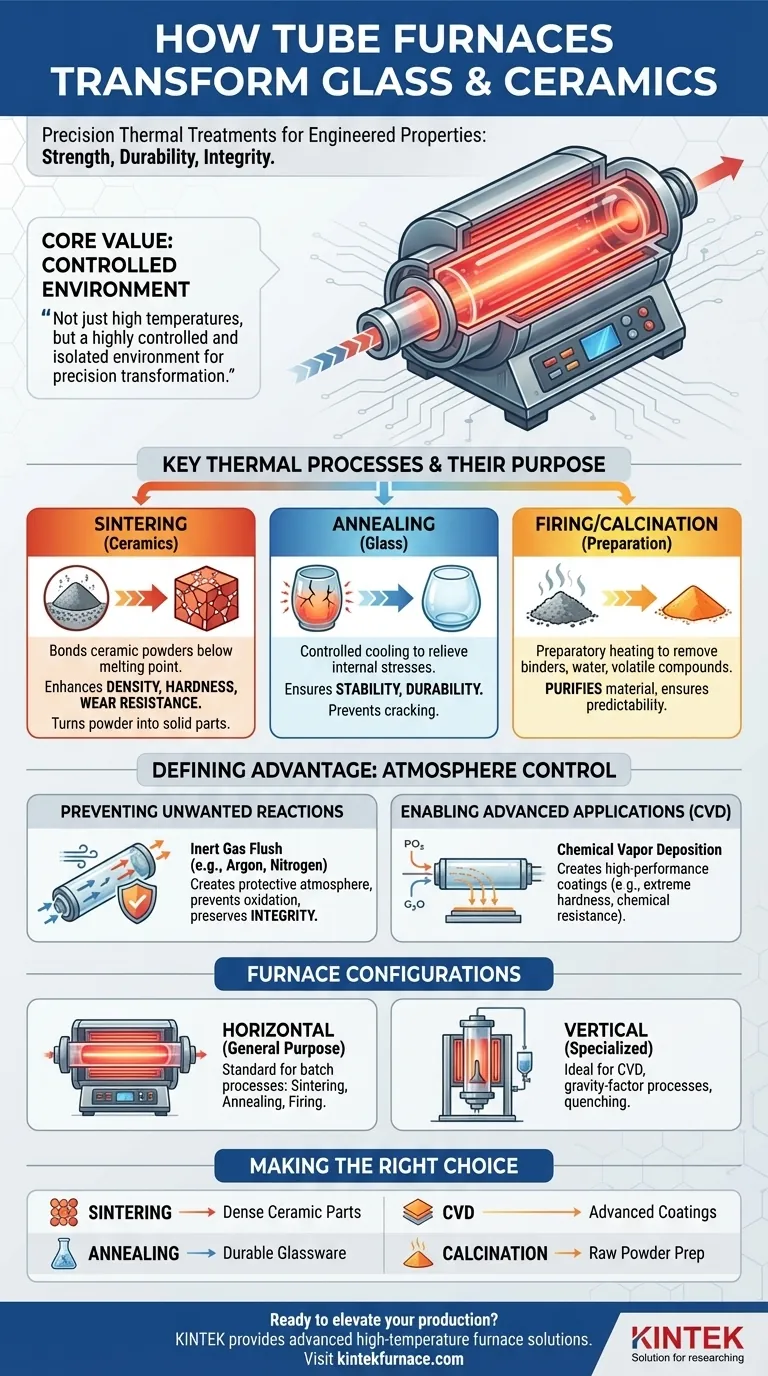

In the glass and ceramics industry, a tube furnace is a precision instrument for executing critical high-temperature thermal treatments. These processes, including sintering, annealing, and firing, are not just about heating; they are about fundamentally transforming raw materials into finished components with specific, engineered properties like superior strength, durability, and structural integrity.

The core value of a tube furnace lies not merely in its ability to generate high temperatures, but in its capacity to create a highly controlled and isolated environment. This precision is what enables the transformation of basic materials into high-performance glass and ceramic products.

Key Thermal Processes and Their Purpose

A tube furnace's primary function is to apply a precise thermal cycle to a material. In glass and ceramics, this is used to drive specific physical and chemical changes.

Sintering: Forging Strength in Ceramics

Sintering is a process where ceramic powders are heated to a temperature just below their melting point.

This high-temperature treatment causes the individual particles to bond together, which significantly enhances the material's density, hardness, and wear resistance. It's the fundamental process for turning a compacted powder into a solid, robust ceramic part.

Annealing: Ensuring Stability in Glass

After glass is formed, it cools unevenly, creating internal stresses that can cause it to crack or shatter unexpectedly.

Annealing involves reheating the glass to a specific temperature and then cooling it very slowly under controlled conditions. This process relieves the internal stresses, resulting in a much more durable and stable final product.

Firing and Calcination: Preparing Raw Materials

Before the final high-temperature step, materials often undergo preparatory heating.

Firing and calcination are used to drive off water, decompose organic binders, or induce preliminary chemical reactions. This purifies the material and ensures it behaves predictably during the final sintering or melting stage.

The Defining Advantage: Precise Atmosphere Control

The tube furnace's sealed design is its most critical feature, allowing for complete control over the gaseous environment surrounding the sample. This is non-negotiable for achieving desired material outcomes.

Preventing Unwanted Reactions

Many materials will oxidize or react with air at high temperatures, which can ruin their properties.

By flushing the tube with an inert gas (like argon or nitrogen), a tube furnace creates a protective atmosphere that prevents these unwanted chemical reactions, preserving the material's integrity.

Enabling Advanced Applications

This control also enables advanced processes like Chemical Vapor Deposition (CVD). In CVD, precursor gases are introduced into the furnace, where they react and deposit a thin film onto a substrate.

This technique is used to create high-performance coatings on ceramic components, adding properties like extreme hardness or chemical resistance.

Understanding the Furnace Configurations

Not all tube furnaces are the same. The physical orientation and design are tailored to specific processes, and understanding these differences is key to proper application.

Horizontal vs. Vertical Furnaces

The most common distinction is between horizontal and vertical orientations.

Horizontal tube furnaces are the standard for general-purpose batch processes like annealing, firing, and sintering, where samples are simply placed inside the tube.

Vertical tube furnaces are ideal for processes where gravity is a factor, such as CVD, or for heat-treating samples that must be suspended or dropped into a quenching medium.

Specialized Furnace Designs

For certain advanced materials, specialized furnaces are required. For example, graphite tube furnaces are built specifically for ultra-high-temperature processes involving carbon, such as graphitization or creating carbon nanotubes.

Common Pitfalls to Avoid

A common mistake is assuming any furnace can perform any task. Using an air atmosphere for a material that requires an inert environment will lead to failure. Likewise, the scale is a consideration; tube furnaces are excellent for research, development, and specialized production but are not typically used for mass manufacturing of simple goods, where larger tunnel kilns are more efficient.

Making the Right Choice for Your Goal

The process you choose is dictated entirely by the final properties you need to achieve in your material.

- If your primary focus is creating dense, strong ceramic parts: You will use sintering to bond powder particles together under high, controlled heat.

- If your primary focus is producing durable, stable glassware: You will rely on a precise annealing cycle to remove internal stresses after forming.

- If your primary focus is developing advanced coatings or thin films: You require a furnace with excellent atmosphere control to perform processes like CVD.

- If your primary focus is preparing raw powders for final treatment: You will use calcination or drying to purify the material and remove volatile compounds.

Understanding these core processes empowers you to select the precise thermal treatment needed to engineer your material's final properties.

Summary Table:

| Process | Purpose | Key Benefit |

|---|---|---|

| Sintering | Bond ceramic powders | Increases density and hardness |

| Annealing | Relieve stress in glass | Improves durability and stability |

| Firing/Calcination | Prepare raw materials | Purifies and ensures predictability |

| CVD | Deposit thin films | Adds hardness or chemical resistance |

| Atmosphere Control | Prevent oxidation | Preserves material integrity |

Ready to elevate your glass and ceramics production with tailored thermal solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, delivering superior strength, durability, and efficiency for your materials. Contact us today to discuss how our expertise can transform your processes!

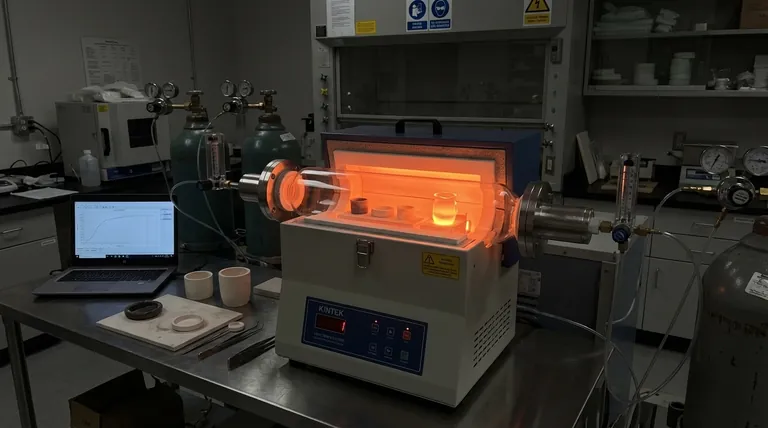

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents