In the ceramics and glass industries, muffle furnaces are indispensable tools used for high-temperature thermal processing. Their primary functions are firing and sintering ceramics to achieve hardness and durability, as well as melting, fusing, and annealing glass to ensure clarity and structural integrity. They are used in both final production and critical quality control testing.

The core value of a muffle furnace lies in its ability to create a highly controlled, contaminant-free heating environment. By separating the material from the heating elements and combustion byproducts, it ensures the chemical purity and physical properties of the final ceramic or glass product.

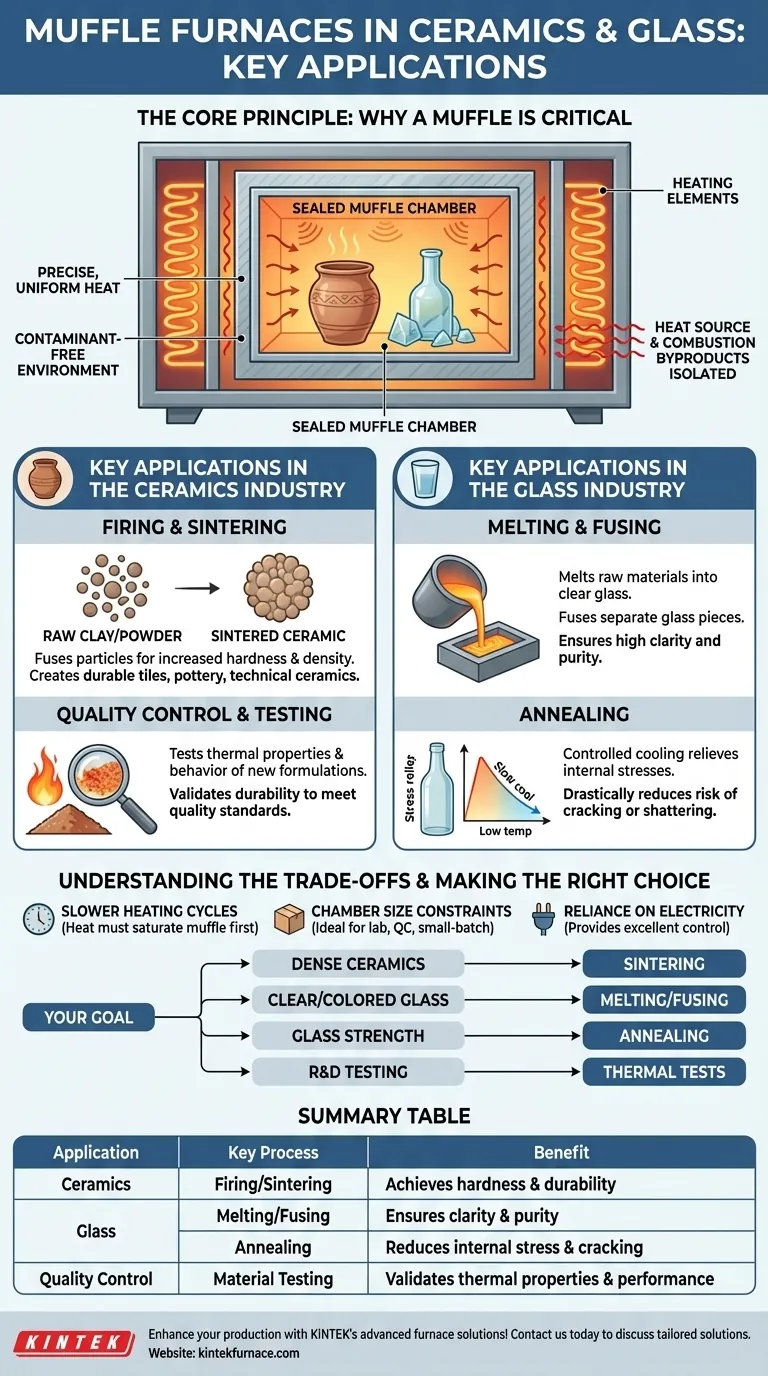

The Core Principle: Why a 'Muffle' is Critical

The defining feature of a muffle furnace is the "muffle" itself—an inner chamber that isolates the workload from the heat source. This design is fundamental to its utility in sensitive applications like ceramics and glass.

A Contaminant-Free Environment

The sealed muffle prevents any byproducts of combustion or particles from the heating elements from coming into contact with the material being processed. This separation is crucial for preventing discoloration in ceramics and ensuring the optical clarity and purity of glass.

Precise and Uniform Heat

The muffle design promotes radiant and convective heating, resulting in exceptionally uniform temperature distribution throughout the chamber. This precision ensures that every part of the workpiece receives the same thermal treatment, which is non-negotiable for achieving consistent, repeatable results.

Key Applications in the Ceramics Industry

Muffle furnaces are essential for transforming raw clay and ceramic powders into strong, functional products.

Firing and Sintering

Firing is the general process of heating clay or ceramic materials to a high temperature to permanently harden them.

Sintering is a specific firing technique where ceramic particles are heated to just below their melting point. This causes the particles to fuse together, reducing porosity and dramatically increasing the material's strength and density. This is the core process for creating durable tiles, pottery, and advanced technical ceramics.

Quality Control and Material Testing

Furnaces are used in laboratory settings to test the thermal properties and behavior of new ceramic formulations. By subjecting samples to extreme heat cycles, manufacturers can validate the durability and performance of their materials, ensuring the final products meet stringent quality standards.

Key Applications in the Glass Industry

For glass, the clean and controlled environment of a muffle furnace is vital for both creation and finishing.

Melting and Fusing

In smaller-scale or specialized production, muffle furnaces are used to melt raw materials like sand and soda ash into molten glass. The contaminant-free atmosphere is essential for achieving high clarity and controlling the color of the final product. They are also used for fusing separate pieces of glass together for artistic or technical purposes.

Annealing

Annealing is a critical finishing step for nearly all glass products. The process involves reheating the glass to a specific temperature and then cooling it down very slowly in a highly controlled manner. This relieves the internal stresses created during manufacturing, drastically reducing the risk of the glass cracking or shattering later.

Understanding the Trade-offs

While highly effective, muffle furnaces have specific characteristics that make them suitable for certain tasks over others.

Slower Heating Cycles

Because the heat must first saturate the muffle before being transferred to the workload, these furnaces can have slower heat-up and cool-down times compared to direct-fired kilns.

Chamber Size Constraints

The muffle design can limit the furnace's internal volume. This makes them ideal for laboratory work, quality control, prototyping, and small-batch production, but less practical for mass-producing very large items.

Reliance on Electricity

Most modern muffle furnaces are electric, relying on a stable power source. While this provides excellent control, it differs from traditional large-scale kilns that may use natural gas or other fuels.

Making the Right Choice for Your Goal

Understanding the specific process enables you to control the final properties of your material.

- If your primary focus is creating dense, durable ceramic bodies: Your key process is sintering, which requires the precise, uniform high temperatures a muffle furnace provides.

- If your primary focus is producing high-clarity or colored glass: You will rely on the furnace for clean melting and fusing, where the muffle's isolation from contaminants is paramount.

- If your primary focus is ensuring glass strength and safety: The critical process is annealing, which uses the furnace's controlled cooling capabilities to remove internal stress.

- If your primary focus is research and development: You will use the furnace to conduct thermal tests on new materials, validating their quality and performance characteristics.

Mastering these applications gives you direct control over the strength, clarity, and reliability of your final product.

Summary Table:

| Application | Key Process | Benefit |

|---|---|---|

| Ceramics | Firing/Sintering | Achieves hardness and durability |

| Glass | Melting/Fusing | Ensures clarity and purity |

| Glass | Annealing | Reduces internal stress and cracking |

| Quality Control | Material Testing | Validates thermal properties and performance |

Enhance your ceramics and glass production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your thermal processes and improve product quality!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination