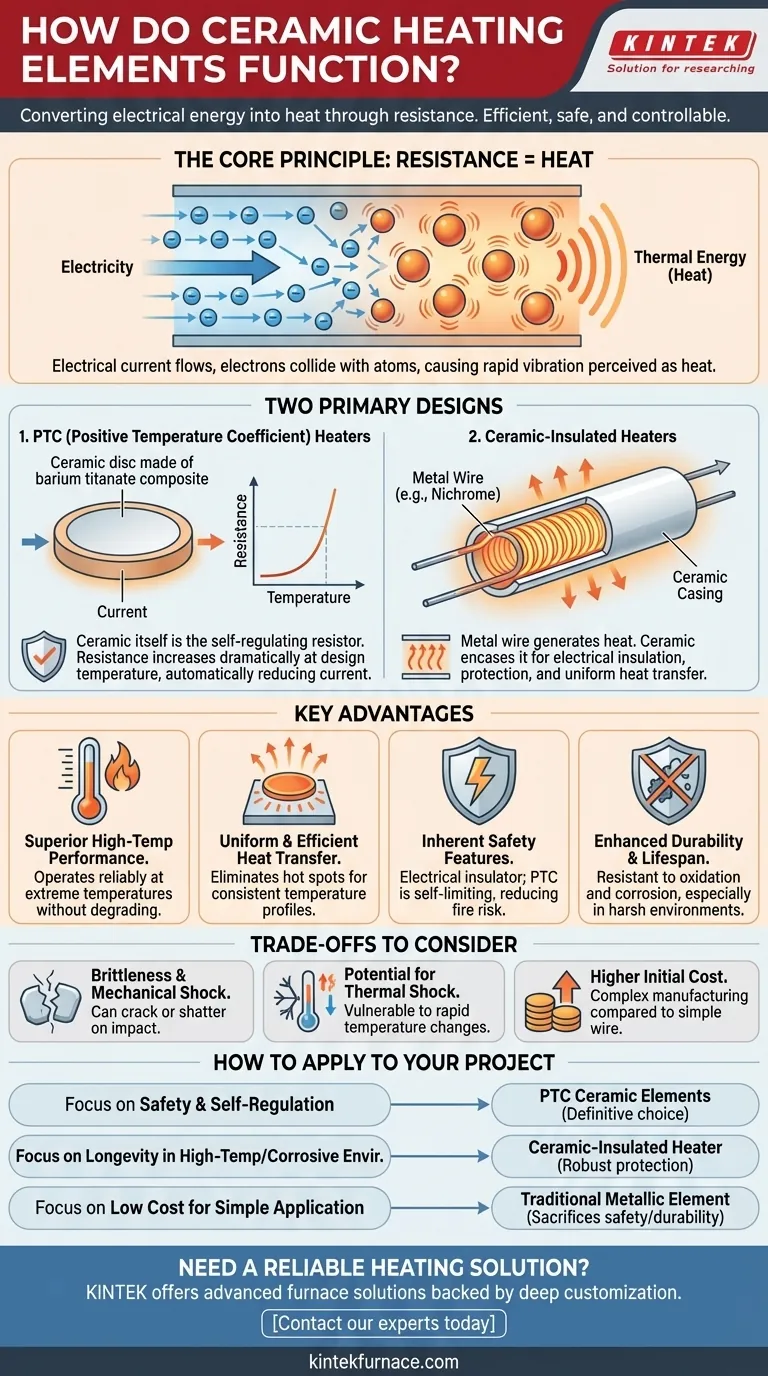

At their core, ceramic heating elements function by converting electrical energy into heat through the principle of electrical resistance. Electricity is passed through a specialized component that resists its flow, and this opposition forces the electrical energy to dissipate as thermal energy. The unique properties of the ceramic material make this process highly efficient, safe, and controllable.

The true value of ceramic heaters isn't just that they produce heat, but how they manage it. They leverage ceramic's natural resistance to high temperatures, corrosion, and electricity to deliver stable, uniform, and safe heating in applications where traditional metallic elements would falter.

The Core Principle: How Resistance Becomes Heat

The fundamental mechanism is simple, but the material science is what makes ceramic heaters exceptional. The process relies on a few key interactions between electricity and the ceramic material.

Converting Electricity into Thermal Energy

All resistive heaters operate on the same principle. When an electrical current flows through a material, the electrons in the current collide with the atoms of the material. In a resistive material, these collisions are frequent and intense, causing the atoms to vibrate rapidly. This atomic vibration is what we perceive as heat.

The Two Roles of Ceramic

The term "ceramic heater" can refer to two primary designs, distinguished by the role the ceramic plays.

-

Positive Temperature Coefficient (PTC) Heaters: In this advanced design, the ceramic material itself—often a barium titanate composite—acts as the resistor. These "stones" or "discs" are semiconductors with a unique self-regulating property. As they heat up to a designed temperature, their electrical resistance increases dramatically, which automatically reduces the current and stops them from getting hotter.

-

Ceramic-Insulated Heaters: In this more common design, a traditional metallic resistance wire (like nichrome) generates the heat. The ceramic component encases this wire, acting as a superb thermal conductor to transfer heat to the air or a surface, and as an excellent electrical insulator to ensure safety. It protects the wire from oxidation and corrosion while distributing its heat evenly.

Why Choose Ceramic? Key Advantages Explained

Engineers and designers specify ceramic heating elements for applications that demand more than just raw heat. Their advantages solve specific challenges that metallic elements cannot.

Superior High-Temperature Performance

Ceramic materials possess much higher melting points than most metals used in heating elements. This allows them to operate reliably at extreme temperatures without degrading, oxidizing, or deforming over time.

Uniform and Efficient Heat Transfer

Ceramics are excellent at conducting and radiating heat evenly across their entire surface. This eliminates the "hot spots" common with bare wire elements, making them ideal for applications requiring consistent and precise temperature profiles, such as in packaging machinery or soldering equipment.

Inherent Safety Features

Ceramic is a natural electrical insulator, which drastically reduces the risk of electric shock. Furthermore, PTC ceramic elements are self-limiting; they cannot overheat beyond their designed threshold, which minimizes fire risk and makes them exceptionally safe for use in consumer appliances like portable space heaters.

Enhanced Durability and Lifespan

Because ceramic is highly resistant to oxidation and chemical corrosion, it offers a significantly longer service life, especially in harsh industrial environments or applications like water heaters where mineral buildup and rust are concerns.

Understanding the Trade-offs

While powerful, ceramic technology is not without its considerations. Objectivity requires acknowledging its limitations.

Brittleness and Mechanical Shock

Unlike ductile metals that can bend, ceramic is brittle. A sharp impact or significant drop can cause a ceramic element to crack or shatter, leading to immediate failure. They must be handled with more care during installation and operation.

Potential for Thermal Shock

While designed for high temperatures, some ceramic types can be susceptible to thermal shock—cracking caused by extremely rapid temperature changes. Proper system design involves managing heat-up and cool-down rates to mitigate this risk.

Cost and Complexity

The manufacturing process for advanced ceramic components is more complex and expensive than simply drawing a metallic wire. This can result in a higher initial cost for ceramic heating elements compared to their simpler metallic counterparts.

How to Apply This to Your Project

Your choice of heating technology should be driven by the specific demands of your application.

- If your primary focus is safety and self-regulation: PTC ceramic elements are the definitive choice, as they physically cannot overheat past their design temperature.

- If your primary focus is longevity in a high-temperature or corrosive environment: A ceramic-insulated heater will protect the resistive element and far outlast an exposed metallic one.

- If your primary focus is low cost for a simple, protected application: A traditional metallic element may suffice, but you will be sacrificing the superior safety, efficiency, and durability of a ceramic design.

By understanding these core properties, you can confidently select the heating technology that best aligns with your project's demands for performance, reliability, and safety.

Summary Table:

| Feature | PTC Ceramic Heaters | Ceramic-Insulated Heaters |

|---|---|---|

| Primary Function | Ceramic material acts as self-regulating resistor | Ceramic casing insulates and protects a metal heating wire |

| Key Advantage | Inherent safety; cannot overheat | Excellent durability in high-temp/corrosive environments |

| Ideal For | Applications where safety is paramount | Applications requiring longevity and uniform heat distribution |

Need a reliable, high-performance heating solution for your lab or industrial process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Whether your application requires the self-regulating safety of PTC ceramics or the robust protection of a ceramic-insulated element, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact our experts today to discuss how we can design the perfect heating solution for you.

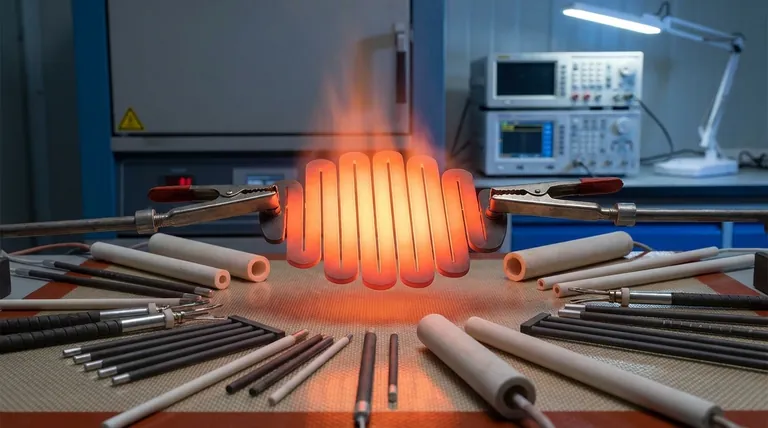

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability