In essence, modern control systems transform a custom vacuum furnace from a simple heating chamber into an intelligent, automated, and highly efficient manufacturing asset. They enhance operations by enabling precise process automation, ensuring repeatable results through user-defined recipes, providing comprehensive data for quality control, and optimizing energy consumption to lower operational costs.

The core function of an advanced control system is to remove variability. By systematically managing every critical parameter—from temperature ramps to gas pressure—it ensures that every production cycle is an exact replica of the last, turning an artisan process into a reliable industrial one.

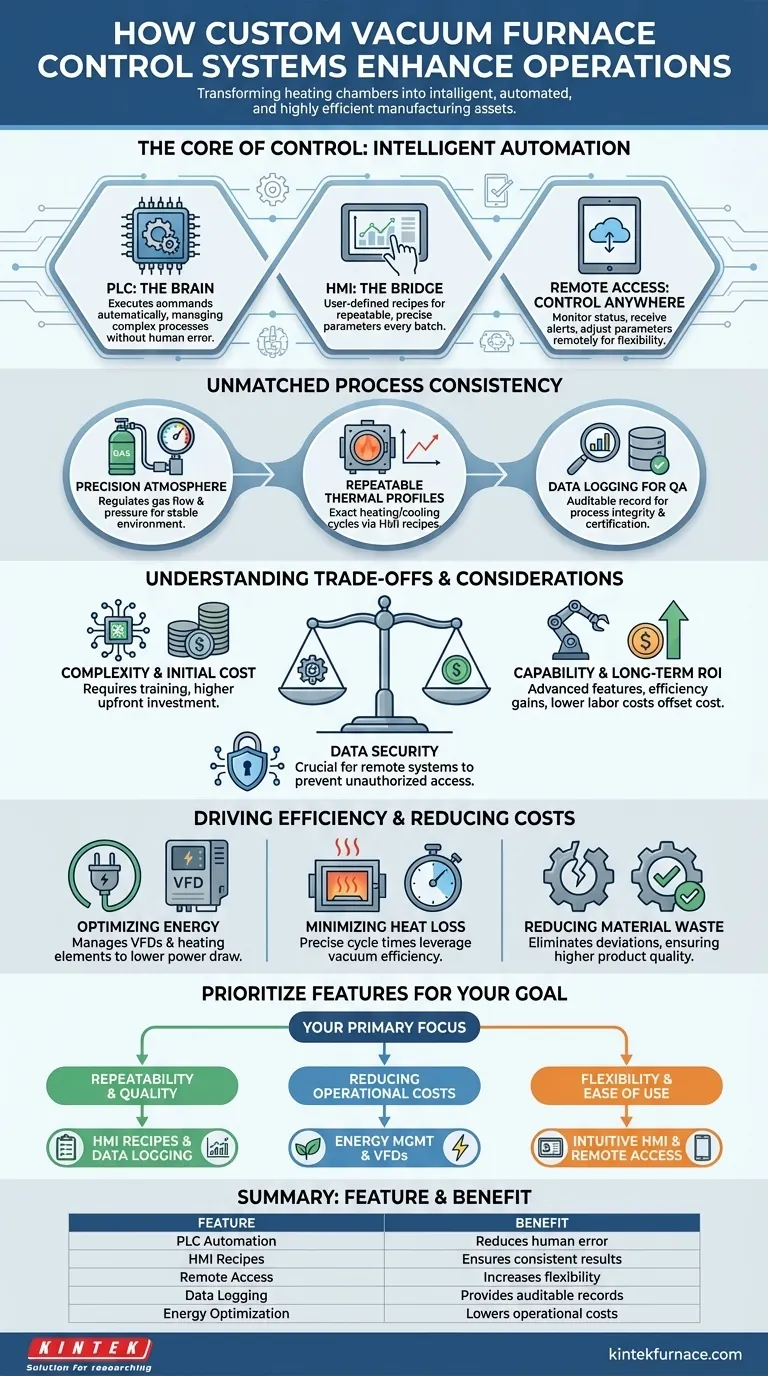

The Core of Control: From Manual to Automated

The foundation of a modern vacuum furnace's performance is its control system. This system acts as the central nervous system, coordinating all functions to achieve a specific, repeatable outcome.

PLC: The Brain of the Operation

A Programmable Logic Controller (PLC) is the industrial computer at the heart of the system. It executes commands automatically, managing everything from valve positions to heating element power. This removes the potential for human error in complex, multi-stage processes.

HMI: The Bridge to the Operator

The Human-Machine Interface (HMI) provides an intuitive graphical display for operators. Through the HMI, users can create, store, and launch specific user-defined process recipes, ensuring that the exact same parameters are used for every batch.

Remote Access: Control from Anywhere

Modern systems often include remote control capabilities. This allows operators and engineers to monitor process status, receive alerts, and even adjust parameters using a computer or mobile device, increasing operational flexibility and response time.

Achieving Unmatched Process Consistency

The primary goal of a sophisticated control system is to guarantee that the material treatment process is stable and perfectly repeatable.

Precision Atmosphere Control

For processes requiring specific gas environments, the control system is critical. It uses sensors and controllers to precisely regulate gas flow rates, mixtures, and pressure levels, creating an exceptionally stable processing environment.

Repeatable Thermal Profiles

Through the HMI recipes, operators define the exact heating rates, soak times, and cooling profiles. The PLC then executes this thermal profile flawlessly, ensuring every part experiences the identical heat treatment cycle.

Data Logging for Quality Assurance

Control systems continuously monitor and store all critical process data. This information can be exported for analysis, providing an auditable record that validates process integrity and is essential for quality assurance and certification.

Understanding the Trade-offs and Considerations

While powerful, advanced control systems come with factors that must be weighed carefully. True expertise lies in understanding these balances.

Complexity vs. Capability

A highly capable system is inherently more complex. Operators and maintenance staff require proper training to leverage the full potential of the system and to troubleshoot effectively.

Initial Cost vs. Long-Term ROI

Furnaces with advanced control systems carry a higher upfront investment. This cost, however, is often quickly offset by long-term returns from increased energy efficiency, reduced scrap rates, and lower labor costs due to automation.

Data Security for Remote Systems

Enabling remote access opens up a potential vector for security breaches. It is crucial to implement robust network security measures to protect the control system from unauthorized access.

Driving Efficiency and Reducing Operational Costs

A key benefit of a well-integrated control system is its direct impact on the bottom line through significant efficiency gains.

Optimizing Energy Consumption

Controls manage energy-saving technologies like Variable Frequency Drives (VFDs), which optimize the power draw of pumps and fans. They also ensure the most efficient use of advanced heating elements and insulation materials.

Minimizing Heat Loss

By precisely managing cycle times, the system leverages the inherent efficiency of the vacuum environment, which minimizes heat loss through convection. In multiple-chamber designs, controls ensure that heat is used exclusively for the parts, avoiding the need to reheat the entire chamber for each load.

Reducing Material Waste

Process consistency directly translates to higher product quality and fewer rejected parts. By eliminating process deviations, control systems dramatically reduce material waste and the associated costs of rework or scrap.

How to Prioritize Control Features for Your Goal

The ideal control system configuration depends entirely on your specific operational priorities.

- If your primary focus is process repeatability and quality assurance: Invest in a system with robust HMI recipe management and comprehensive, easily exportable data logging.

- If your primary focus is reducing operational costs: Prioritize controls that integrate with VFDs and manage energy usage, especially in multi-chamber furnace configurations.

- If your primary focus is operational flexibility and ease of use: Look for systems with an intuitive HMI, extensive recipe storage, and secure remote access capabilities for off-site monitoring.

Ultimately, integrating the right control system elevates your heat treatment process from a cost center to a distinct competitive advantage.

Summary Table:

| Feature | Benefit |

|---|---|

| PLC Automation | Reduces human error and ensures precise execution of complex processes |

| HMI Recipes | Enables user-defined parameters for consistent, repeatable results |

| Remote Access | Allows monitoring and adjustments from anywhere, increasing flexibility |

| Data Logging | Provides auditable records for quality assurance and certification |

| Energy Optimization | Uses VFDs and efficient designs to lower operational costs |

Ready to elevate your heat treatment with intelligent control systems? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and repeatability. Contact us today to discuss how we can optimize your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the common heating methods used in vacuum furnaces? Choose the Best for Your Materials

- What are the key features that make horizontal hinged vacuum furnaces popular? Unlock Precision and Accessibility for Your Lab

- What are the advantages of using heat treatment and vacuum furnaces? Achieve Superior Material Quality and Control

- What types of atmospheres can be used in vacuum heat treatment furnaces? Optimize Your Material Properties

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What additional capabilities do laboratory vacuum furnaces offer besides high-temperature heating? Unlock Precision Control for Advanced Materials

- How are vacuum furnaces applied in semiconductor manufacturing? Essential for Purity and Precision in Chip Fabrication

- Why is vacuum brazing particularly suitable for aerospace applications? Achieve Strong, Pure Joints for Critical Components