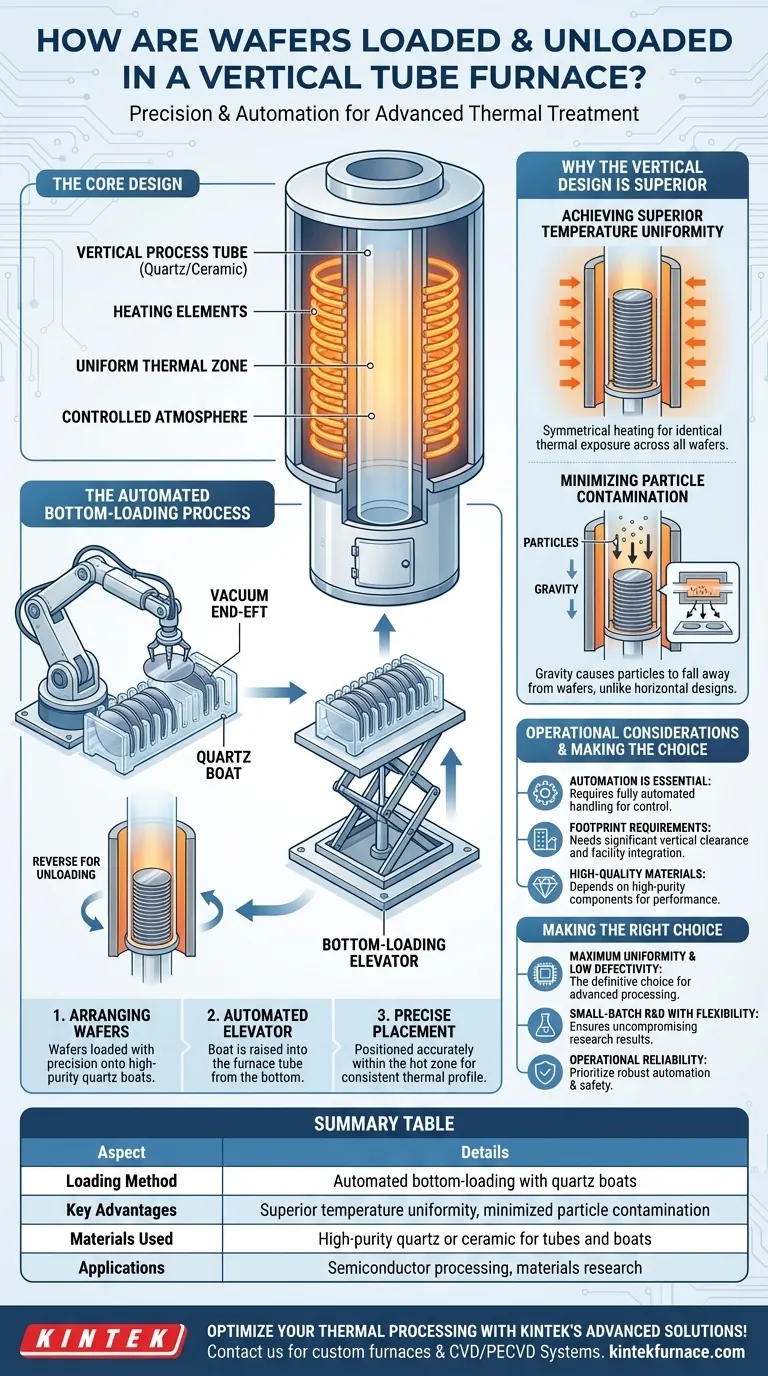

In a vertical tube furnace, silicon wafers are first arranged onto specialized quartz carriers, known as "boats." These boats are then mechanically loaded and unloaded as a complete unit from the bottom of the vertically oriented process tube, allowing for a highly controlled and automated thermal treatment process.

The bottom-loading mechanism of a vertical furnace is not merely a convenience; it is a deliberate engineering choice driven by the need for superior temperature uniformity and the minimization of particle contamination, which are critical for high-yield manufacturing.

The Core Design of a Vertical Furnace

To understand the loading process, we must first understand the furnace's fundamental architecture. It is designed from the ground up for precision and consistency.

The Vertical Process Tube

At the heart of the furnace is a vertically oriented tube, typically made of high-purity materials like quartz or ceramic. This tube contains the controlled atmosphere where the wafers will be heated.

Surrounding Heating Elements

The process tube is encased by resistive heating elements. These elements generate radiant heat, which is distributed evenly along the length of the tube to create a stable and uniform thermal zone.

The Controlled Atmosphere

The entire process occurs in a sealed environment. This allows for precise control over the gas composition, pressure, and flow, preventing oxidation or other unwanted chemical reactions during heat treatment.

The Loading and Unloading Process Explained

The movement of wafers into and out of this environment is a carefully choreographed, automated procedure.

Step 1: Arranging Wafers on Quartz Boats

Wafers are carefully placed with robotic precision into slots on a quartz boat. Quartz is used for its exceptional thermal stability and high purity, ensuring it does not become a source of contamination at extreme temperatures.

Step 2: The Automated Bottom-Loading Elevator

The entire boat is positioned on an elevator mechanism located directly beneath the furnace tube. The bottom of the tube is sealed with a door that opens to allow the elevator to raise the boat up into the furnace.

Step 3: Precise Placement in the Hot Zone

The automated system lifts the boat into the center of the pre-heated thermal zone. This slow, controlled movement prevents thermal shock to the wafers and ensures the entire batch is positioned identically for every run, guaranteeing process repeatability. Unloading is the reverse of this process.

Why This Vertical Design is Superior

The bottom-loading vertical architecture directly solves critical challenges faced by older, horizontal furnace designs.

Achieving Superior Temperature Uniformity

By stacking wafers vertically within a symmetrical heating column, every wafer in the boat is exposed to a nearly identical thermal profile. This eliminates the temperature gradients often seen in horizontal tubes, where wafers at the front, back, or bottom can experience different conditions.

Minimizing Particle Contamination

This is a critical advantage. In a horizontal furnace, particles flaking off the top of the process tube can fall directly onto the wafers below. In a vertical furnace, gravity works in your favor; any potential particles are far more likely to fall straight down, past the wafers, and out of the critical process area.

Ensuring Stability and Process Control

The automated elevator system provides exceptionally smooth and repeatable motion. This, combined with a modern control interface, simplifies operation and reduces the chance of human error, enhancing both efficiency and safety.

Understanding the Operational Considerations

While superior, the vertical furnace design comes with its own set of characteristics that must be managed.

Automation is Not Optional

The precision required for loading and the design of the system necessitate a fully automated handling mechanism. This increases system complexity but is fundamental to achieving the process control benefits.

Footprint and Facility Requirements

Vertical furnaces are tall and require significant vertical clearance. They are substantial pieces of equipment that must be integrated into a facility's infrastructure, often requiring placement in a cleanroom bay.

Importance of High-Quality Materials

The entire system's performance relies on the quality of its components. The process tube and wafer boats must be made from the highest-purity materials to prevent them from degrading and introducing defects at high temperatures.

Making the Right Choice for Your Process

The loading mechanism is a key indicator of the furnace's intended application and performance level.

- If your primary focus is maximum process uniformity and low defectivity: The automated bottom-loading vertical furnace is the definitive choice for advanced semiconductor and materials processing.

- If your primary focus is small-batch R&D with a flexible budget: A vertical furnace still offers the best results, ensuring your research is not compromised by equipment limitations.

- If your primary focus is operational reliability: Prioritize a system from a reputable manufacturer with a proven, robust automation platform and comprehensive safety interlocks.

Ultimately, the vertical furnace's loading method is a direct reflection of its core purpose: achieving uncompromising precision and quality in high-stakes thermal processing.

Summary Table:

| Aspect | Details |

|---|---|

| Loading Method | Automated bottom-loading with quartz boats |

| Key Advantages | Superior temperature uniformity, minimized particle contamination |

| Materials Used | High-purity quartz or ceramic for tubes and boats |

| Applications | Semiconductor processing, materials research |

Optimize your thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and yield. Contact us today to discuss how we can support your high-stakes applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation