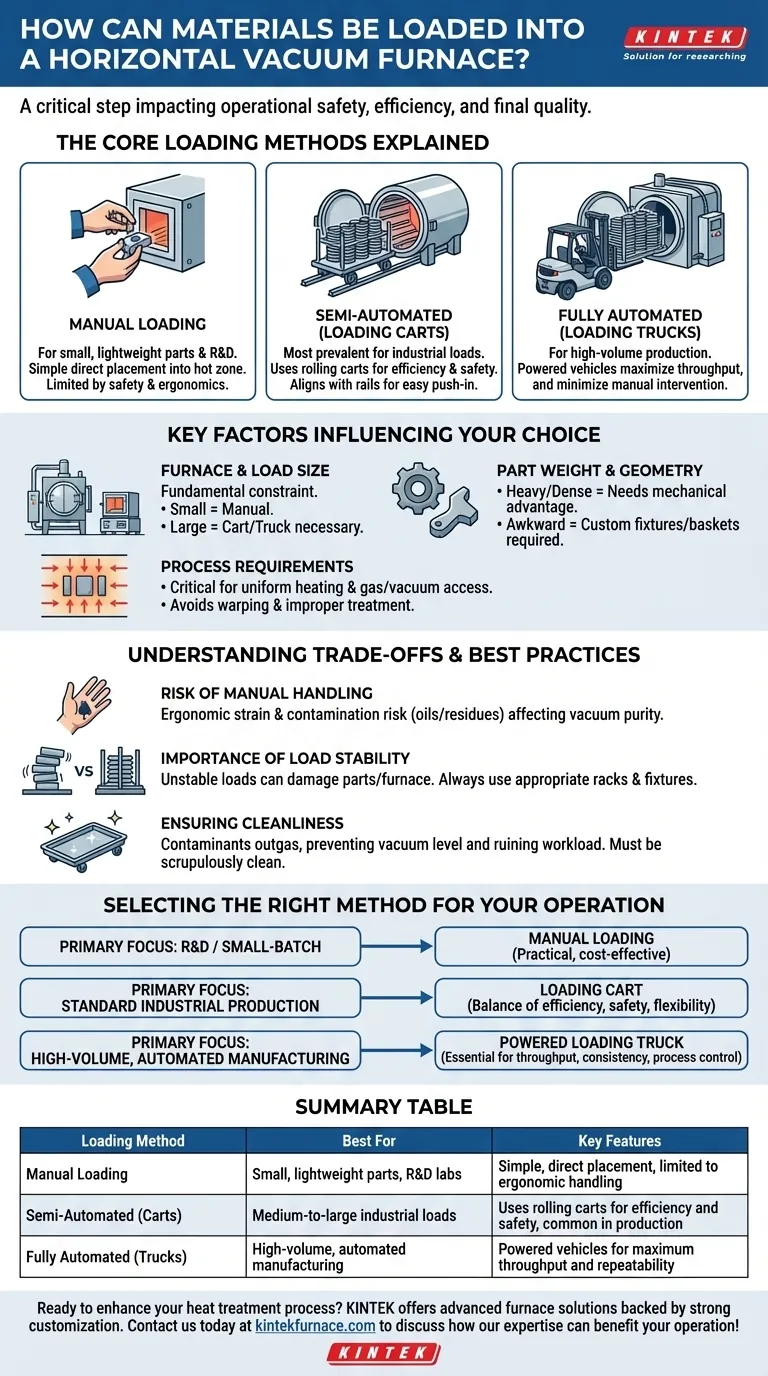

In practice, a horizontal vacuum furnace is loaded using one of three primary methods: by hand, with a rolling loading cart, or with a dedicated loading truck. The correct method depends entirely on the size of the furnace, the weight and dimensions of the parts being processed, and the required production throughput.

Choosing a loading method is not just a logistical decision; it is a critical process step that directly impacts operational safety, efficiency, and the final quality of the heat-treated components.

The Core Loading Methods Explained

The physical act of loading a furnace ranges from simple manual placement to fully automated systems. Understanding each method's context is key to optimizing your heat treatment operations.

Manual Loading

For very small, laboratory-scale furnaces or lightweight, individual parts, manual loading is common. An operator simply places the material or a small tray directly into the furnace's hot zone by hand.

This method is the most straightforward but is limited to situations where the parts are small and light enough to be handled safely and ergonomically.

Semi-Automated Loading (Loading Carts)

The most prevalent method for industrial horizontal furnaces involves a loading cart. These carts are equipped with casters or wheels that align with rails leading into the furnace.

Parts are arranged on fixtures, trays, or racks, which are then placed onto the cart. The operator rolls the entire assembly up to the furnace, aligns it with the chamber, and pushes the load inside. This dramatically improves efficiency and safety for medium-to-large loads.

Fully Automated Loading (Loading Trucks)

In high-volume production environments, a fully automated loading truck is used. This is a powered vehicle designed specifically to interface with one or more furnaces.

The loader retrieves a prepared rack of parts, transports it to the correct furnace, automatically opens the door, and precisely inserts the load. This method maximizes throughput, ensures repeatability, and minimizes manual intervention.

Key Factors Influencing Your Loading Choice

Selecting the right method goes beyond the furnace door. It requires considering the entire process from start to finish.

Furnace and Load Size

This is the most fundamental constraint. A small benchtop furnace dictates manual loading, while a multi-ton industrial furnace makes a loading cart or truck non-negotiable. The overall volume and footprint of your workload define the necessary equipment.

Part Weight and Geometry

Heavy, dense loads require the mechanical advantage of a cart or truck to ensure operator safety and prevent damage to the furnace hearth. Awkwardly shaped parts may need custom fixtures or baskets to keep them stable during loading and throughout the heat treat cycle.

Process Requirements

Proper loading is critical for a successful metallurgical outcome. Parts must be arranged to ensure uniform heating and adequate access for process gases or vacuum pump-down. For processes like vacuum sintering or annealing, incorrect spacing can lead to parts touching, warping, or receiving non-uniform treatment.

Understanding the Trade-offs and Best Practices

An effective loading strategy mitigates risk and ensures process integrity. Ignoring these factors can lead to failed cycles, damaged equipment, or safety incidents.

The Risk of Manual Handling

Even when a furnace is at room temperature, manual loading carries risks. It introduces potential ergonomic strain and increases the chance of contaminating parts with oils or residues from hands, which can compromise vacuum purity.

The Importance of Load Stability

A load that is unstable can shift or collapse during insertion or the heating cycle. This can damage the parts, the furnace's heating elements, or the hearth assembly. Always use appropriate racks and fixtures to secure the load.

Ensuring Cleanliness

Anything that enters the vacuum chamber—including trays, fixtures, and the loading cart itself—must be scrupulously clean. Dirt, grease, or other contaminants will outgas during the cycle, preventing the furnace from reaching the required vacuum level and potentially contaminating the workload.

Selecting the Right Method for Your Operation

Base your decision on the primary goal of your heat treatment department.

- If your primary focus is R&D or small-batch processing: Manual loading of parts onto a clean tray is often the most practical and cost-effective approach.

- If your primary focus is standard industrial production: A dedicated rolling loading cart offers the best balance of efficiency, safety, and operational flexibility.

- If your primary focus is high-volume, automated manufacturing: Investing in a powered loading truck is essential for maintaining throughput, consistency, and process control.

Ultimately, a deliberate loading strategy is the foundation of a safe, efficient, and repeatable heat treatment process.

Summary Table:

| Loading Method | Best For | Key Features |

|---|---|---|

| Manual Loading | Small, lightweight parts, R&D labs | Simple, direct placement, limited to ergonomic handling |

| Semi-Automated (Loading Carts) | Medium-to-large industrial loads | Uses rolling carts for efficiency and safety, common in production |

| Fully Automated (Loading Trucks) | High-volume, automated manufacturing | Powered vehicles for maximum throughput and repeatability |

Ready to enhance your heat treatment process with the right loading solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're in R&D, industrial production, or high-volume manufacturing, we can help you achieve superior safety, efficiency, and quality. Contact us today to discuss how our expertise can benefit your operation!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing