for extremely precise temperature management. The system can quickly adjust power to prevent overshooting the target temperature.

Overshooting is a significant source of wasted time, as it requires a cooling period before the process can resume. The precise control of a graphite furnace ensures the thermal profile is followed exactly, minimizing cycle time.

Understanding the Trade-offs and Considerations

While highly efficient, graphite crucible furnaces are not a universal solution. Their unique properties come with specific operational requirements and limitations that must be understood.

Oxidation in Atmosphere

Graphite reacts with oxygen and will rapidly degrade (oxidize) at high temperatures.

For this reason, these furnaces must be operated in a vacuum or be filled with an inert gas like argon. This adds significant complexity and cost to the system compared to a furnace that can operate in open air.

Material Reactivity

At the high temperatures these furnaces achieve, carbon can be reactive. Certain metals or materials may react with the graphite crucible, forming unwanted carbides.

The choice of material to be processed must be compatible with a carbon environment, or a protective inner liner (e.g., a ceramic crucible within the graphite one) may be necessary.

Cost and Complexity

The need for vacuum pumps, inert gas handling systems, and sophisticated power supplies makes graphite furnaces more complex and generally more expensive to purchase and operate than simpler furnace types.

Making the Right Choice for Your Application

Selecting a furnace technology requires matching its capabilities to your specific process goals. The speed of a graphite furnace is only an advantage if its other characteristics align with your needs.

- If your primary focus is maximum processing speed and precision for sensitive materials: The combination of rapid heating, uniformity, and control in a graphite furnace is unparalleled for applications like sintering, graphitization, and advanced material synthesis.

- If your primary focus is general-purpose melting or heat treatment in an air atmosphere: The complexity and inert-environment requirement of a graphite system are likely unnecessary, and a different furnace type would be more cost-effective.

Understanding these core principles allows you to select the right tool not just for speed, but for the specific quality and consistency demands of your material process.

Summary Table:

| Key Factor | Impact on Processing Time |

|---|---|

| Superior Thermal Conductivity | Enables near-instantaneous heat transfer from elements to the material. |

| Rapid Resistive Heating | Directly heats the crucible, eliminating delays from indirect methods. |

| Excellent Temperature Uniformity | Eliminates soak times by ensuring the entire batch heats evenly and simultaneously. |

| Precise Temperature Control | Prevents time-wasting temperature overshoots and ensures exact thermal profiles. |

Ready to accelerate your lab's material processing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is built with the same principles of speed, uniformity, and control.

If your research demands maximum processing speed and precision for sensitive materials like sintering or advanced synthesis, our strong deep customization capability can design a solution to precisely meet your experimental requirements.

Contact us today to discuss how a KINTEK furnace can optimize your process and save you valuable time.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide