To accelerate diamond growth in a Microwave Plasma Chemical Vapor Deposition (MPCVD) system, you must increase the input microwave power and the chamber pressure. These two parameters directly intensify the plasma environment, which increases the concentration and activity of the carbon-containing atomic groups and hydrogen atoms responsible for building the diamond crystal.

The core challenge of accelerating diamond growth is not merely increasing speed, but managing the unavoidable trade-off between growth rate and crystal quality. While higher power and pressure boost speed, they also risk introducing defects and non-diamond carbon structures into the crystal lattice.

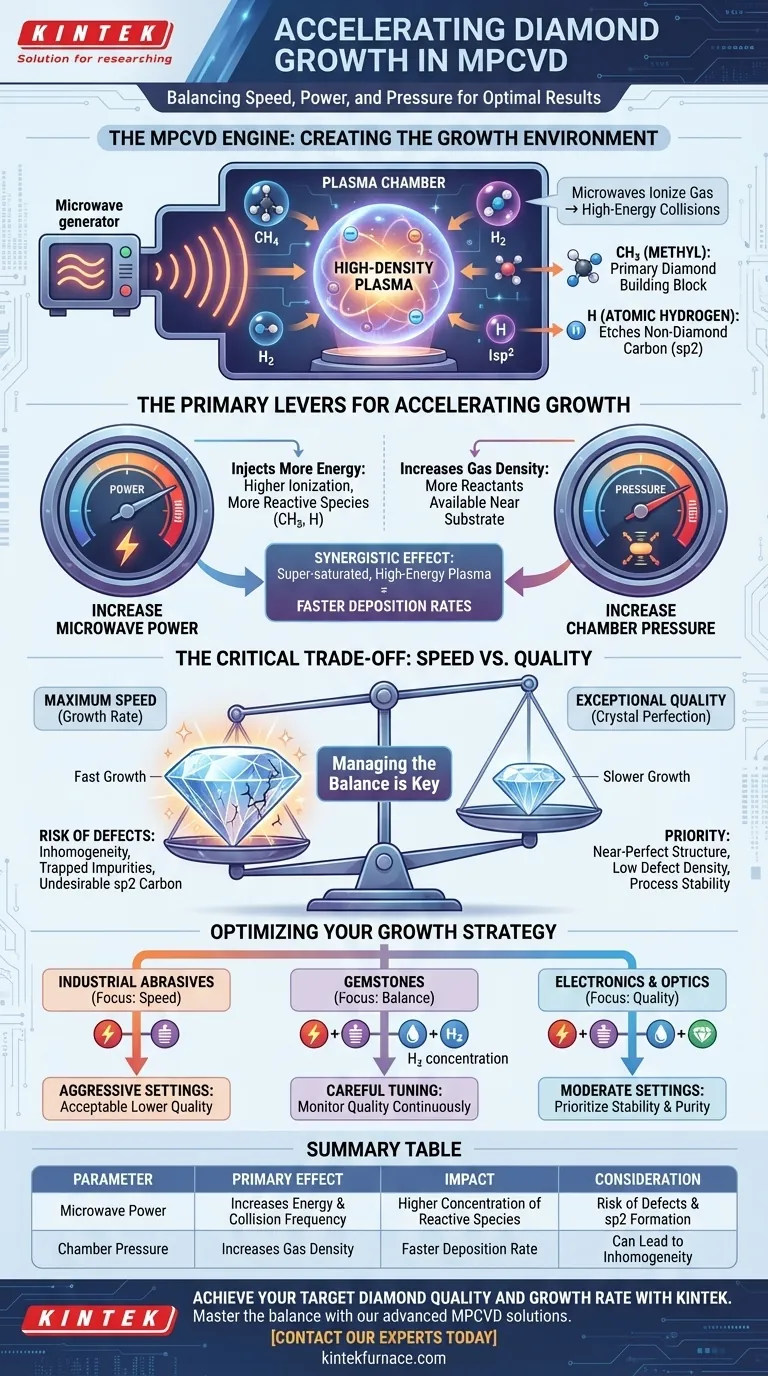

The Engine of MPCVD: Creating the Growth Environment

To control growth speed, you must first understand the fundamental mechanics of the plasma that builds the diamond. MPCVD is a process of controlled energy and chemistry.

How Microwaves Generate Plasma

The process begins when microwaves energize a reaction gas (typically a mix of methane and hydrogen) inside a vacuum chamber. This energy strips electrons from atoms, creating a glowing ball of ionized gas known as plasma.

The intense electromagnetic field from the microwaves causes these free electrons to oscillate violently, leading to a cascade of high-energy collisions between all atoms and molecules in the chamber. This creates a high-density, highly reactive plasma state essential for diamond deposition.

The Key Chemical Actors: Carbon and Hydrogen

Within this plasma, two critical processes occur simultaneously. First, methane molecules (CH4) break down into reactive carbon-containing groups like methyl (CH3). These are the primary building blocks for the diamond.

Second, hydrogen gas (H2) breaks down into highly reactive atomic hydrogen (H). This atomic hydrogen performs a crucial dual role: it stabilizes the diamond surface to accept new carbon atoms and, more importantly, it preferentially etches away any non-diamond carbon, like graphite (sp2), that may form.

The Primary Levers for Accelerating Growth

With a clear understanding of the plasma environment, the methods for accelerating growth become intuitive. You are essentially turning up the energy and density of the system.

Increasing Microwave Power

Higher microwave power injects more energy into the plasma. This leads to a higher degree of gas ionization and more frequent, energetic collisions. The direct result is a more efficient breakdown of methane and hydrogen, increasing the concentration of the essential CH3 building blocks and atomic hydrogen etchants.

Increasing Chamber Pressure

Higher pressure forces more gas molecules into the same volume. This increases the overall density of the reaction gas, providing more raw material for the plasma to act upon. A denser gas environment means a higher concentration of reactants is available near the diamond substrate, directly promoting a faster deposition rate.

The Synergistic Effect

Power and pressure work in tandem. Increasing both simultaneously creates a super-saturated, high-energy plasma packed with the reactive species needed for rapid growth. This combination is how modern MPCVD systems can achieve growth rates exceeding 100 μm/h.

Understanding the Critical Trade-off: Speed vs. Quality

Accelerating the growth rate is not without significant consequences. Pushing the system for maximum speed directly compromises the perfection of the diamond crystal.

The Cost of Speed: Defects and Inhomogeneity

As the growth rate skyrockets, the carefully ordered, atom-by-atom deposition process can become chaotic. This can lead to structural defects, impurities being trapped in the crystal lattice, and less homogeneity across the surface of the diamond. The resulting diamond may have limited usable area and be unsuitable for high-precision applications.

The Quality Problem: Undesirable Carbon (sp2)

The primary reason for a drop in quality is the race between diamond (sp3) growth and non-diamond (sp2) graphite formation. At very high growth rates, the deposition of carbon can outpace the ability of atomic hydrogen to selectively etch away the undesirable graphite. If the balance is lost, sp2 carbon becomes locked into the crystal, degrading its quality.

High-Purity Applications

For demanding applications like semiconductors, optics, or quantum sensors, crystal quality is paramount. These fields require near-perfect diamonds with extremely low defect density and impurity content. In these cases, growth rates are often deliberately moderated to ensure perfection, and operators focus on high-purity raw materials and ultra-reliable vacuum systems.

Optimizing Your Growth Strategy

The correct approach depends entirely on the intended application of the final diamond product. There is no single "best" setting, only the right balance for your specific goal.

- If your primary focus is maximum growth rate (e.g., for industrial abrasives): You can aggressively increase microwave power and chamber pressure, as lower crystal quality and homogeneity are often acceptable.

- If your primary focus is exceptional quality (e.g., for electronics or high-end optics): You should use moderate power and pressure settings, prioritizing process stability and gas purity over raw speed.

- If your primary focus is a balanced outcome (e.g., for quality gemstones): You must carefully increase power and pressure while continuously monitoring crystal quality, potentially using slightly higher hydrogen concentrations to aid the etching of non-diamond carbon.

Mastering MPCVD is a matter of precisely balancing the creative force of carbon deposition with the refining action of hydrogen etching.

Summary Table:

| Parameter to Increase | Primary Effect on Plasma | Impact on Diamond Growth | Key Consideration |

|---|---|---|---|

| Microwave Power | Increases energy, ionization, and collision frequency | Higher concentration of reactive carbon (CH3) and hydrogen (H) species | Higher risk of defects and non-diamond carbon (sp2) formation |

| Chamber Pressure | Increases gas density and reactant concentration | Faster deposition rate due to more available reactants near the substrate | Can lead to inhomogeneity and reduced crystal quality |

Achieve Your Target Diamond Quality and Growth Rate with KINTEK

Mastering the balance between speed and perfection in MPCVD is complex. Whether your goal is maximum growth for industrial abrasives or flawless crystals for semiconductors, the right equipment is critical.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you optimize your process. Contact our experts today to discuss how our tailored MPCVD solutions can accelerate your research and production.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity