In the aerospace industry, the primary use of muffle furnaces is to perform critical safety testing on materials and components. By exposing parts to precisely controlled, high-temperature environments, engineers can rigorously test for flame retardancy and evaluate the performance of heat-duty materials, ensuring they meet the extreme demands of flight.

The role of a muffle furnace in aerospace extends far beyond simple fire testing. It is a fundamental tool of material science, enabling the development, qualification, and processing of advanced materials where failure under extreme thermal stress is not an option.

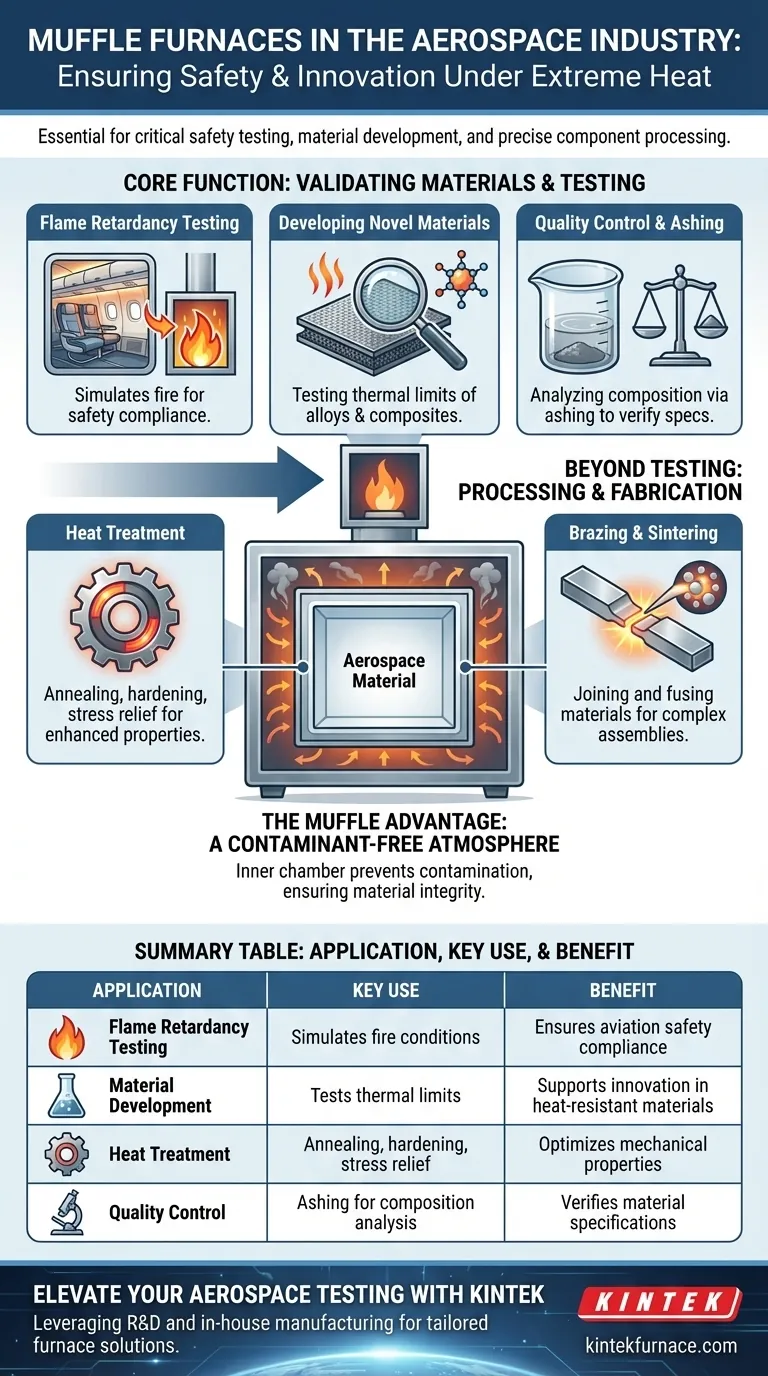

The Core Function: Validating Materials Under Extreme Heat

The defining characteristic of aerospace applications is the need for absolute reliability in harsh environments. Muffle furnaces provide the controlled conditions necessary to validate that materials meet this standard.

Flame Retardancy Testing for Safety Compliance

The most direct and critical application is testing the flame retardancy of interior and structural components. Samples are subjected to extreme heat inside the furnace to simulate fire conditions.

This process is not just for research; it is a mandatory step for certifying that materials used in cabins, cargo holds, and engine compartments comply with strict aviation safety regulations.

Developing Novel Heat-Resistant Materials

Aerospace innovation is driven by material science. Muffle furnaces are indispensable in research and development labs for creating and evaluating new alloys, ceramics, and composites.

Engineers can systematically test how these new materials behave at their thermal limits, providing the data needed to design lighter, stronger, and more heat-resistant aircraft and spacecraft parts.

Quality Control and Component Analysis

Muffle furnaces are used to analyze the composition of materials. By burning off all organic matter in a process called ashing, engineers can determine the proportion of non-combustible material in a composite sample.

This is a vital quality control step to ensure that each batch of material meets the exact specifications required for production.

Beyond Testing: Processing and Fabrication

While testing is a primary function, muffle furnaces are also integral to the manufacturing process itself, used to impart specific properties to finished components.

Heat Treatment for Enhanced Mechanical Properties

Many metal aerospace parts, particularly those made from titanium and other high-strength alloys, undergo heat treatment to achieve their final characteristics.

Processes like annealing (softening), hardening (strengthening), and stress relief are performed in a muffle furnace to alter the material's molecular structure, optimizing it for performance and durability.

Brazing and Sintering

Brazing, a process for joining metal components using a filler metal, is often performed in a furnace to create strong, uniform joints for complex assemblies.

Similarly, sintering uses the furnace's heat to fuse powdered materials, like ceramics or metals, into a solid, high-strength part, a common method for producing components for high-temperature applications.

Understanding the Trade-offs and Limitations

A muffle furnace is a specific tool with distinct advantages and limitations. Understanding these is key to its proper application.

The Muffle's Advantage: A Contaminant-Free Atmosphere

The defining feature of a muffle furnace is its "muffle," an inner chamber that separates the material being heated from the heating elements.

This design prevents contamination from combustion byproducts, ensuring the material's properties are not altered by the heating process itself. It provides an exceptionally clean and controlled environment, which is critical for sensitive aerospace materials.

Limitations in Scale and Process

Standard muffle furnaces are typically suited for testing samples or processing smaller components.

For fabricating very large parts, such as macro-scale carbon composite assemblies or large titanium airframe structures, the industry often turns to specialized large-format retort furnaces or cold wall furnaces that can accommodate the size and processing requirements.

Making the Right Choice for Your Goal

The application of a muffle furnace is directly tied to the engineering objective.

- If your primary focus is safety and certification: The muffle furnace is the industry standard for conducting flame retardancy and material composition tests required by aviation authorities.

- If your primary focus is material development: Use the furnace to precisely test the thermal limits and behavioral properties of new alloys, composites, and ceramics in a controlled environment.

- If your primary focus is component manufacturing: The furnace is essential for critical heat treatments like hardening, annealing, and brazing that determine a part's final performance and reliability.

Ultimately, the muffle furnace acts as a critical gatekeeper, ensuring that only materials proven to withstand the harshest conditions are cleared for flight.

Summary Table:

| Application | Key Use | Benefit |

|---|---|---|

| Flame Retardancy Testing | Simulates fire conditions for materials | Ensures compliance with aviation safety standards |

| Material Development | Tests thermal limits of alloys and composites | Supports innovation in heat-resistant materials |

| Heat Treatment | Performs annealing, hardening, and stress relief | Optimizes mechanical properties of components |

| Quality Control | Conducts ashing for material composition analysis | Verifies material specifications for production |

Ready to elevate your aerospace material testing and processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored furnace solutions can enhance your safety compliance, material innovation, and component reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity